Centrifugal separator disk plate

A technology of centrifugal separation and discs, which is applied in centrifuges and other directions, can solve the problems of affecting the separation process and the large influence of dispersed phase flow, and achieve the effects of improving separation efficiency, increasing production capacity, and shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

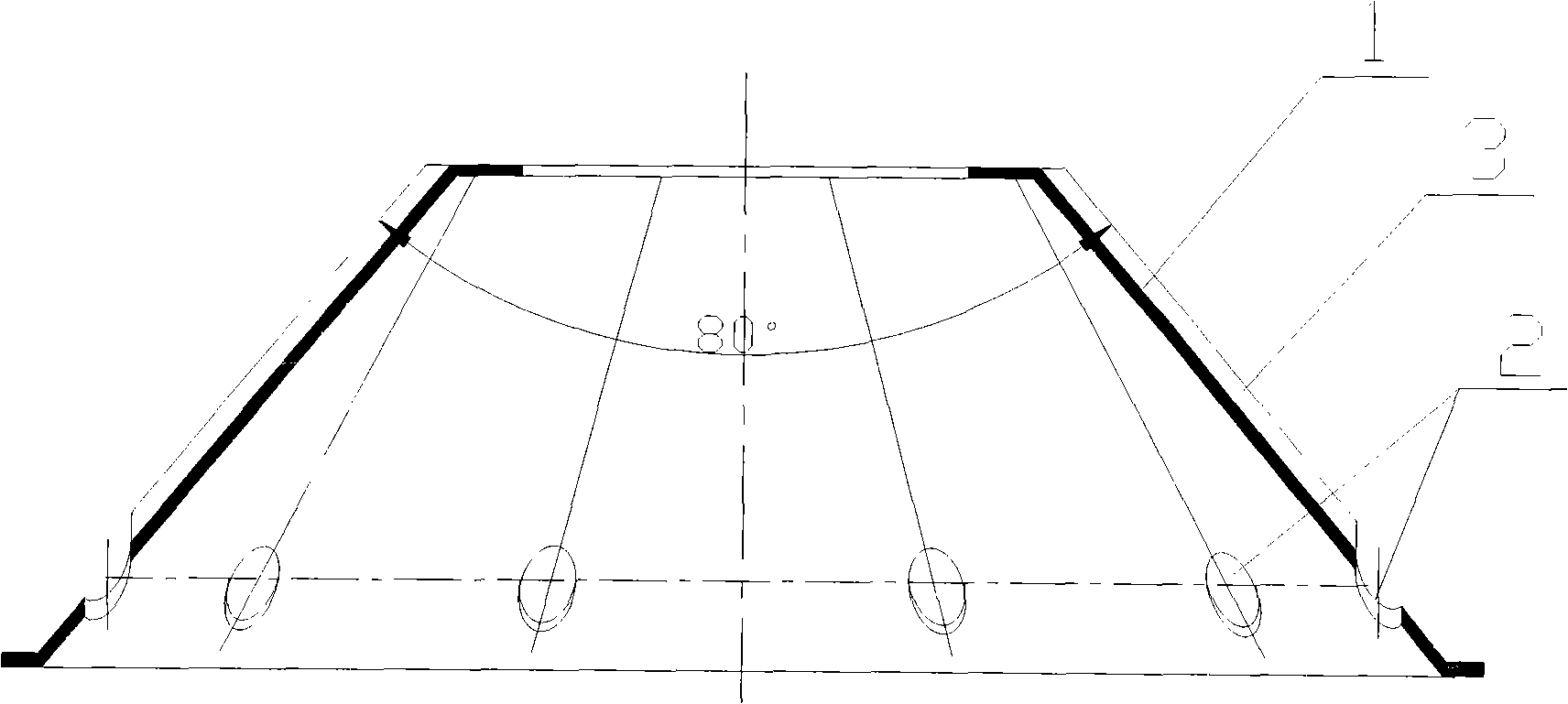

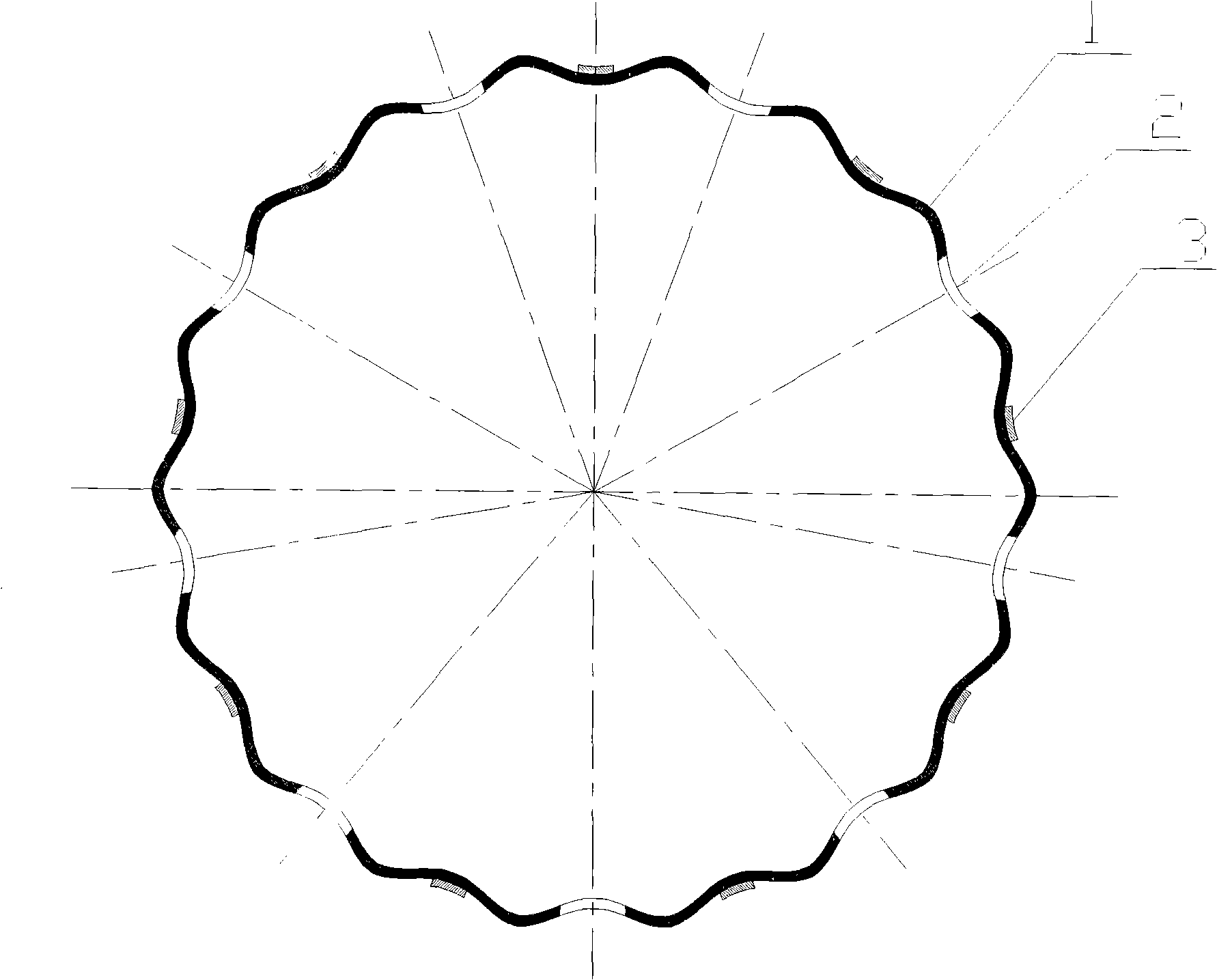

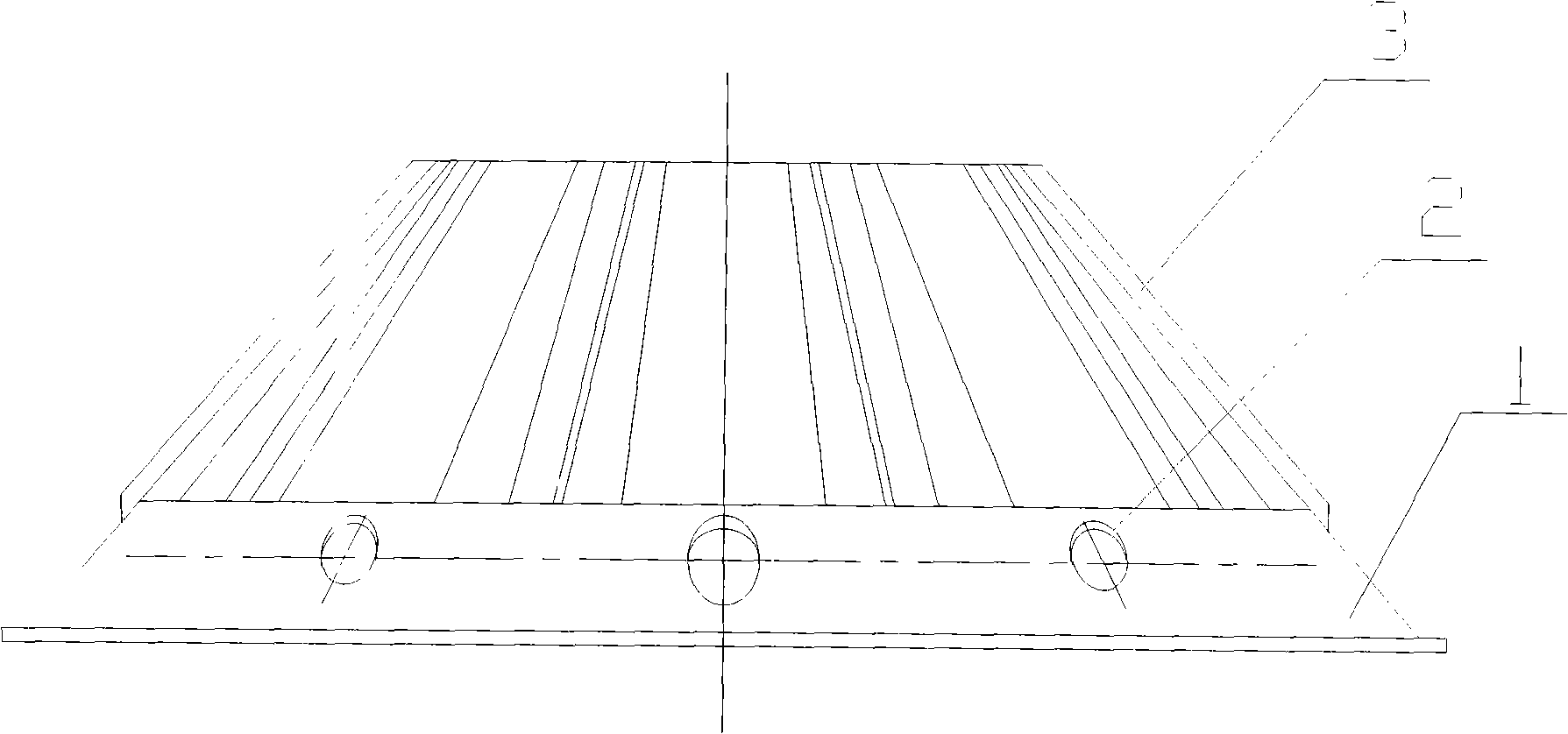

[0019] The disc composition of the centrifuge that present embodiment provides is as follows figure 1 , figure 2 and image 3 shown. The disc includes a disc body (1), several feeding holes (2) and several ribs (3), wherein the disc body is corrugated along the circumferential direction and straight or helical along the height direction, but No corrugation is set in the area from the big end face to the diameter of the inner big end of the conical disc that is 0.1 times from the big end face. A feeding hole (2) or a rib (3) is arranged in the inner recess of the disc. The feeding holes (2) and ribs (3) are alternately arranged in the circumferential direction.

[0020] Wherein the full cone angle of the corrugated conical disc is 80°.

[0021] The corrugation of the corrugated conical disc is sinusoidal, the number of waves is 16-32, and the amplitude is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com