Electrolytic deposition metal peeling method and electrolytic deposition metal transmission method

A technology of electrolytic deposition and conveying device, which is applied in the electrolysis process, electrolysis components, photographic technology, etc., can solve the problems of dislocation of the stop position of the conveyor, obstruction of smooth pressure processing and corrugation processing, and increase of work burden, so as to prevent the occurrence of dislocation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

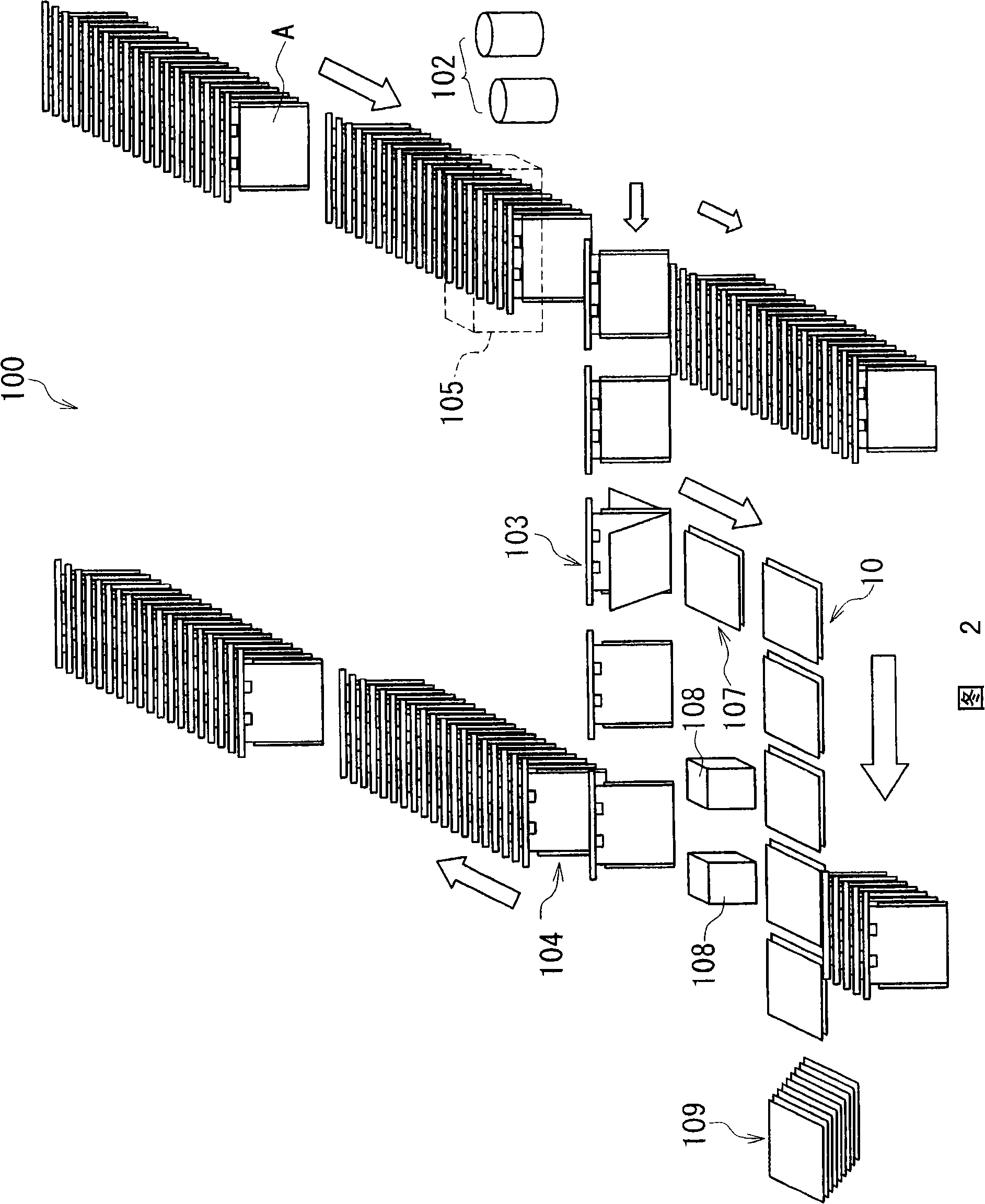

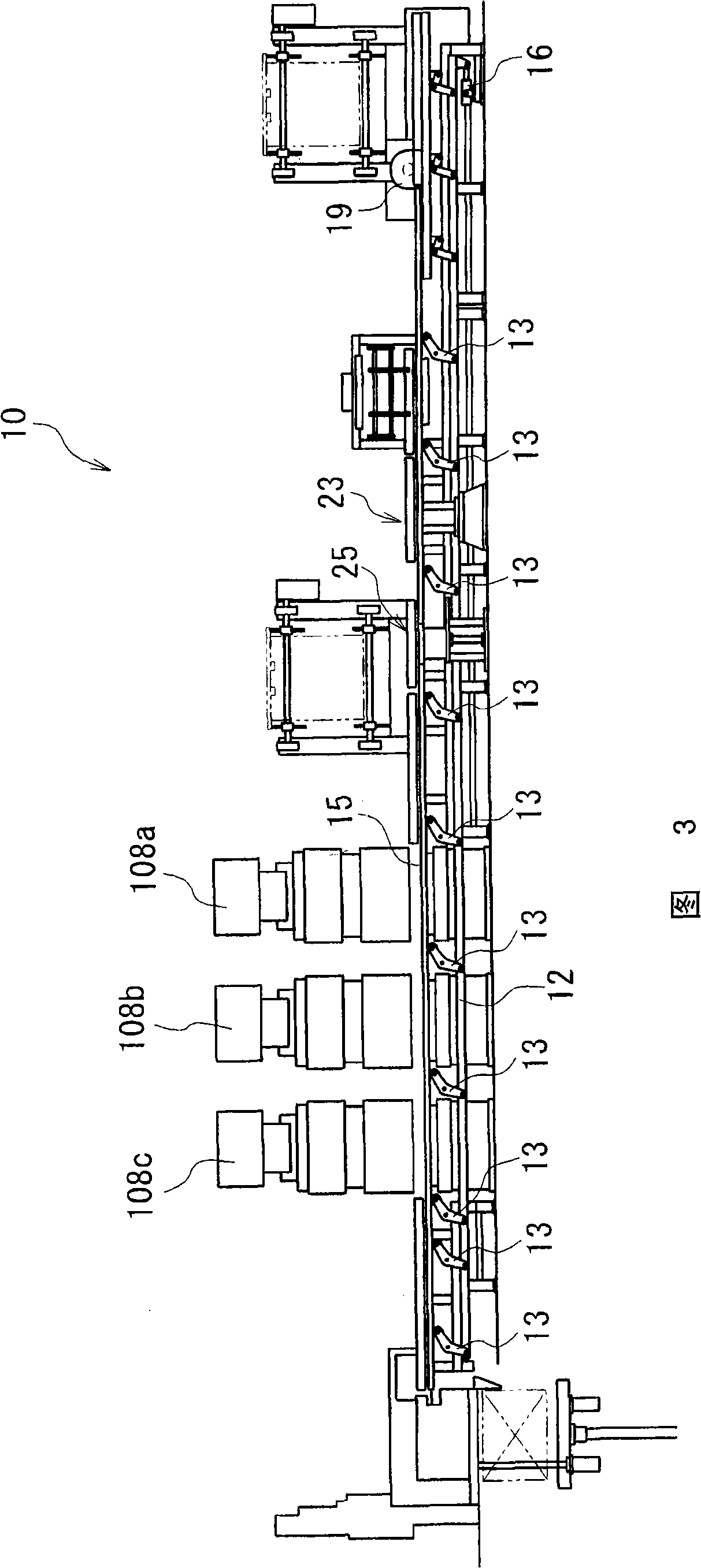

[0042] Next, the electrodeposited metal conveying device and the electrodeposited metal conveying method involved in the present invention will be described in detail with reference to the accompanying drawings. Fig. 2 is a schematic diagram of an embodiment of the electrolytic deposition metal recovery system, Fig. 3 is a side view of an embodiment of the electrolytic deposition metal conveying device involved in the present invention, and Fig. 4 is the electrolytic deposition metal conveying device of Fig. 3 top view of the device, Figure 5 It is a diagram showing the situation during transportation.

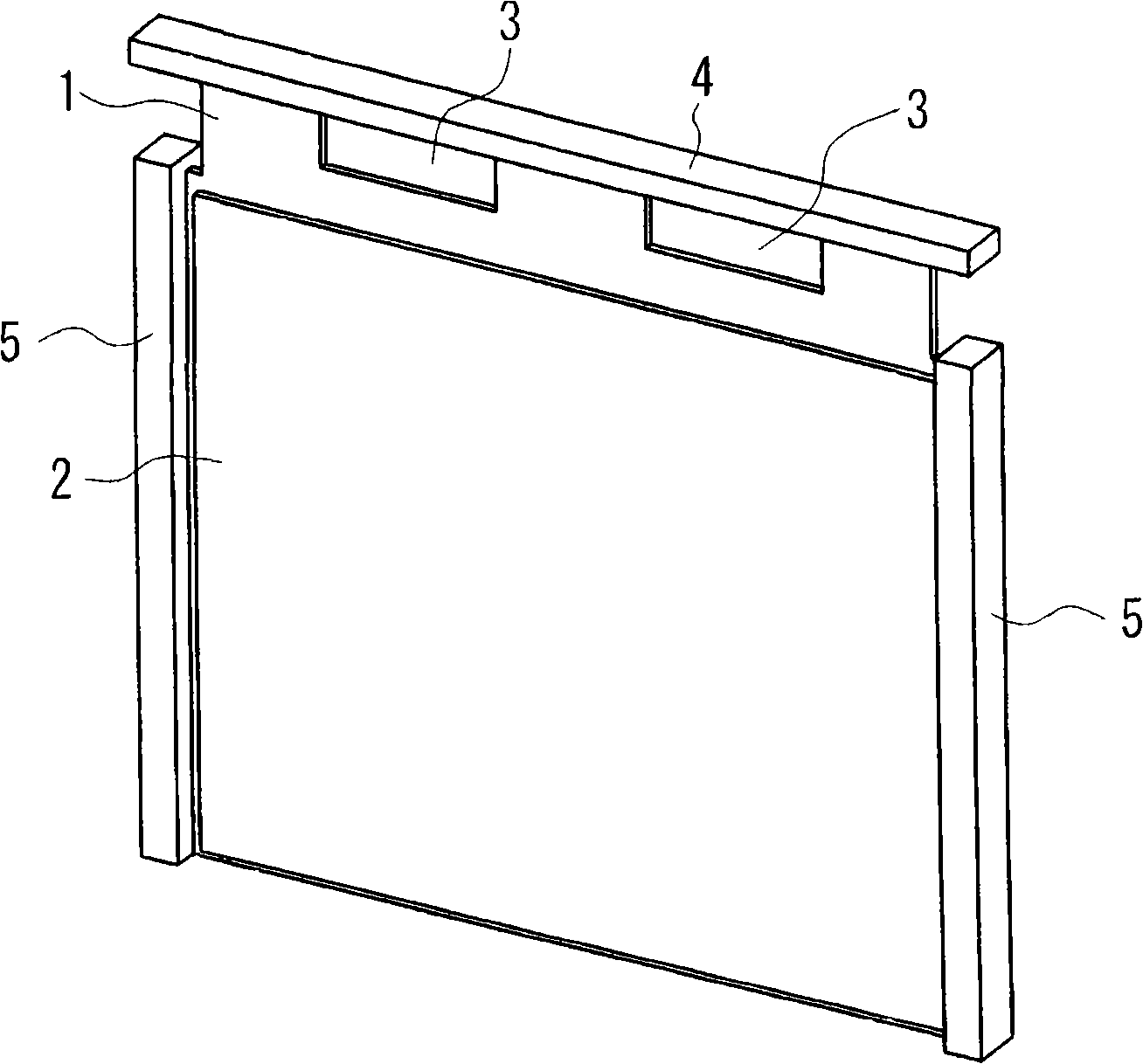

[0043] First, an outline of a system for recovering electrolytic copper as an electrodeposited metal will be described with reference to FIG. 2 . The system 100 for recovering electrolytic copper includes: figure 1 The cathode plate 1 made of stainless steel with electrolytic copper 2 precipitated on the surface shown (hereinafter referred to as "laminated plate A") is fed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com