Novel finisher compiler tray

A finisher and assembler technology, used in thin material handling, printing, textiles, etc., to solve the problems of light-weight media bending, poor alignment, and increased driving force to reduce curl and paper leveling, curl height The effect of reducing accumulation and increasing the range of curling treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

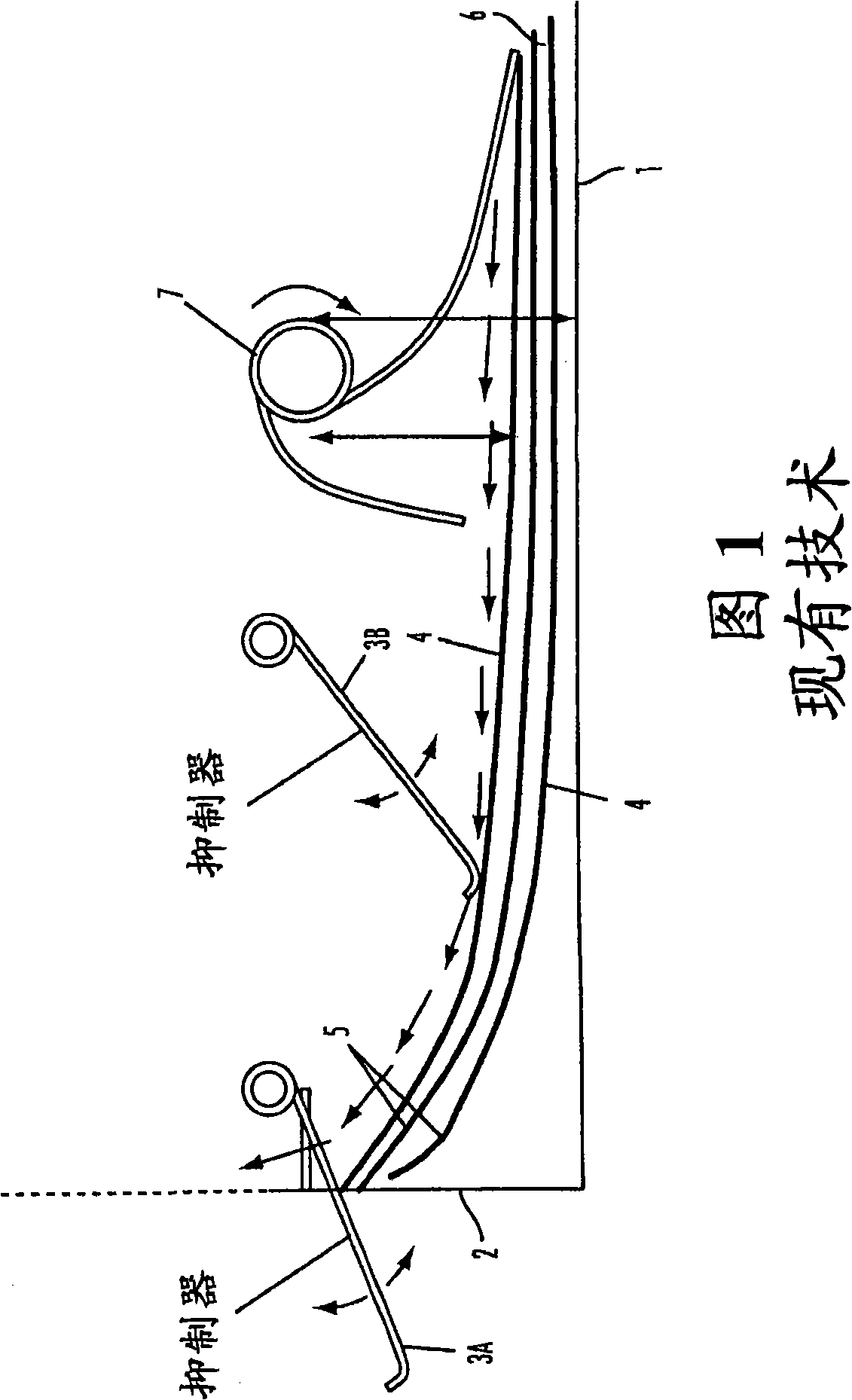

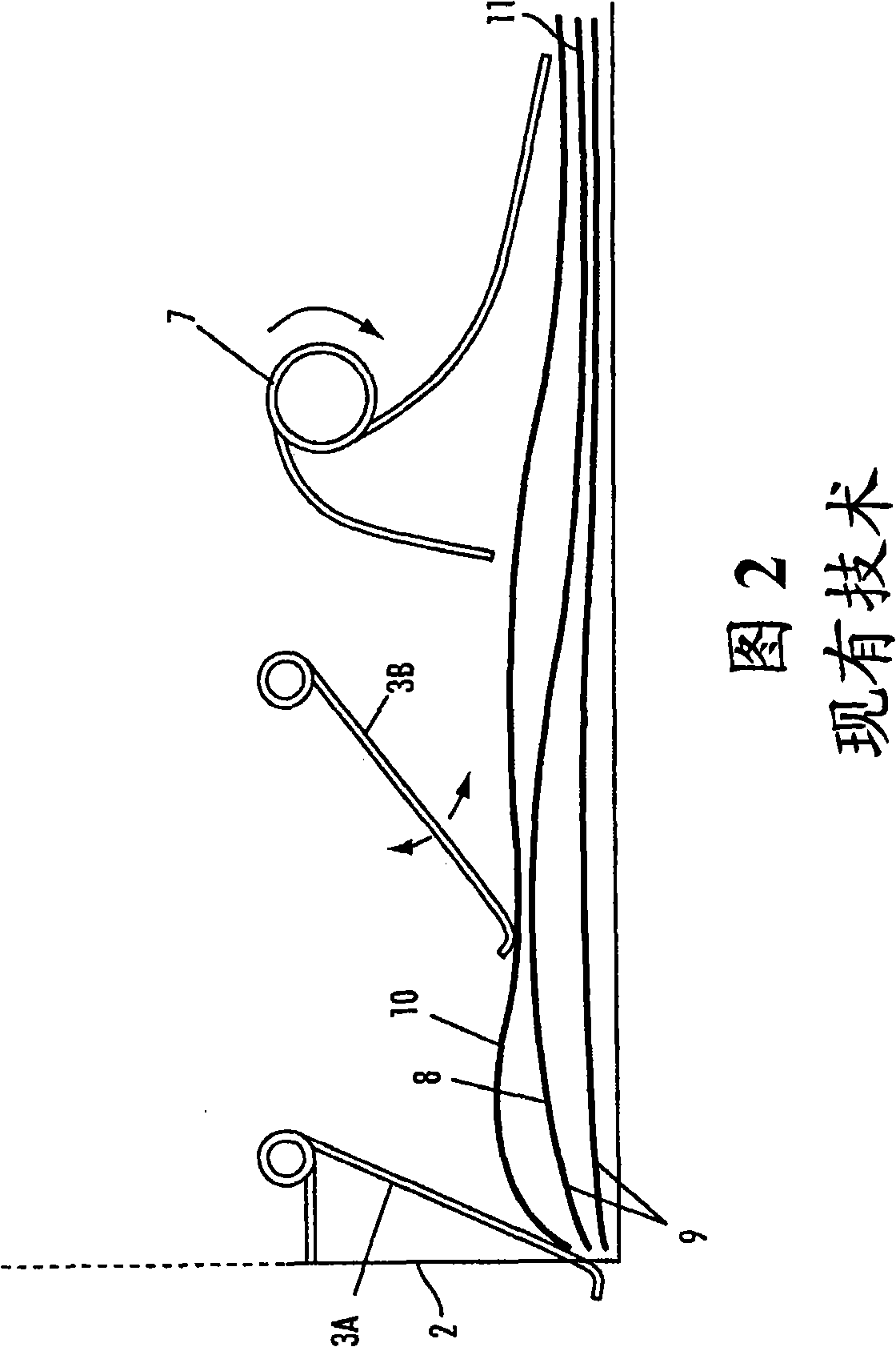

[0017] In Figure 1 , a side view of a compilation bracket 1 as used in the prior art is shown, having a rear guide (or compilation wall) 2 and pivotally mounted curl inhibitors 3A and 3B. As the sheet 4 enters the compilation tray 1, even with the curl suppressors 3A and 3B, the sheet 4 will often curl up at the leading edge 5 so that the sheet 4 becomes less likely to overlap at the trailing edge 6 of the sheet. The impeller 7 or other friction transmission component is used to drive the paper 4 forward against the rear guide 2 for alignment. Although in this prior art configuration the curl suppressors 3A and 3B reduce the tendency of the paper 4 to curl up, by their very nature of geometry they often permit reduced editing accuracy, thereby providing an inadequate stapling setup Alignment and often cause paper jams or damage to the marking system. As shown, the impeller 7 pushes the paper 4 into the carriage 1 and against the rear guide wall 2; as the stack rises, the curl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com