Continuous preparation method of cinnamon oil

A technology of cinnamon oil and cinnamon, which is applied in the direction of fat oil/fat refining, fat oil/fat production, fat production, etc. It can solve the problems of affecting the purity of volatile oil, high labor intensity, time and energy consumption, etc., and achieve timely separation and collection, reduce Labor intensity, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

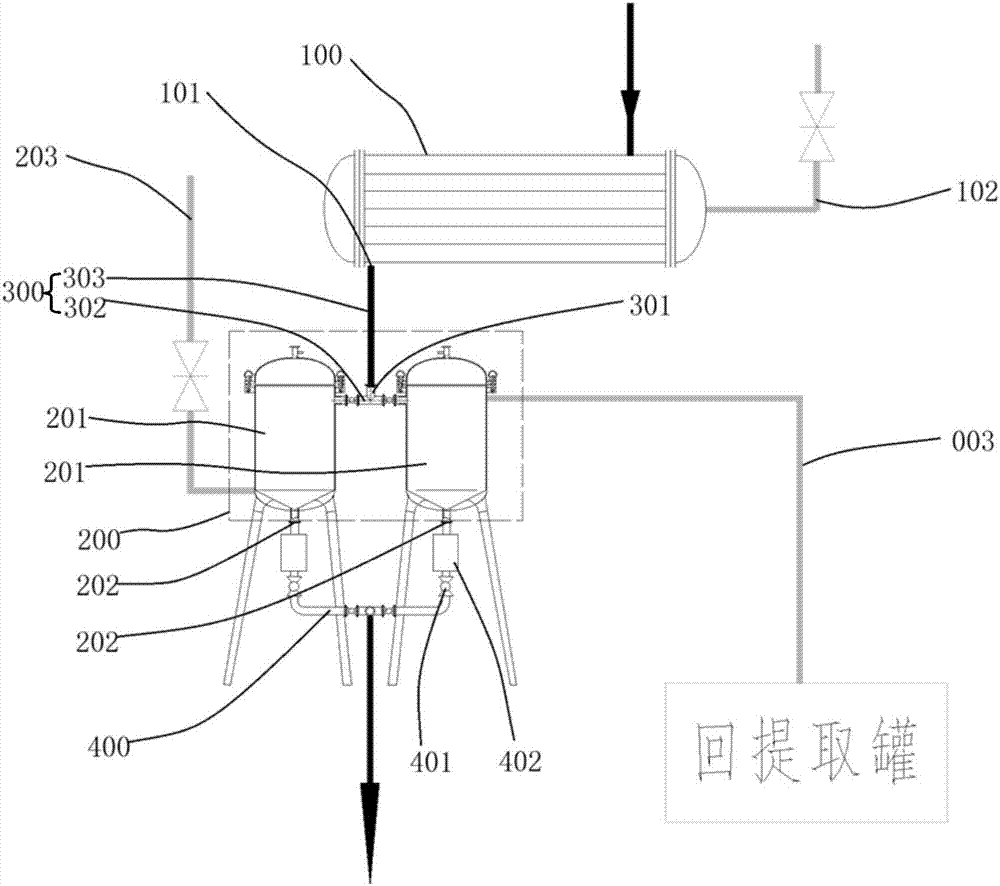

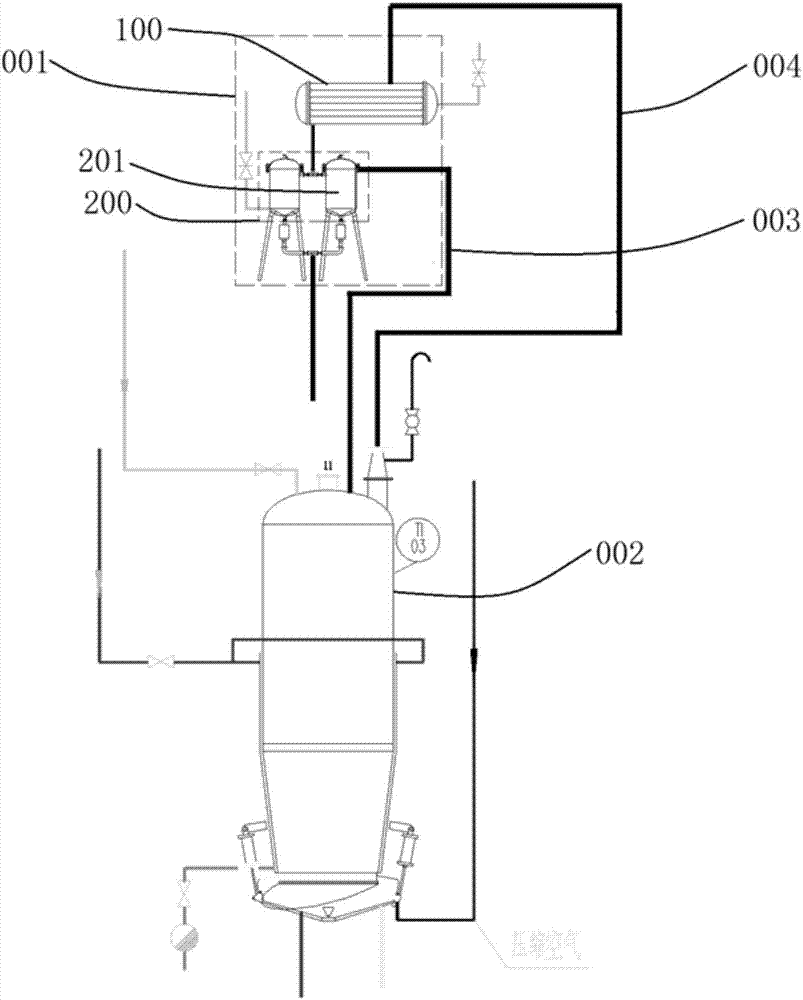

Method used

Image

Examples

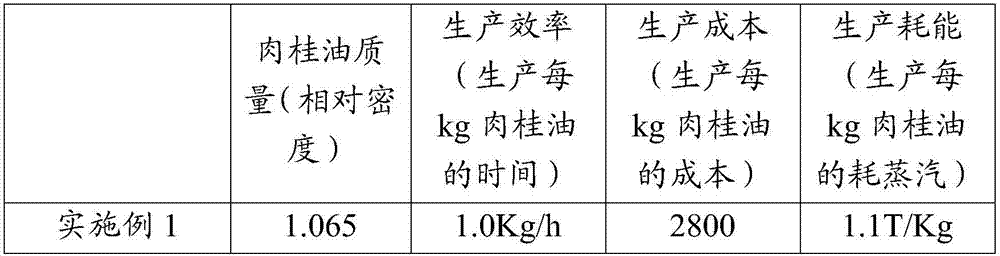

Embodiment 1

[0055] In this embodiment, a continuous preparation method of cinnamon oil is prepared by using the aforementioned device, and the steps are as follows:

[0056] (1) Preparation of oil-water mixed volatiles: chop 462kg of cinnamon with a medicine cutting machine, put it into the extraction tank 002, the volume of the extraction tank 002 is 3000L, add 10L of drinking water to wet the medicinal materials; Enter water vapor, distill cinnamon, and cinnamon oil is continuously volatilized and mixed with water vapor during the distillation process to form oil-water mixed volatiles; wherein, the pressure of the water vapor is 0.04~0.08Mpa (the steam pipeline is connected to the extraction tank 002 The pressure near the formed steam inlet), the temperature in the extraction tank is 95-100° C., and the pressure in the extraction tank 002 is maintained at 0 by feeding compressed air; meanwhile, the condensed water of the condensation device 100 is opened.

[0057] (2) Condensation: the ...

Embodiment 2

[0061] In this embodiment, a continuous preparation method of cinnamon oil is prepared by using the aforementioned device, and the steps are as follows:

[0062] (1) Preparation of oil-water mixed volatiles: chop 462kg of cinnamon with a medicine cutting machine, put it into the extraction tank 002, the volume of the extraction tank 002 is 3000L, add 10L of drinking water to wet the medicinal materials; Add steam to distill the cinnamon. During the distillation process, the cinnamon oil is continuously volatilized and mixed with water vapor to form oil-water mixed volatiles; wherein, the pressure of the water vapor is 0.10-0.15 MPa, and the temperature in the extraction tank is 98-103°C, and keep the pressure in the extraction tank 002 at 0; at the same time, turn on the condensed water of the condensing device 100.

[0063] (2) Condensation: the oil-water mixed volatiles are transported to the condensing device 100 through the oil-water mixed volatiles output pipe 004, and co...

Embodiment 3

[0067] In this embodiment, a continuous preparation method of cinnamon oil is prepared by using the aforementioned device, and the steps are as follows:

[0068] (1) Preparation of oil-water mixed volatiles: chop 462kg of cinnamon with a medicine cutting machine, put it into the extraction tank 002, the volume of the extraction tank 002 is 3000L, add 10L of drinking water to wet the medicinal materials; Add steam to distill the cinnamon. During the distillation process, the cinnamon oil is continuously volatilized and mixed with water vapor to form oil-water mixed volatiles; wherein, the pressure of the water vapor is 0.15-0.18Mpa, and the temperature in the extraction tank is 100-105°C, and keep the pressure in the extraction tank 002 at 0; at the same time, turn on the condensed water of the condensing device 100.

[0069] (2) Condensation: the oil-water mixed volatiles are transported to the condensing device 100 through the oil-water mixed volatiles output pipe 004, and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com