Corrugated pipe and end mould fixing method

A fixing method and corrugated tube technology, which is applied in the direction of hose connection devices, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of large damage to the end formwork, increase the number of end formwork sets, and large repair workload, etc., to achieve Less damage, less repair work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

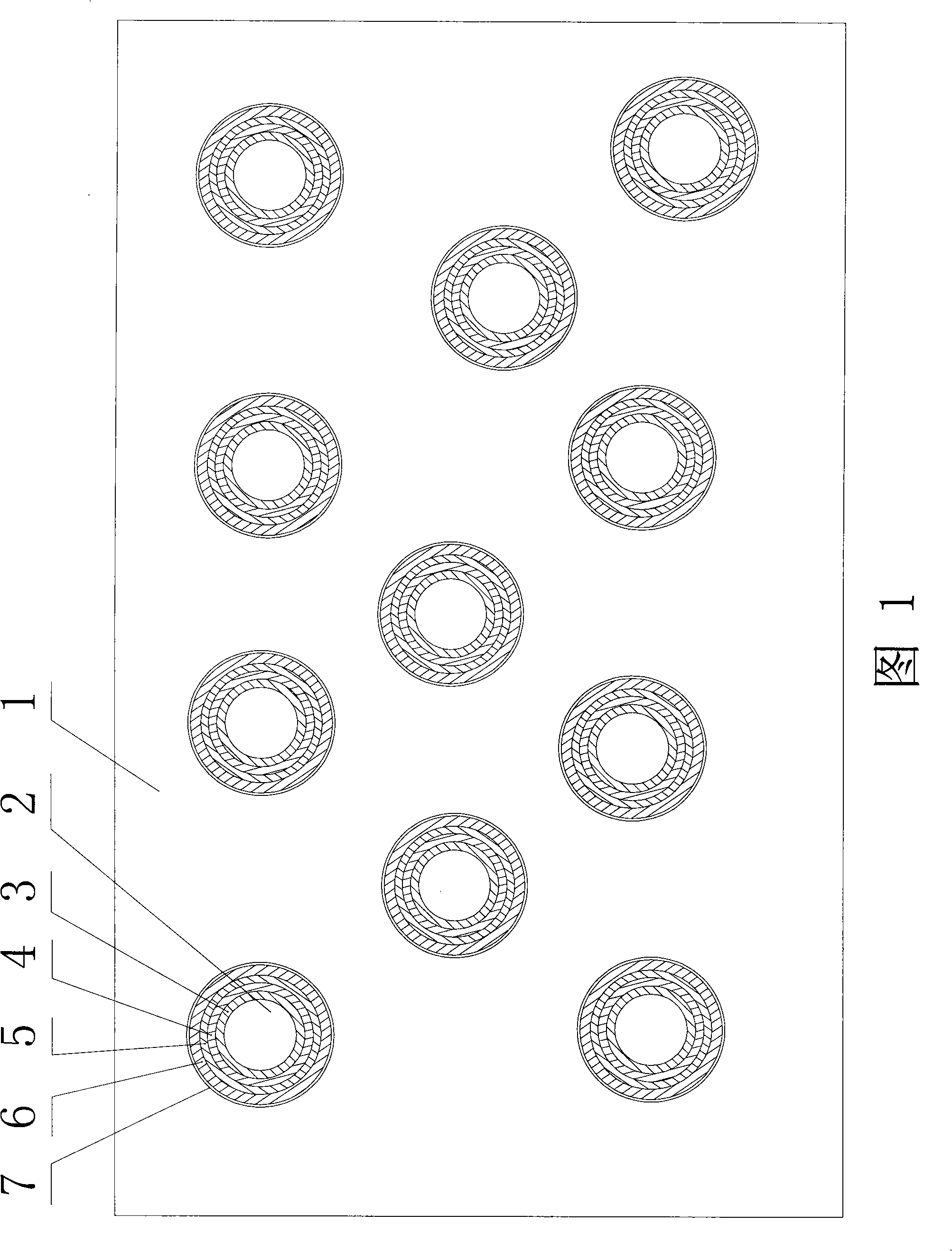

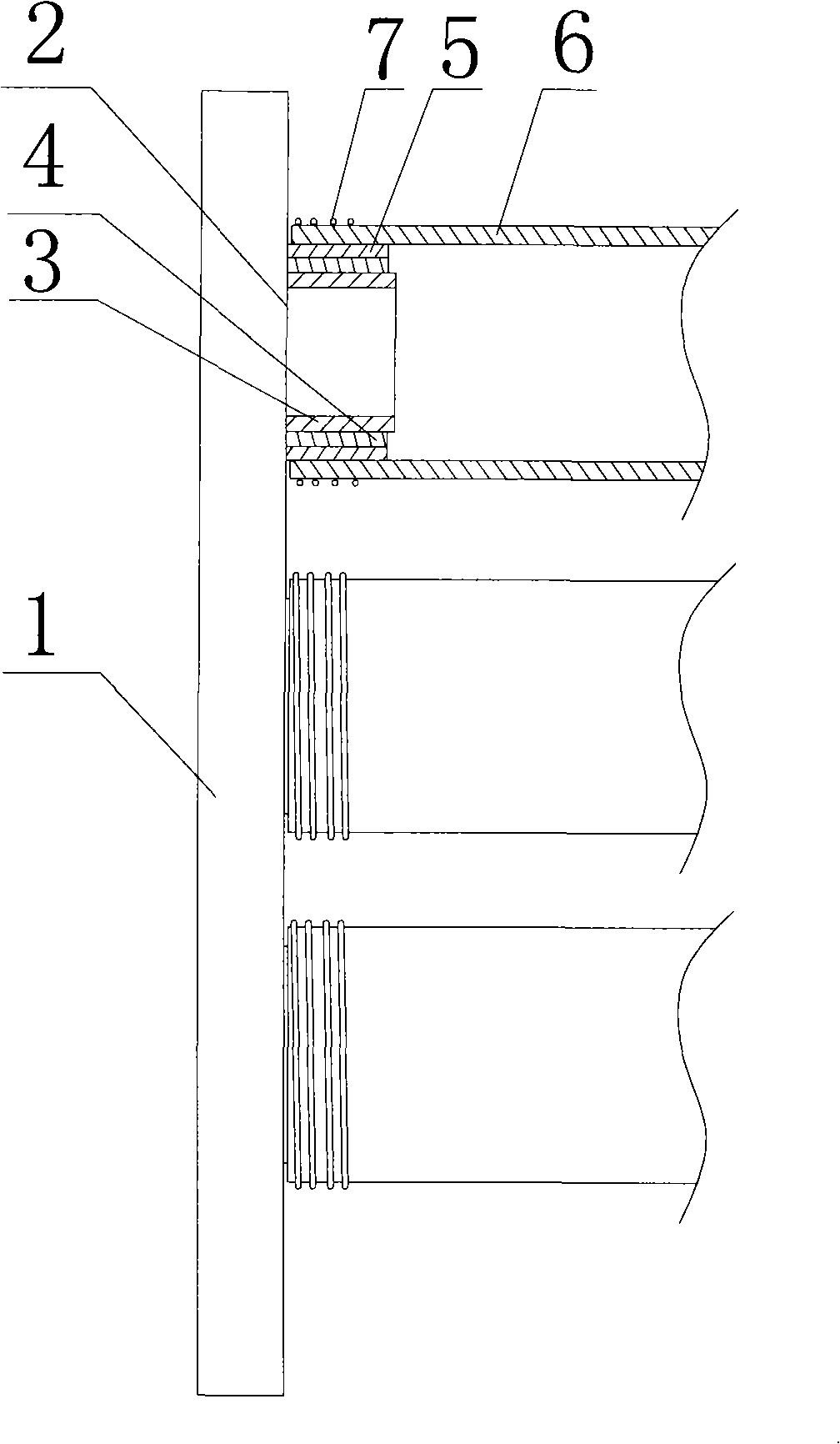

[0010] Figure 1, figure 2 Shown, a kind of corrugated pipe and end die fixing method, it comprises the following steps: select the connecting pipe 3 (such as: the diameter of corrugated pipe 6 is 100mm, the diameter of connecting pipe 3 is 95mm, the connecting pipe 3 is 50mm), and the connecting pipe 3 is a black iron pipe, because the black iron pipe is smaller than the corrugated pipe, this is convenient for docking. On the end formwork 1 of the end formwork, draw a hole circle 2 on the end formwork with chalk according to the number of bellows in the box girder section and the center coordinate position of each bellows, and then click on each hole circle 2 on the end formwork 1 Weld the connecting pipe 3 so that the central coordinate position of the pipe hole of the connecting pipe 3 corresponds to the central coordinate position of the hole ring 2; for different sections, only the connecting pipe (black iron pipe) 3 Spot welding is easy to operate, and the end template i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com