Method for manufacturing pattern and character on stainless steel plate

A stainless steel plate and pattern technology is applied in the field of making patterns and characters on the stainless steel plate to achieve the effects of no environmental pollution, strong contrast, and a simple and practical production method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1, taking the manufacture of a 60×50cm stainless steel sign as an example.

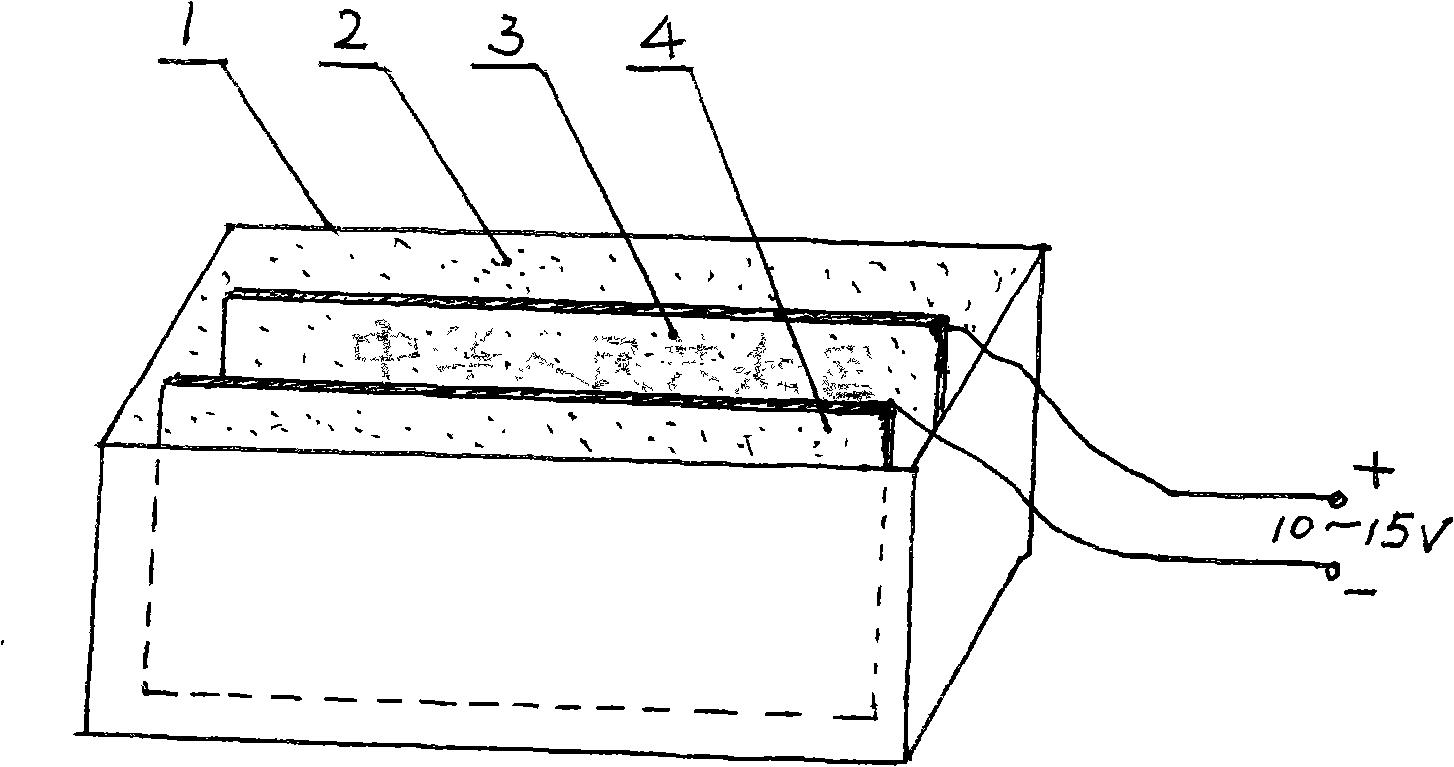

[0015] 1. Prepare NaCl solution 2 according to the weight ratio of NaCl: water = 1:8 and put it into the dissolution tank 1.

[0016] 2. Cut out two stainless steel plates of 60×50cm, and use one of them as a plaque substrate 3 to polish to a mirror surface, clean it with acetone, and then paste the required font engraved with a self-adhesive plastic film as a protective layer , the periphery of the glyph is sticky to prevent the solution from immersing, and another stainless steel plate is used as the negative plate 4;

[0017] 3. Use the plaque substrate 3 as the positive electrode, and put it into the dissolution tank in parallel with the negative electrode plate 4. It is required that the side of the plaque substrate 3 with a font face towards the negative electrode plate 4, and the distance between the two stainless steel plates is 0.8cm;

[0018] 4. Connect the positive and ne...

Embodiment 2

[0019] Embodiment two, take making the stainless steel door plate of 20 * 20cm as an example.

[0020] 1. Prepare NaCl solution 2 according to the weight ratio of NaCl: water = 1:10 and put it into the dissolution tank 1.

[0021] 2. Cut out two 20×20cm stainless steel plates, and use one of them as a plaque substrate 3 to polish to a mirror surface, clean it with acetone, and then paste the required fonts engraved with a self-adhesive plastic film as a protective layer , the periphery of the glyph is sticky to prevent the solution from immersing, and another stainless steel plate is used as the negative plate 4;

[0022] 3. Put the plaque substrate 3 as the positive electrode and the negative electrode plate 4 into the dissolving tank in parallel. It is required that the side of the plaque substrate 3 with the font face towards the negative electrode plate 4, and the distance between the two stainless steel plates is 0.5cm;

[0023] 4. Connect the positive and negative poles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com