High power light-emitting diode illuminating source heat radiating device

A technology of light-emitting diodes and heat-dissipating devices, which is applied to semiconductor devices of light-emitting elements, light sources, cooling/heating devices of lighting devices, etc. , High luminous efficiency and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with the accompanying drawings and specific examples for further description

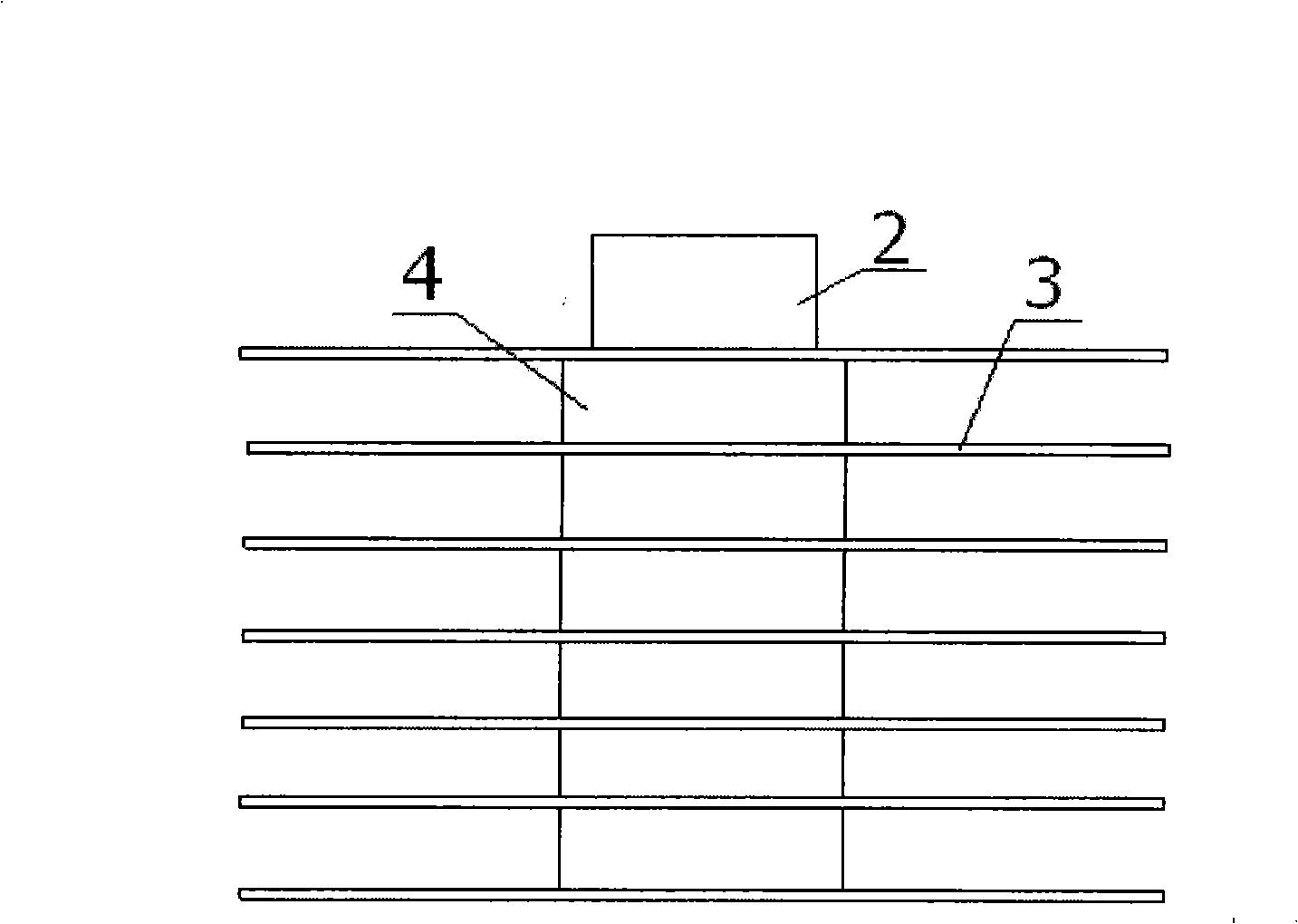

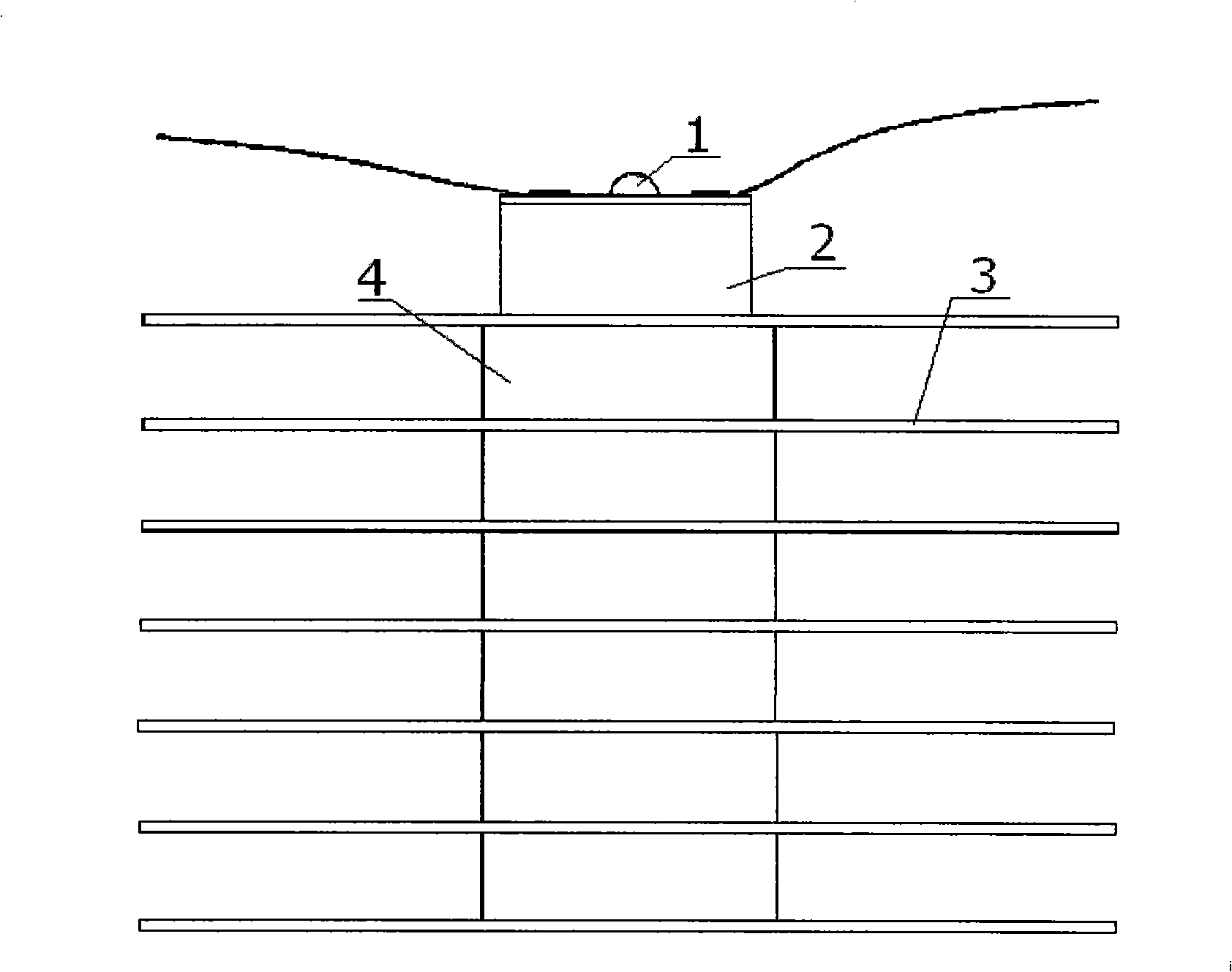

[0020] Such as figure 1 and 2 As shown, the heat conduction device of the high-power LED light source of the present invention includes a pure copper heat sink body 2 for installing a high-power LED light source 1 on the top, a pure aluminum heat sink 3 and a pure aluminum fastening ring 4; The aluminum heat sink 3 is fixed on the outer periphery of the pure copper heat conduction heat sink body 2 through the pure aluminum fastening ring 4 . The cooling fins 3 are fastened and embedded on the pure copper heat conduction heat sink body 2 through the hoop rings 4 in a manner of equidistant distribution.

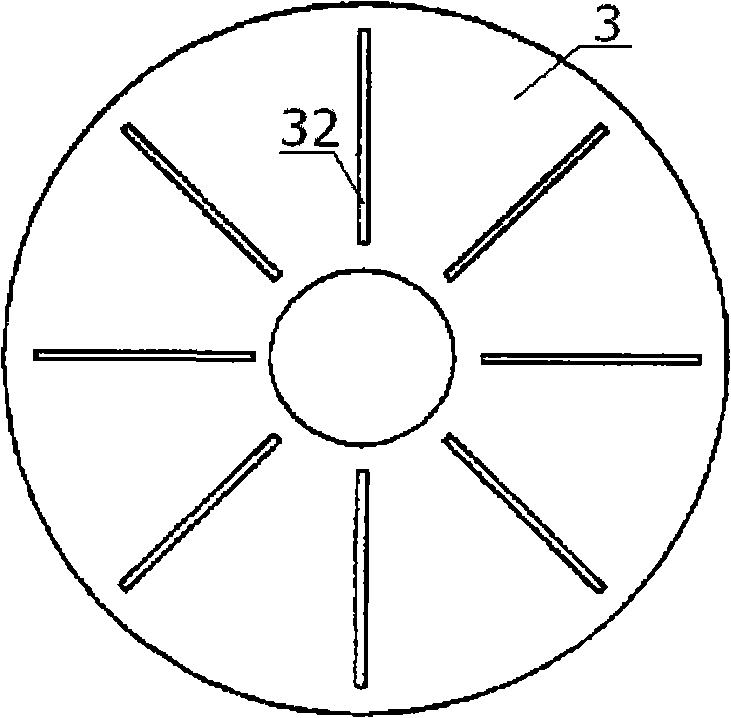

[0021] Certainly, in order to further improve heat dissipation efficiency, heat dissipation holes 31 or heat dissipation grooves 32 or heat dissipation holes 31 and heat dissipation grooves 32 may also be formed on the heat dissipation fin. The cross section of the pure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com