Kneading extruding and granulating equipment

An extrusion granulation and equipment technology, applied in the field of kneading extrusion granulation equipment, can solve the problems of unable to continue the process, reduce production efficiency, affect the normal progress of extrusion granulation, etc., to improve production efficiency and finished product quality, operation Convenient, compact effect

Active Publication Date: 2010-12-01

曹永良

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In particular, the kneading equipment and the extrusion granulation equipment belong to the processing equipment of two adjacent processes in terms of technology, but because many technical problems cannot be solved before, they have been working independently

On the one hand, the turnover of transferring the semi-finished products after kneading processing to the extrusion granulation equipment reduces the production efficiency

On the other hand, and more importantly, some materials (mixed materials) have unexpected changes in physical and chemical properties during the turnover process after they are discharged from the kneader, which affects the normal progress of extrusion granulation in the later stage, and even Unable to continue the later process

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

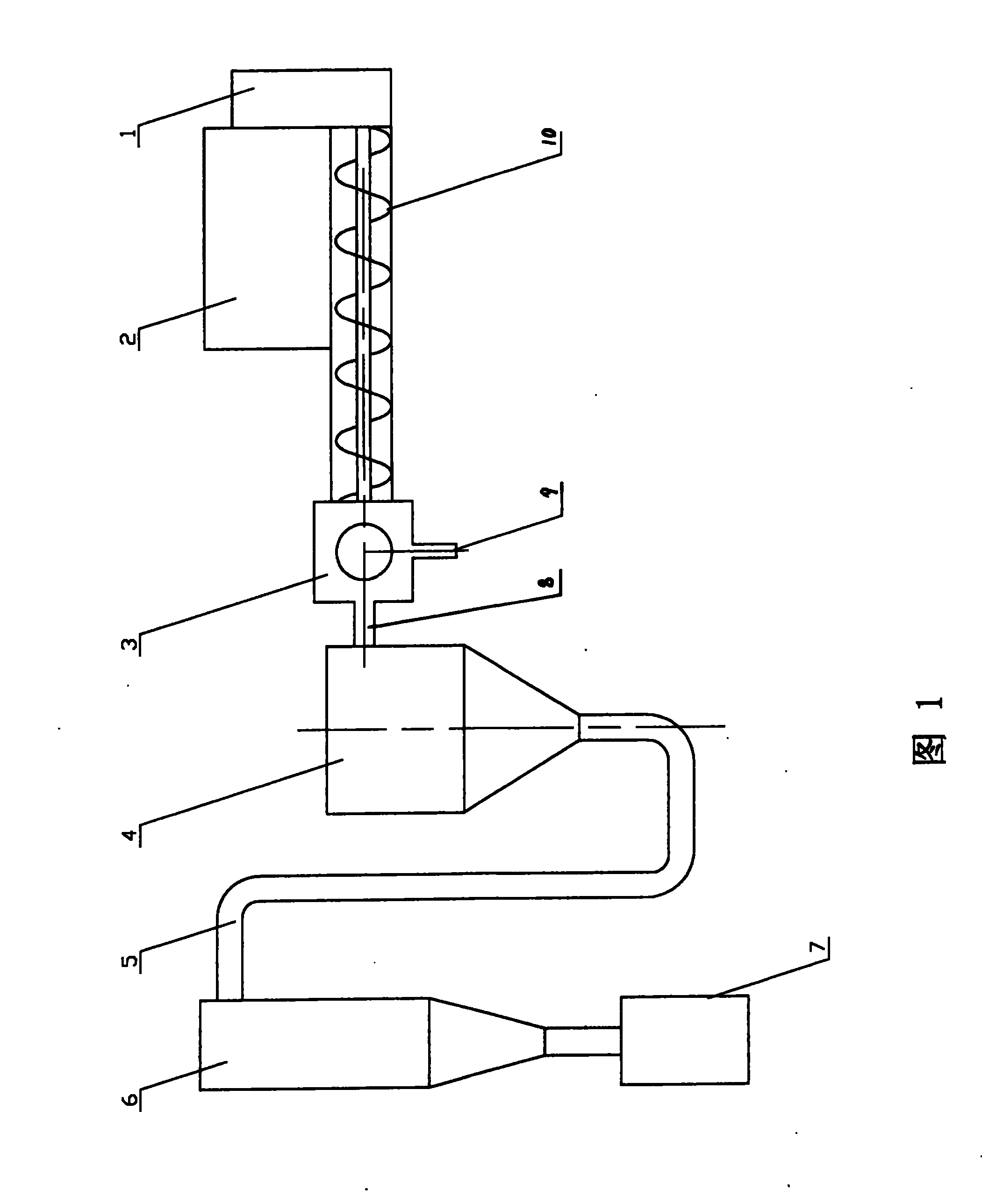

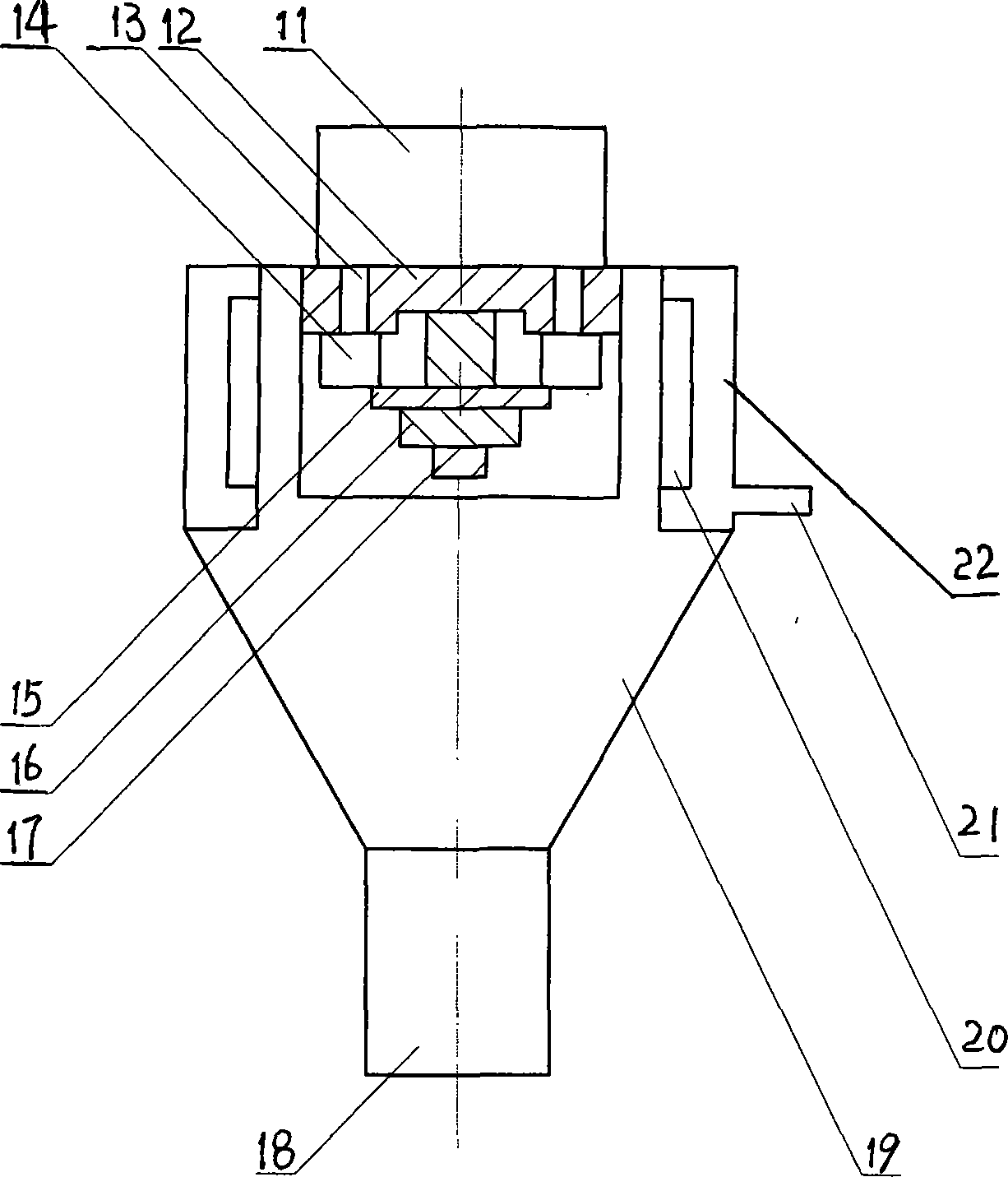

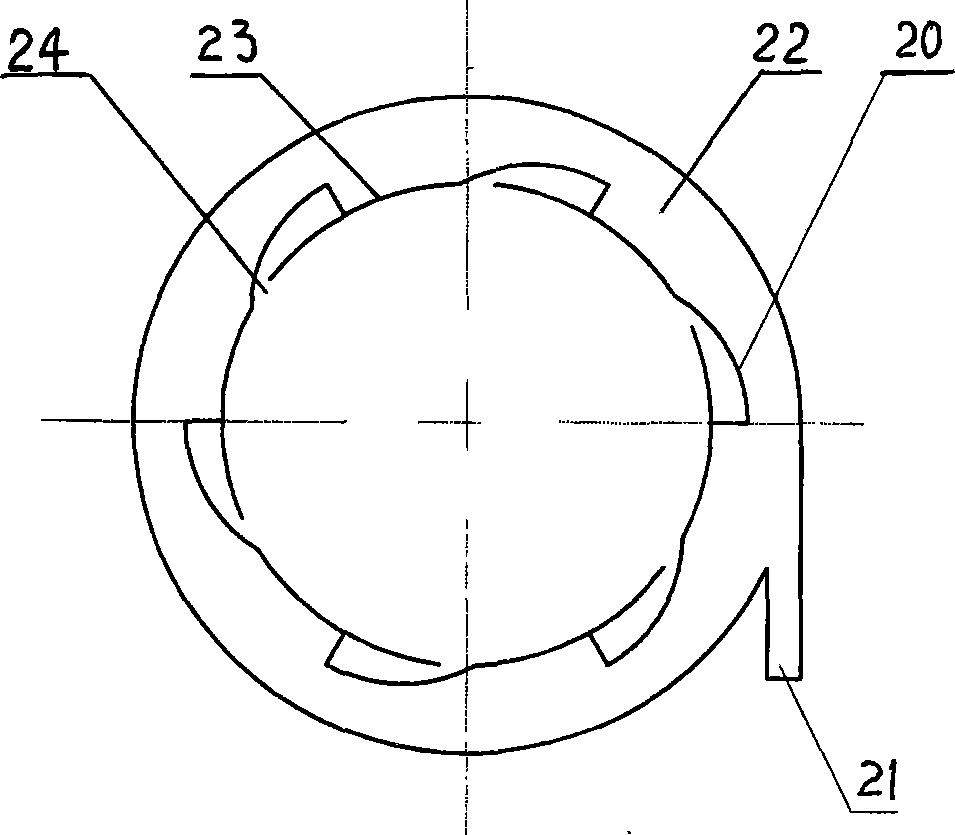

The invention relates to a kneading extrusion pelletizing apparatus, comprising an extrusion screw (10) arranged under the central part between two kneading stirring paddles; wherein, the axes of the kneading stirring paddles are parallel to the axis of the extrusion screw (10). The discharge end of the kneading extruder (2) is connected with a distributing valve (3) with a first discharge opening (9) and a second discharge opening (8), wherein the second discharge opening (8) is connected with a granulating apparatus. As kneading and extrusion are integrated into an organic whole, the unexpected physical and chemical performance changes of the mixed materials in the circulation process, after the mixed materials are discharged form the kneader, which can influence the later granulation or even cause interruption of the later operation, are avoided; the granulation productivity and product quality are improved.

Description

Kneading extrusion granulation equipment technical field The invention relates to a granulation equipment, in particular to a kneading extrusion granulation equipment. Background technique Existing granulation equipment, kneading equipment and extrusion equipment are generally independent of each other. In particular, the kneading equipment and the extrusion granulation equipment belong to the processing equipment of two adjacent processes in terms of technology, but because many technical problems cannot be solved before, they have been working independently. On the one hand, the turnover of transferring the kneaded semi-finished products to the extrusion granulation equipment reduces the production efficiency. On the other hand, and more importantly, some materials (mixed materials) have unexpected changes in physical and chemical properties during the turnover process after they are discharged from the kneader, which affects the normal progress of extrusion granulation...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B01J2/20

Inventor 曹永良

Owner 曹永良

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com