Preparation and application of composite oxide solid acid air bactericide

A composite oxide and solid acid technology, applied in the direction of fungicides, applications, biocides, etc., can solve the problems of large damage to the human body, serious damage to the skin, stabbing eyes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

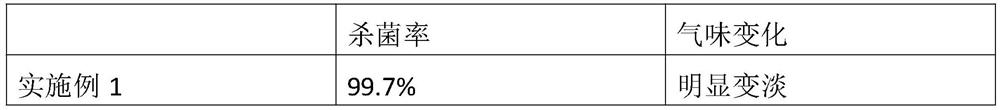

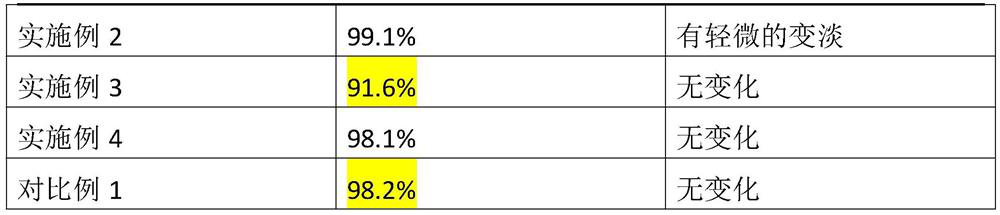

Examples

Embodiment 1

[0025] A kind of preparation of composite oxide solid acid air bactericide comprises the following steps:

[0026] (1) Get 55 parts of Pinus pine branches and leaves, 13 parts of 100 root roots, 15 parts of tripterygium twig roots, 15 parts of Cnidium chinensis, 11 parts of yellow rhododendrons by weight, cut into small sections, weigh the quality, and carry out in a steam distillation pot Distill, then condense the gas after distillation in the steam distillation pot and pass through the oil-water separator to separate material A;

[0027] (2) Take 30 parts by weight of step (1) to separate and obtain material A, put it into a reaction tank, then add 15 parts of composite oxide solid acid and 8 parts of coupling agent respectively, mix and stir, and heat to react;

[0028] (3) Take 25 parts of the reacted solution in step (2) by weight, pour it into a mixing tank, then add 8 parts of chlorine dioxide, 30 parts of distilled water, seal and mix, after stirring, you can compoun...

Embodiment 2

[0041] The same as embodiment 1 is not repeated, and the difference with embodiment 1 is:

[0042] The composite oxide solid acid is taken in 3 parts.

Embodiment 3

[0044] The same as embodiment 1 is not repeated, and the difference with embodiment 1 is:

[0045] The composite oxide solid acid takes 20 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com