A transparent product and its making technology

A process technology and product technology, applied in the field of light-transmitting products, can solve the problems of poor processing precision, high processing cost, and low yield rate, and achieve the effect of low processing cost, high yield rate, and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

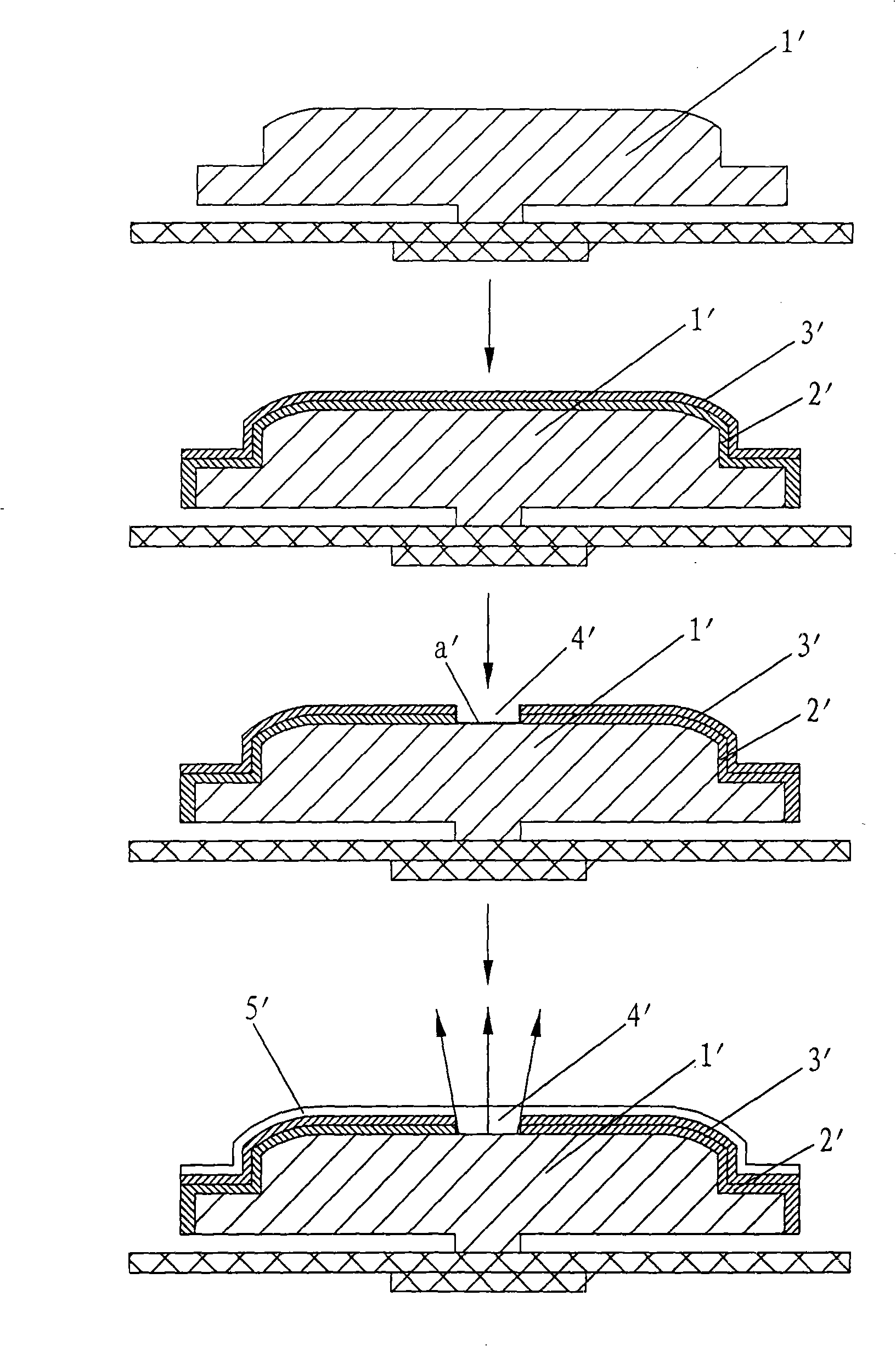

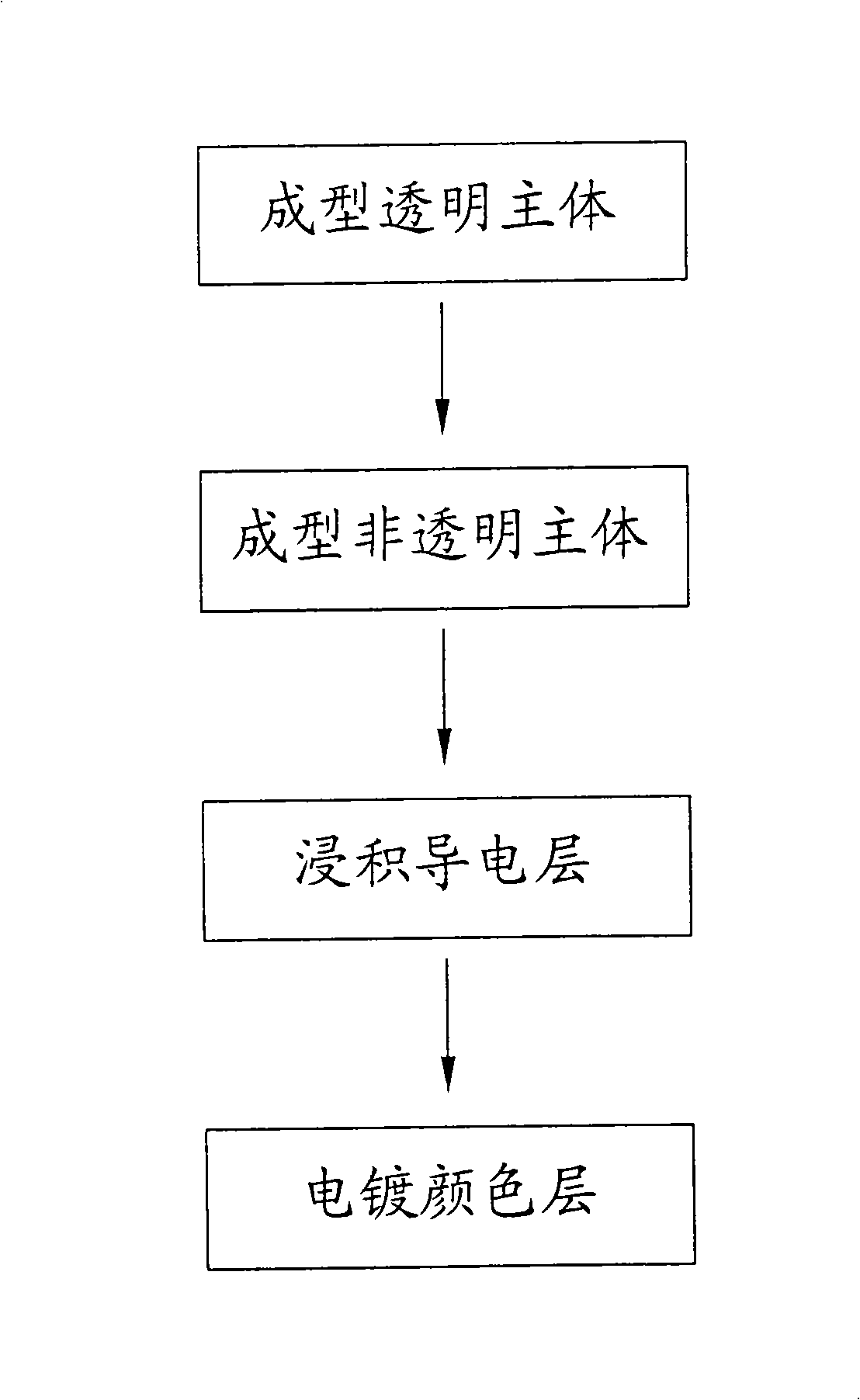

Method used

Image

Examples

Embodiment Construction

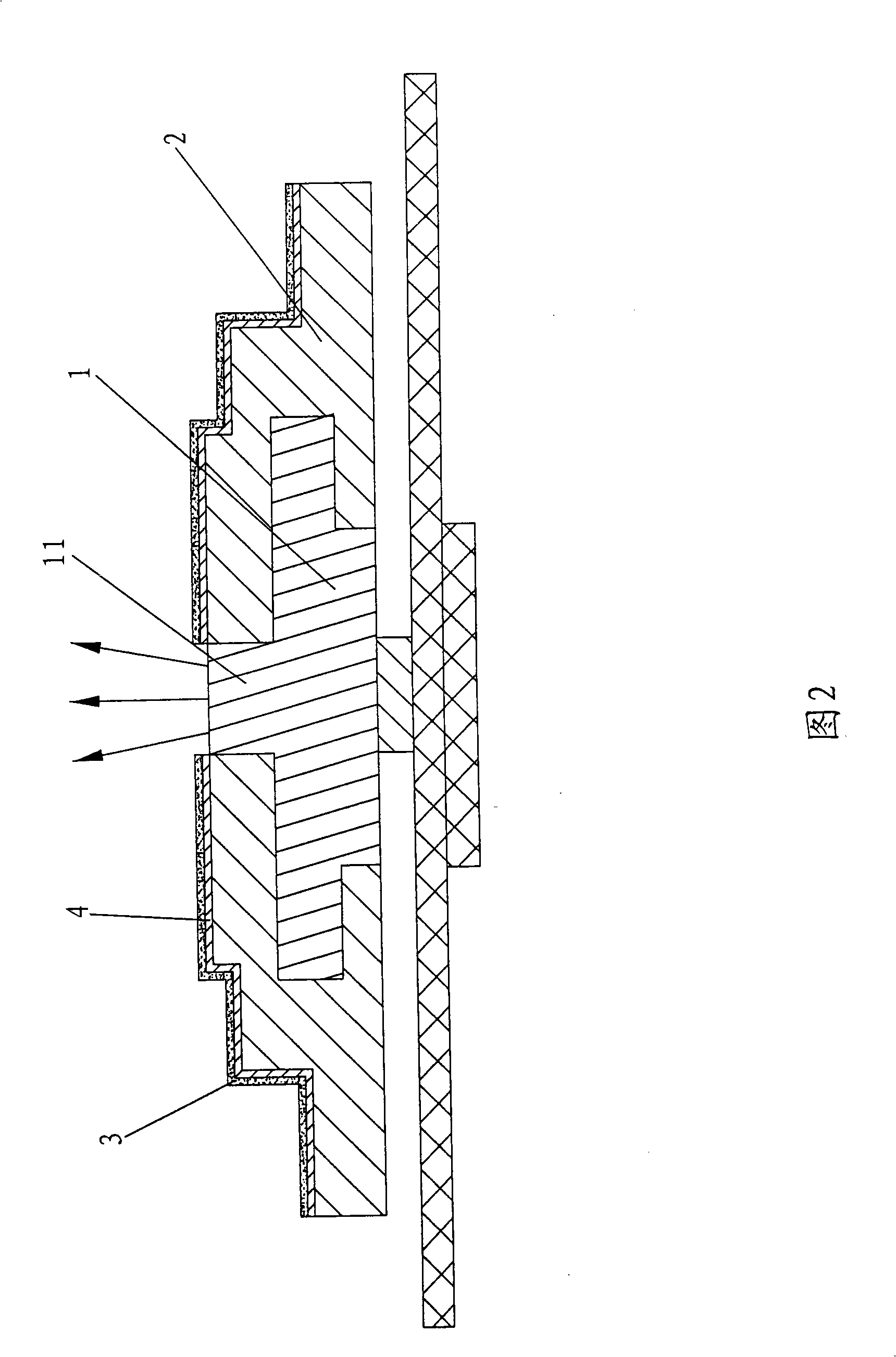

[0029] As shown in FIG. 2 , the light-transmitting product of the present invention mainly includes a light-transmitting body 1 and a non-light-transmitting body 2 . in:

[0030] The light-transmitting body 1 is provided with an embossed portion 11 , and the embossed portion 11 is arranged in numbers, letters or various patterns according to different functions.

[0031] The non-transparent main body 2 is molded in the recessed position on the outer surface of the transparent main body 1 , so that the top surface of the embossed portion 11 of the transparent main body 1 is just flush with the top surface of the non-transparent main body 2 after molding.

[0032] In addition, a layer of color layer 3 can be electroplated on the non-translucent main body 2 on the outer surface of the product, thereby increasing the color of the product. For the convenience of electroplating, a conductive layer 4 must first be provided on the surface of the non-transparent main body 2. The color...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com