Cleaning method for hot spraying components and device thereof

A technology of parts and thermal spraying, which is applied in the field of cleaning, can solve the problems of shortened service life of metal parts, achieve the effects of reducing residual stress, reliable performance and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

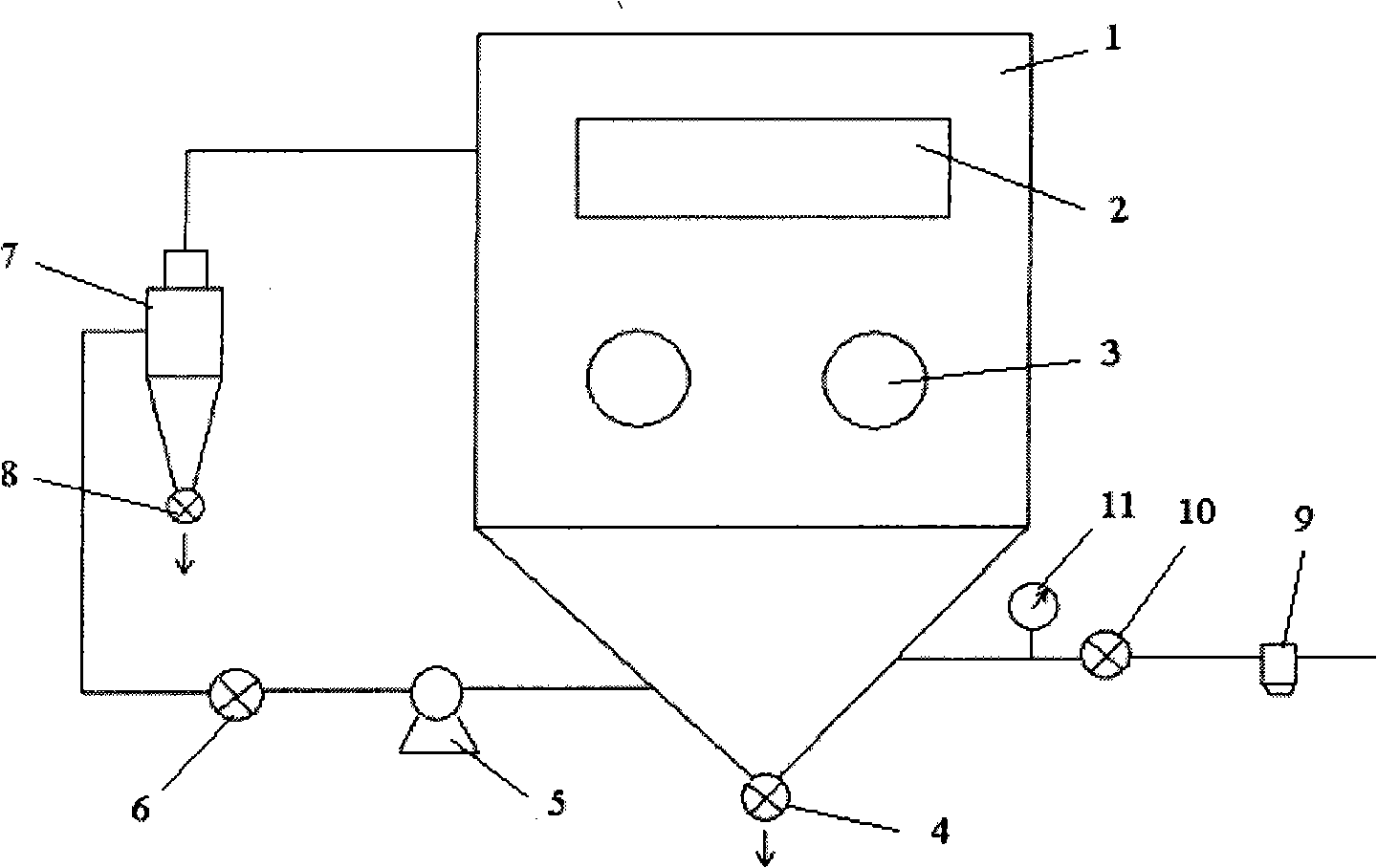

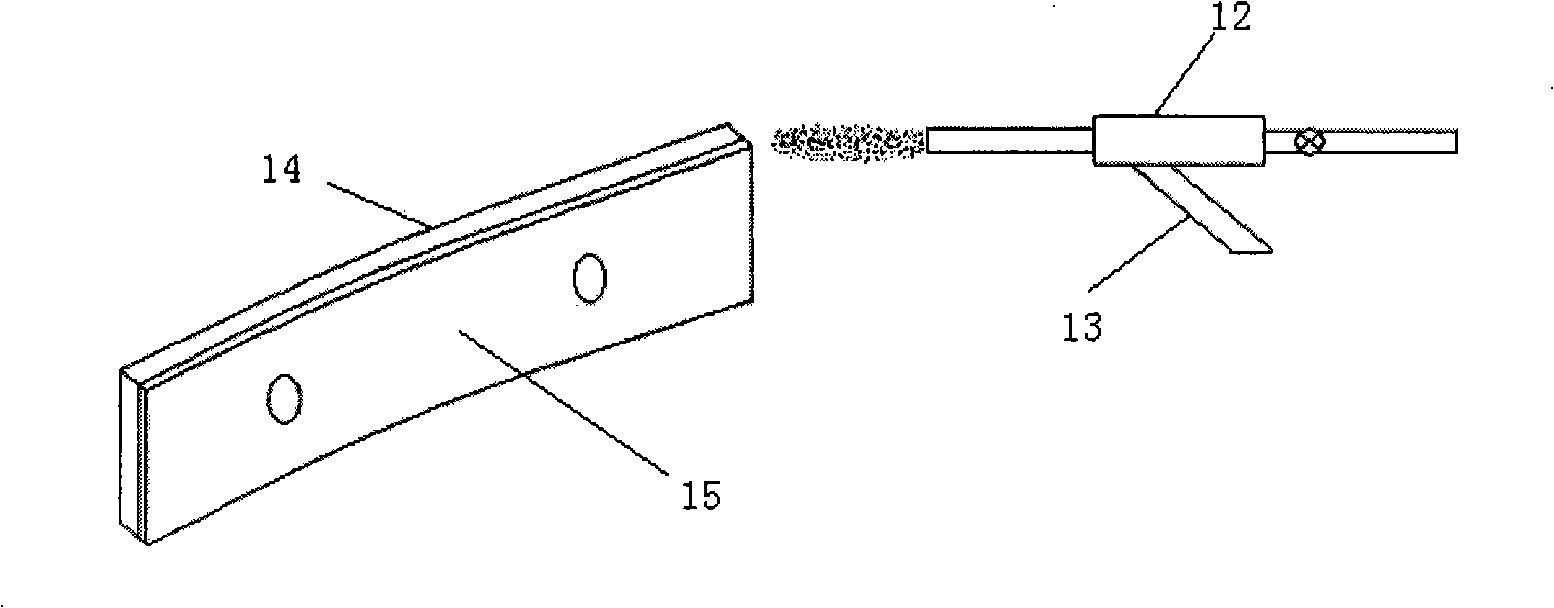

[0019] see figure 1 , the powder spraying box 1 is provided with two rubber gloves 3 and a window 2, the bottom of the powder spraying box 1 is provided with a fine powder replacement valve 4, the powder spraying box 1 is provided with a powder spraying gun 12, and the powder spraying gun 12 passes through the pressure regulating valve 10. The pressure gauge 11 and the compressed air filter 9 are connected to a high-pressure air source, and also connected to a powder suction pipe 13 connected to the powder container. The upper part of the powder spraying box 1 is connected to the cyclone separator 7, and the bottom of the cyclone separator 7 is provided Coarse sand / soil collection valve 8, the outlet of cyclone separator 7 are connected with powder spraying box 1 through regulating switch 6 and exhaust fan 5.

[0020] When cleaning the coating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com