Composite shot blasting device and method utilizing pellet kinetic energy and ultrasonic vibration

A technology of ultrasonic vibration and shot peening device, applied in the field of material processing, can solve the problems of limited surface material strengthening effect, reduced speed of pellets colliding with workpiece, affecting ultrasonic shot peening effect, etc., so as to improve strengthening efficiency and strengthening effect, and reduce damage. , the effect of severe plastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

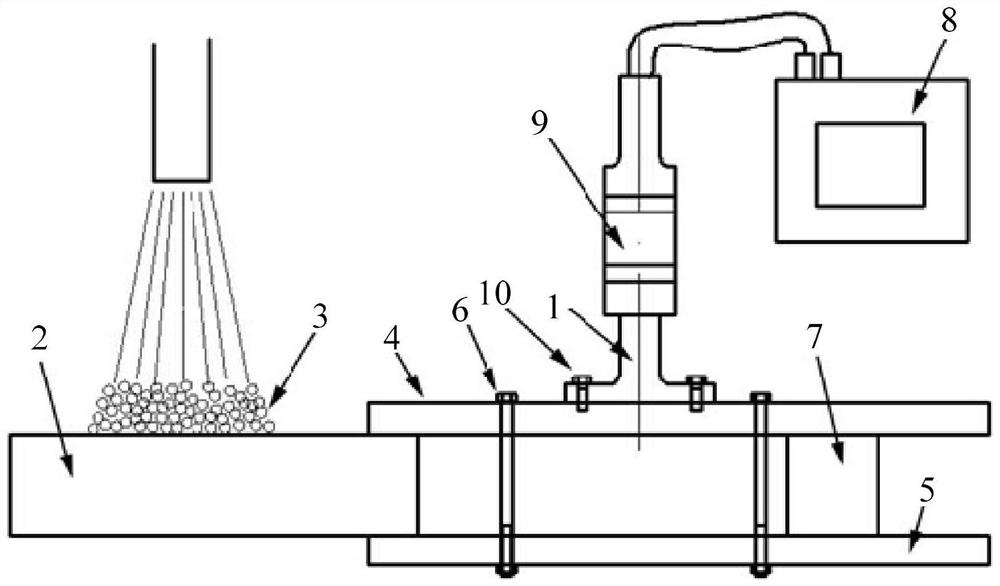

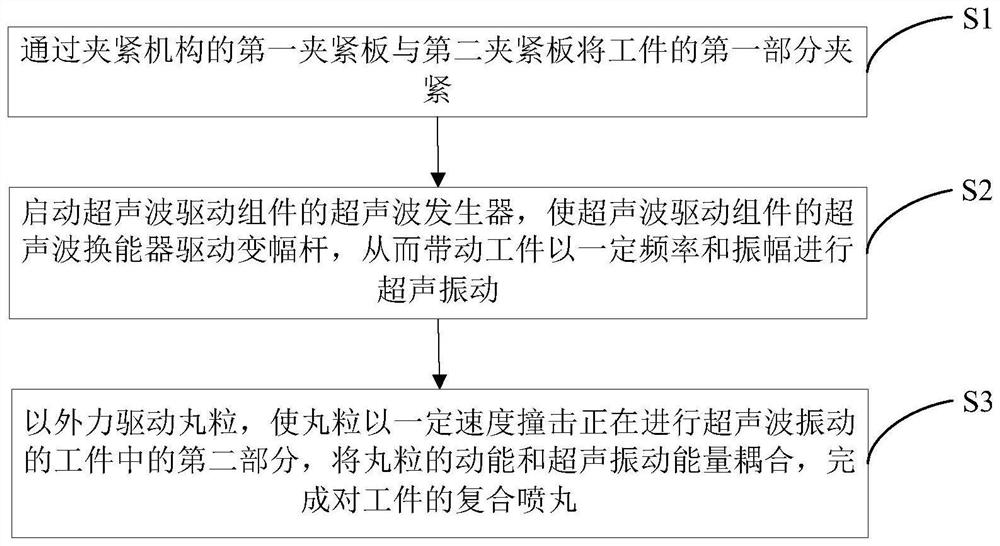

[0032] Such as figure 1 As shown, the present embodiment provides a compound shot peening device utilizing pellet kinetic energy and ultrasonic vibration, which device includes an ultrasonic drive assembly, a horn 1 and a clamping mechanism, and the clamping mechanism is used to clamp a part of the workpiece 2 Tight, the clamped part is the first part of the workpiece 2, the ultrasonic drive assembly is connected with the horn 1, the horn 1 is fixedly connected with the clamping mechanism, and the ultrasonic drive assembly is used to drive the horn 1 to drive the workpiece 2. Perform ultrasonic vibration; when the workpiece 2 is undergoing ultrasonic vibration, the external force drives the pellet 3 to hit the rest of the workpiece 2 except for the clamping mechanism, and the rest of the workpiece 2 is the second part of the workpiece 2 except for the clamping mechanism.

[0033] Further, the clamping mechanism includes a first clamping plate 4 and a second clamping plate 5, a...

Embodiment 2

[0043] The main feature of this embodiment is that the pellets 3 are driven by a mixture of compressed air and water. All the other are with embodiment 1.

Embodiment 3

[0045] The main feature of this embodiment is that the pellets 3 are driven by means of a drive mode in which the pellets 3 are thrown by relevant mechanical parts. All the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com