Position detector

A detector and target detection technology, applied in the direction of electric/magnetic position measurement, instruments, measuring devices, etc., can solve the problems of high-speed performance limitations, achieve high precision and speed, high speed, and improve the effect of interpolation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Embodiments of the present invention will be described below with reference to the drawings.

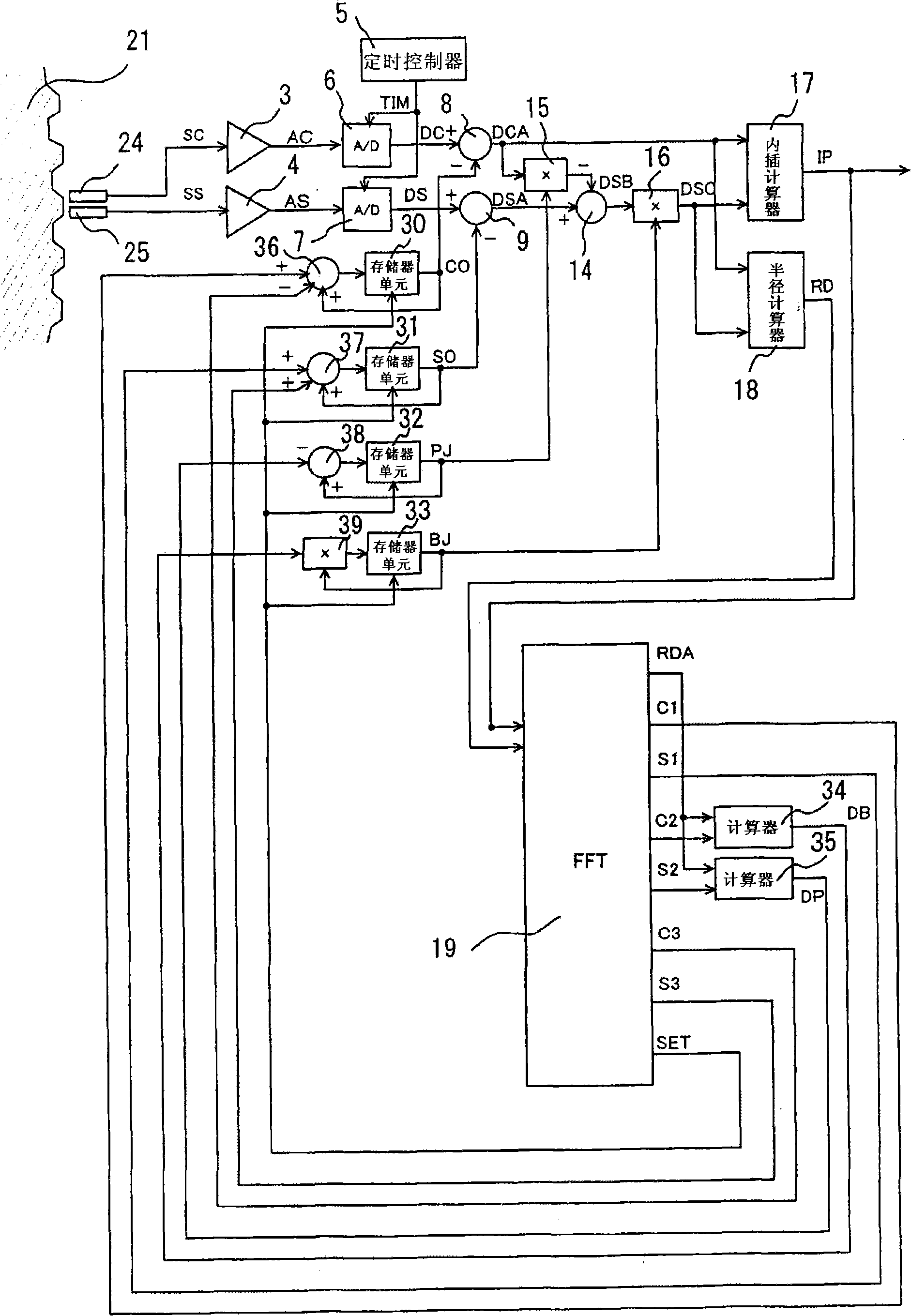

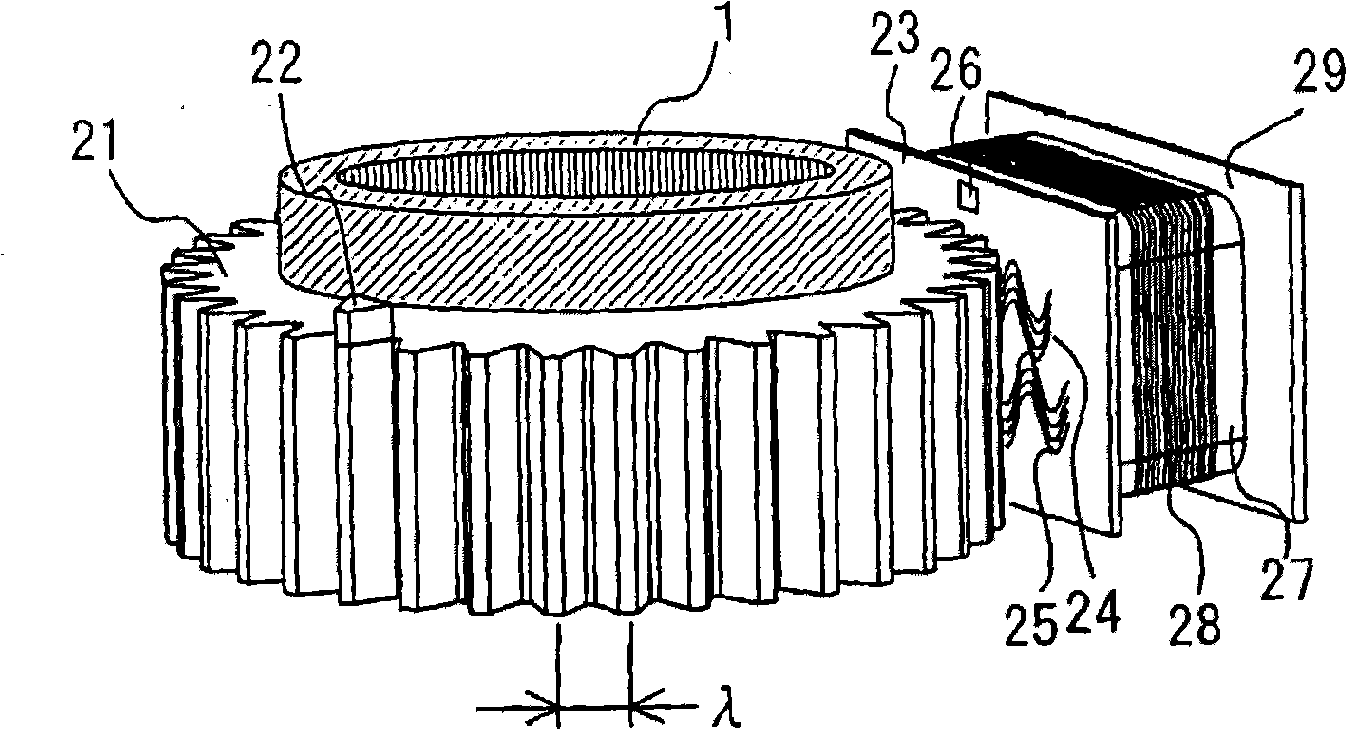

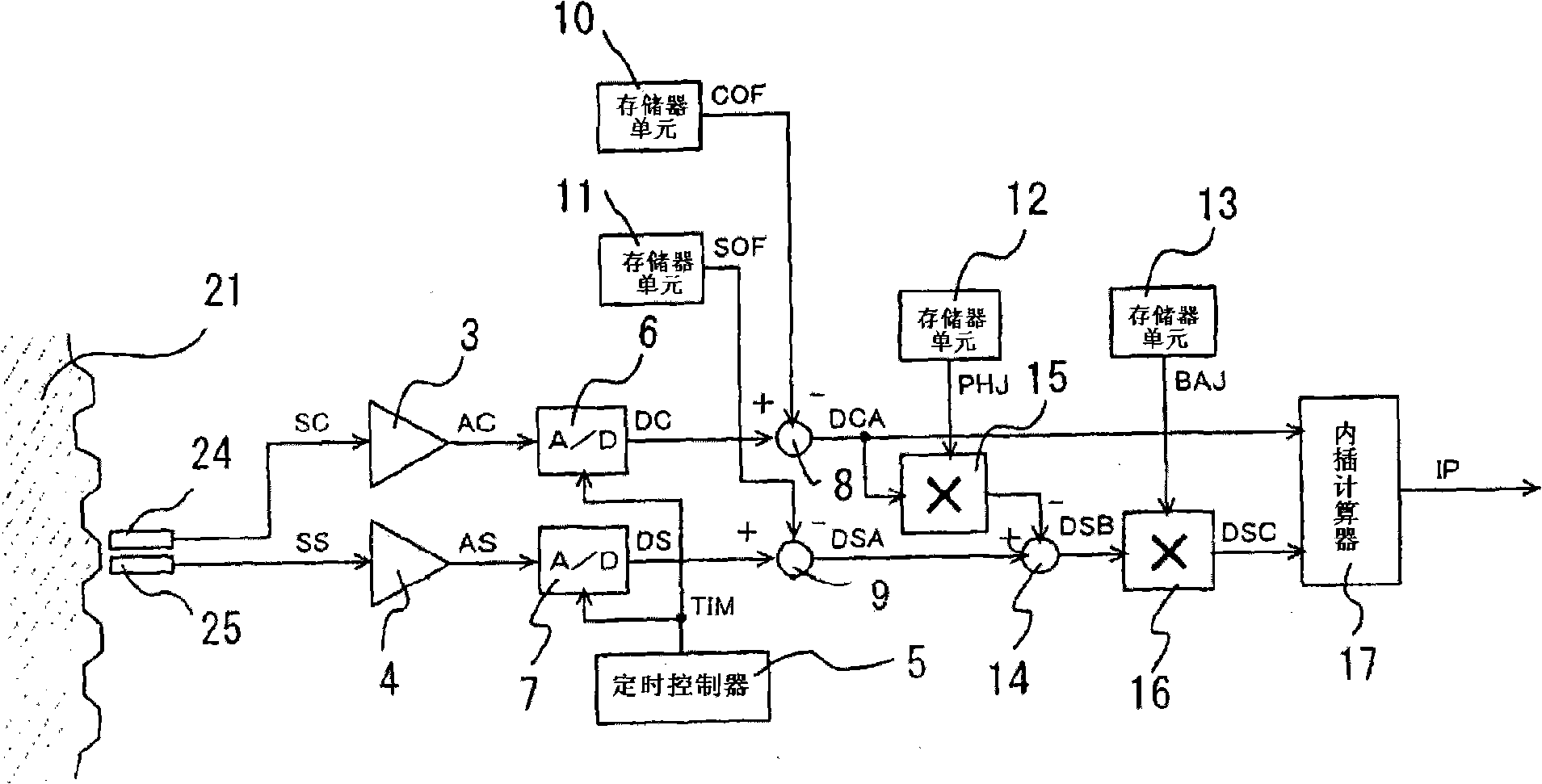

[0014] figure 2 is a diagram showing the basic structure of a position detector. image 3 to show figure 2 A block diagram of the interpolation operation of the signal processing circuit 29 in . exist figure 2 Among them, the rotor 21 fixed on the rotating shaft 1 is composed of a magnetic member having 36 depressions and protrusions on its outer circumference at a pitch of wavelength λ=10 degrees in one rotation. On one of the 36 protrusions of the rotor 21, a protrusion 22 made of a magnetic member for indicating the start is attached. The printed circuit board 23 mounted on the non-rotating portion of the measurement target (motor) is located on the side adjacent to the outer surface of the rotor 21 . Formed on the printed circuit board 23 are two kinds of detection coils 24 and 25 forming a sinusoidal conductive pattern, and a detection coil 26 for detecting a prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com