Meridian tyre steel wire cord defect permanent magnetism excitation magnetic distortion detection probe and method

A technology of steel cords and detection probes, applied in the direction of material magnetic variables, etc., can solve the problems of high equipment cost and maintenance cost, X-ray hazard, etc., and achieve the effects of solving high equipment cost and maintenance cost, convenient detection and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

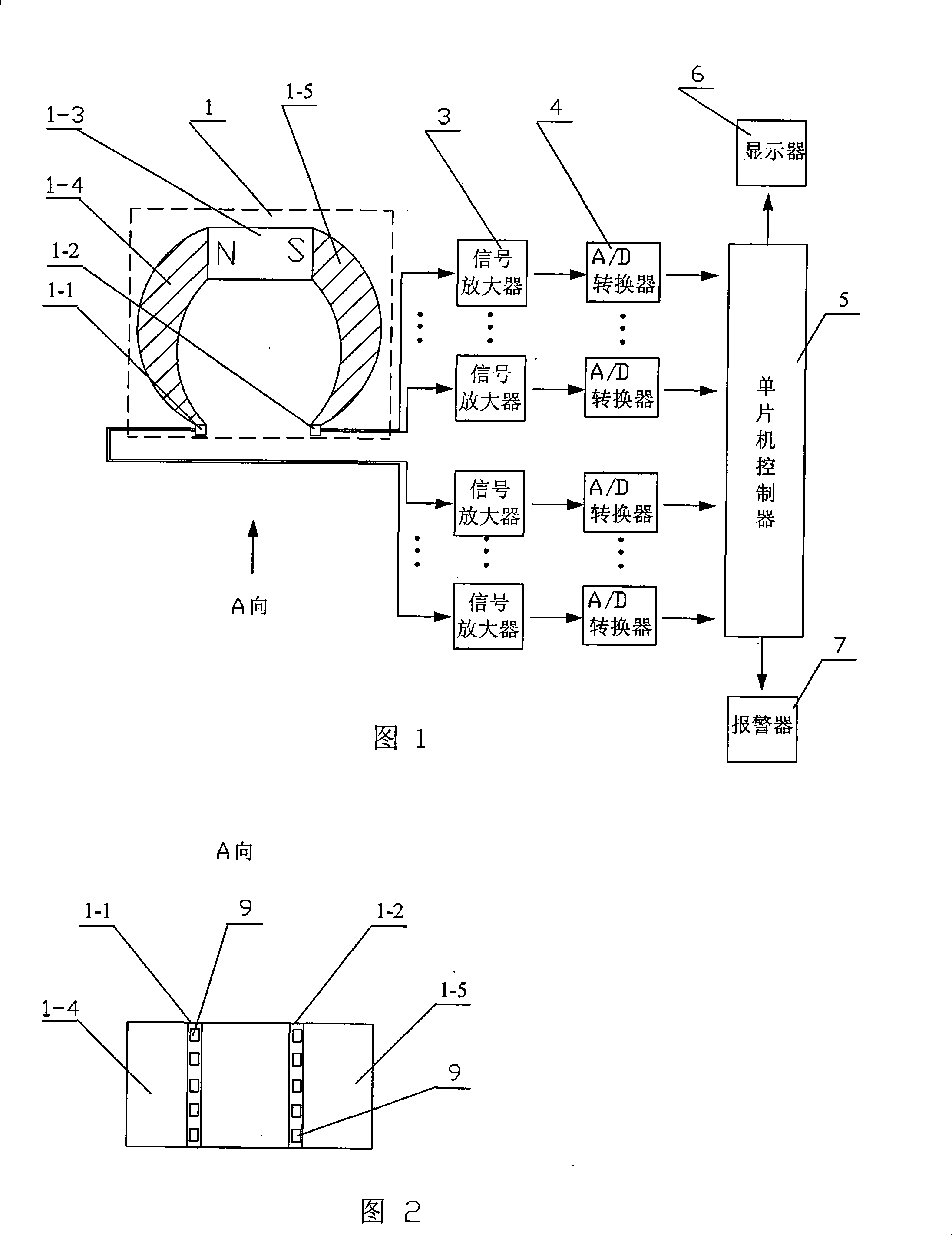

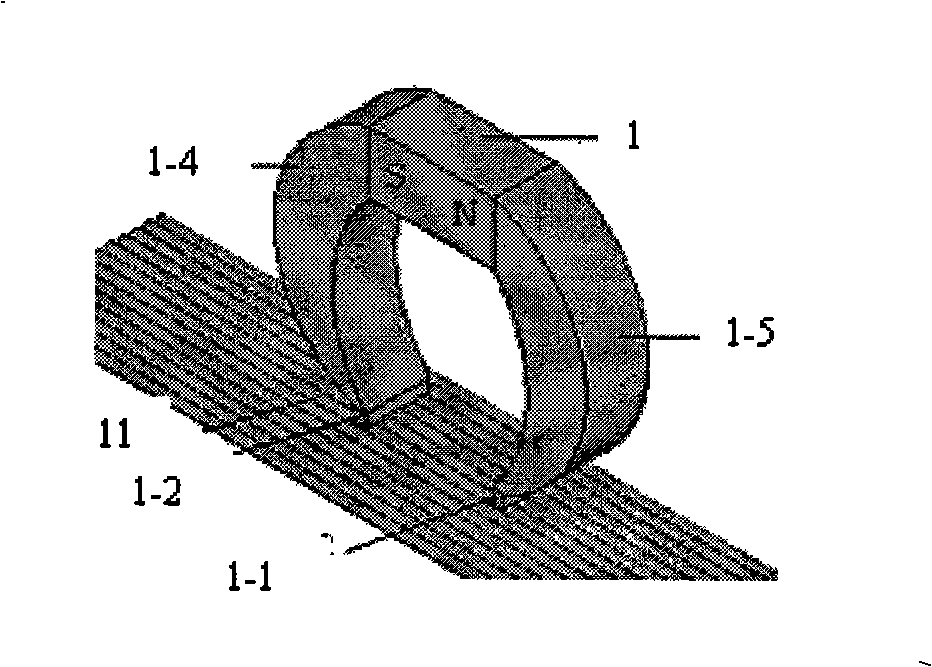

[0008] Specific embodiment one: this embodiment is specifically described in conjunction with Fig. 1 and Fig. 2, the permanent magnetic excitation magnetic field distortion detection probe of radial tire steel cord defect of this embodiment, it is made up of detection probe 1 and measurement and control circuit; Described detection Probe 1 is composed of N pole Hall element detection array 1-1, S pole Hall element detection array 1-2, permanent magnet 1-3, N pole yoke 1-4 and S pole yoke 1-5; N pole The Hall element detection array 1-1 is composed of five Hall elements 9 equidistantly arranged in a row, and the S pole Hall element detection array 1-2 is composed of five Hall elements 9 equidistantly arranged in a row. The measurement and control circuit includes ten signal amplifiers 3, ten A / D converters 4, single-chip controller 5 and display 6; N pole yokes 1-4, permanent magnets 1-3 and S pole yokes 1-5 in sequence Connected and form a "jaw" shape, the N-pole Hall element ...

specific Embodiment approach 2

[0010] Specific embodiment two: illustrate this embodiment in conjunction with Fig. 1, the difference between this embodiment and specific embodiment one is: it also comprises annunciator 7, and the signal input end of annunciator 7 connects another output end of single-chip microcomputer controller 5 . The defect of the tire steel cord is not only displayed on the display, but also given by the alarm, so that the operator can see it at a glance.

specific Embodiment approach 3

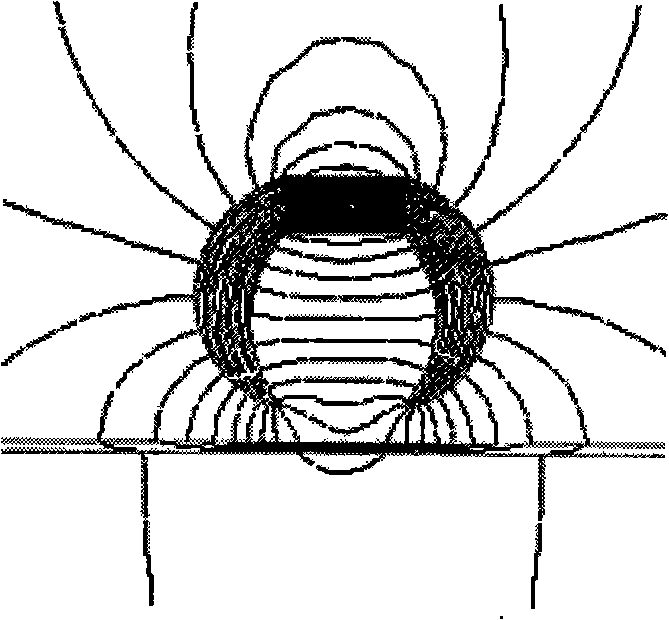

[0011] Specific embodiment three: the permanent magnet excitation magnetic field distortion detection method of the radial tire steel cord defect of the present embodiment comprises the following steps: 1. Carry out calibration: the calibration process passes through the N pole Hall element detection array 1-1 of the detection probe 1 and The S-pole Hall element detection array 1-2 scans the surface of the defect-free steel cord radial tire in the specified order, and the scanning direction is along the N-pole Hall element detection array 1-1 and the S-pole Hall element detection array The connection direction of 1-2 detects the magnetic field distribution of each position of the radial tire steel cord without defect, and records the data corresponding to the magnetic field distribution of each position through the memory of the single-chip controller 5; 2. Use the detection probe 1 The N pole Hall element detection array 1-1 and the S pole Hall element detection array 1-2 scan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com