Apparatus for producing pills

The technology of a dripping pill machine and dripper is applied in the direction of making medicines into special physical or taking forms, which can solve the problems of affecting the weight of pills, inconvenient operation, difficult temperature control, etc., and achieve small temperature deviation and convenient operation , good molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

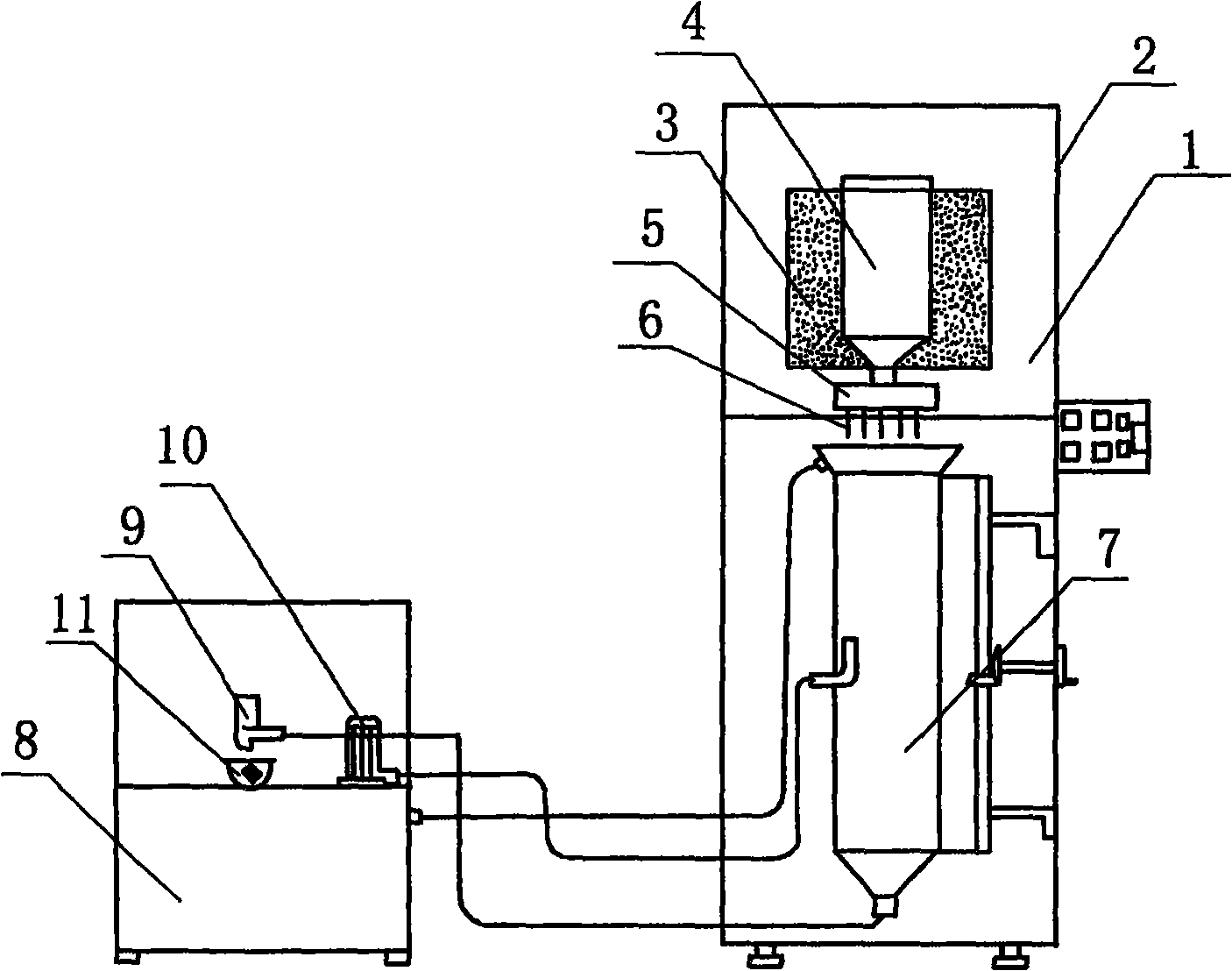

[0008] exist figure 1 Among them, the present invention is a kind of dripping pill machine, which includes a dripping pill machine main body 1 and a cooling medium circulation device. The dripping pill machine main body 1 includes a housing 2, and an oil tank 3 is arranged in the upper part of the housing 2. The oil tank 3 There is a material tank 4 inside, a drip tank 5 is provided at the bottom of the material tank 4, a ball valve is arranged between the drip tank 5 and the material tank 4, the drip tank 5 and the material tank 4 are separated by a ball valve, and the bottom of the drip tank 5 is provided with a ball valve. There is a dripper 6, the thickness of the pipe wall of the dripper 6 outlet is less than 0.3mm, and a cooling barrel 7 is provided at the lower part of the housing 2, and the cooling barrel 7 corresponds to the dripper 6, and the cooling medium circulation device is provided with The refrigeration cycle tank 8 is connected with the cooling barrel 7 at th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com