Black ceramic composite ceramic sun plate

A technology of composite ceramics and solar panels, which is applied in the field of manufacturing ceramic products and utilizing solar energy with ceramic products, can solve the problems of complex structure and manufacturing process of vacuum glass tube heat collector, attenuation of sunlight absorption rate, and high price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] 1.CoO 20%,Cr 2 o 3 18%, Cuo 15%, Fe 2 o 3 22%, MnO 2 25% (by weight) is evenly mixed and then sintered at 1240° C. for 2 hours, and the sintered block is crushed to 120 mesh, which is a ceramic black colorant.

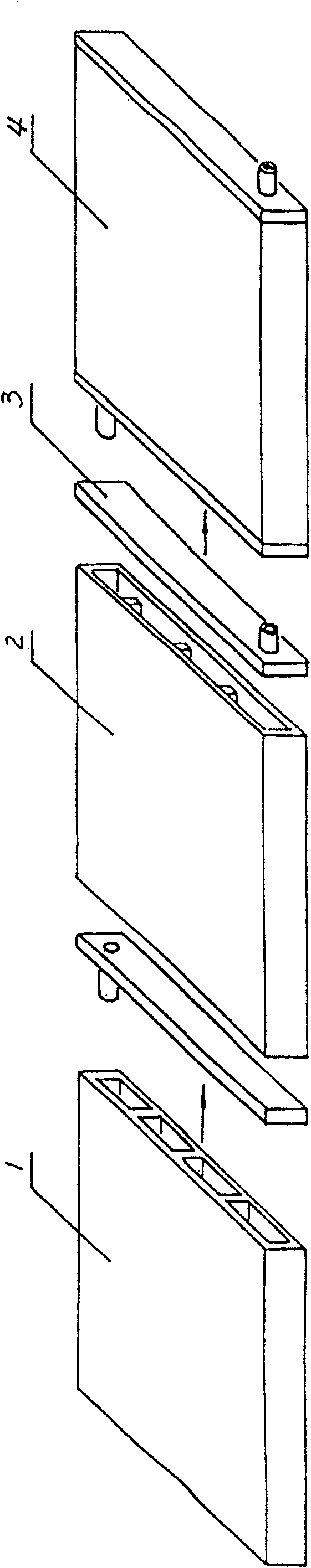

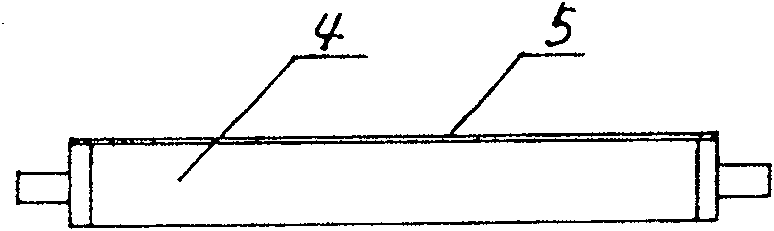

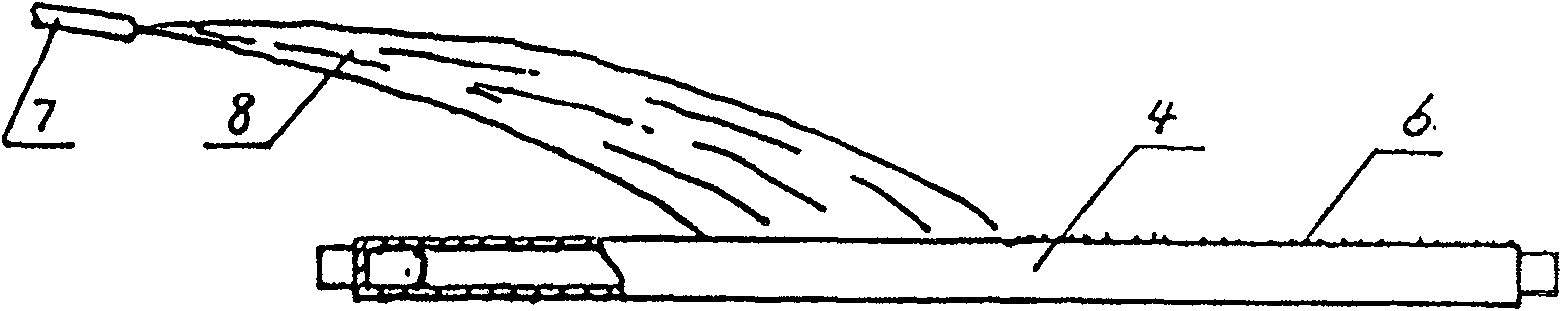

[0022] 2. With 35 parts of ceramic black coloring agent described in embodiment 2, 40 parts of Datong soil, 5 parts of feldspar, talcum 10%, 10 parts of burnt gemstones, add water and ball mill to 250 order mud, with compressed air mud sprays on drying On the surface of the hollow ceramic solar panel blank with a length x width of 1200 x 800 mm, the air pressure is 0.6Mpa, the spray gun is sprayed downward at an angle of 70° to the vertical plane, and the distance between the spray gun and the surface of the blank is 300 mm, and the single gun is progressively scanned and sprayed For 2 minutes, the sprayed droplets at the initial stage are moisture-absorbed and solidified by the plate surface, and the droplets sprayed on the accumulation body are moisture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com