Activated carbon recycling process in aspirin production

A technology of aspirin and activated carbon, which is applied in the field of medicine and chemical industry, can solve the problems of restricting the production of aspirin, not being able to reduce costs, stop working, etc., and achieve the effects of easy automatic control and operation, reducing raw material costs, and simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

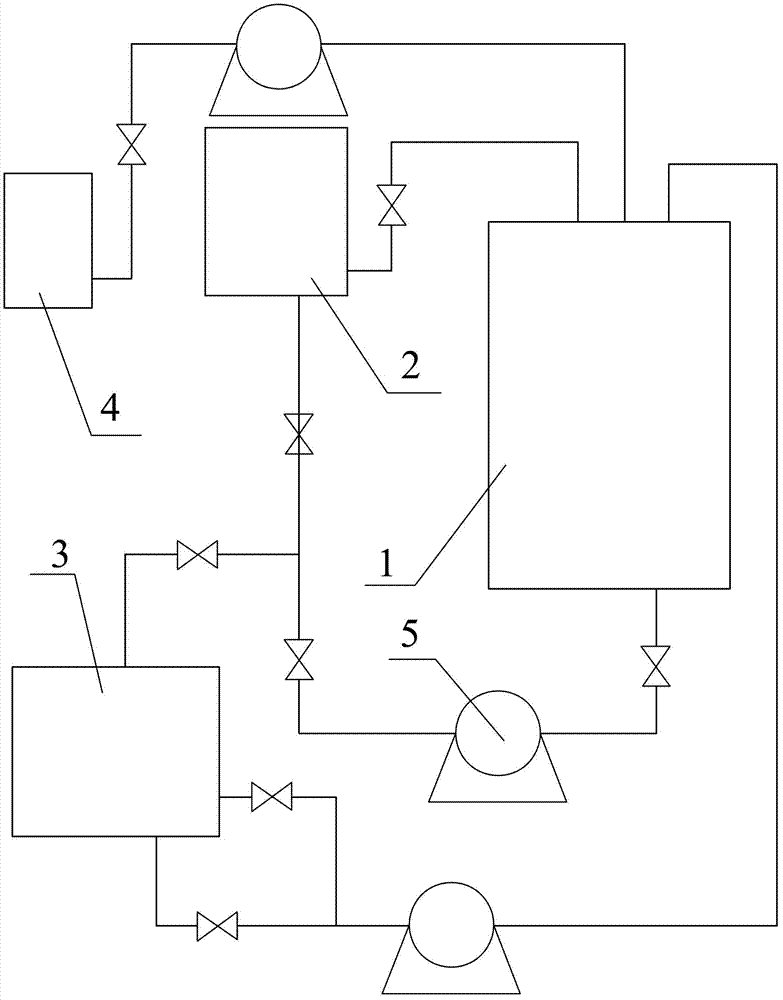

Image

Examples

Embodiment 1

[0036] 1. Open the liquid outlet valve at the bottom of the multifunctional filter 3, open the feed valve of the multifunctional filter 3 to feed the material, and after the refined filtration of sodium salicylate is completed, open the valve on the pipeline from filter 1 to multifunctional filter 3, and use An appropriate amount of soda water washes down the active carbon in the filter 2, and pumps it into the multifunctional filter 3 until the filter 2 sight glass flushing liquid is clarified, then stop the pump.

[0037] 2. Start to use feed pressure filtration, and the filtrate enters the sewage tank from the outlet pipe.

[0038] 3. Turn on the stirring rotation switch, and use the stirring rotation to assist in accelerating the filtration.

[0039] 4. Activated carbon regeneration: After the whole batch of 50kg (dry product) of activated carbon enters the multi-functional filter 3, close the feed valve, open the compressed air inlet valve on the multi-functional filter 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com