Reciprocating compressor stepless gas amount regulating system used for explosive gas area

A technology of air volume adjustment and compressor, which is applied in the direction of liquid variable capacity machinery, mechanical equipment, machine/engine, etc., and can solve the problem that stepless adjustment cannot be realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with drawings and embodiments.

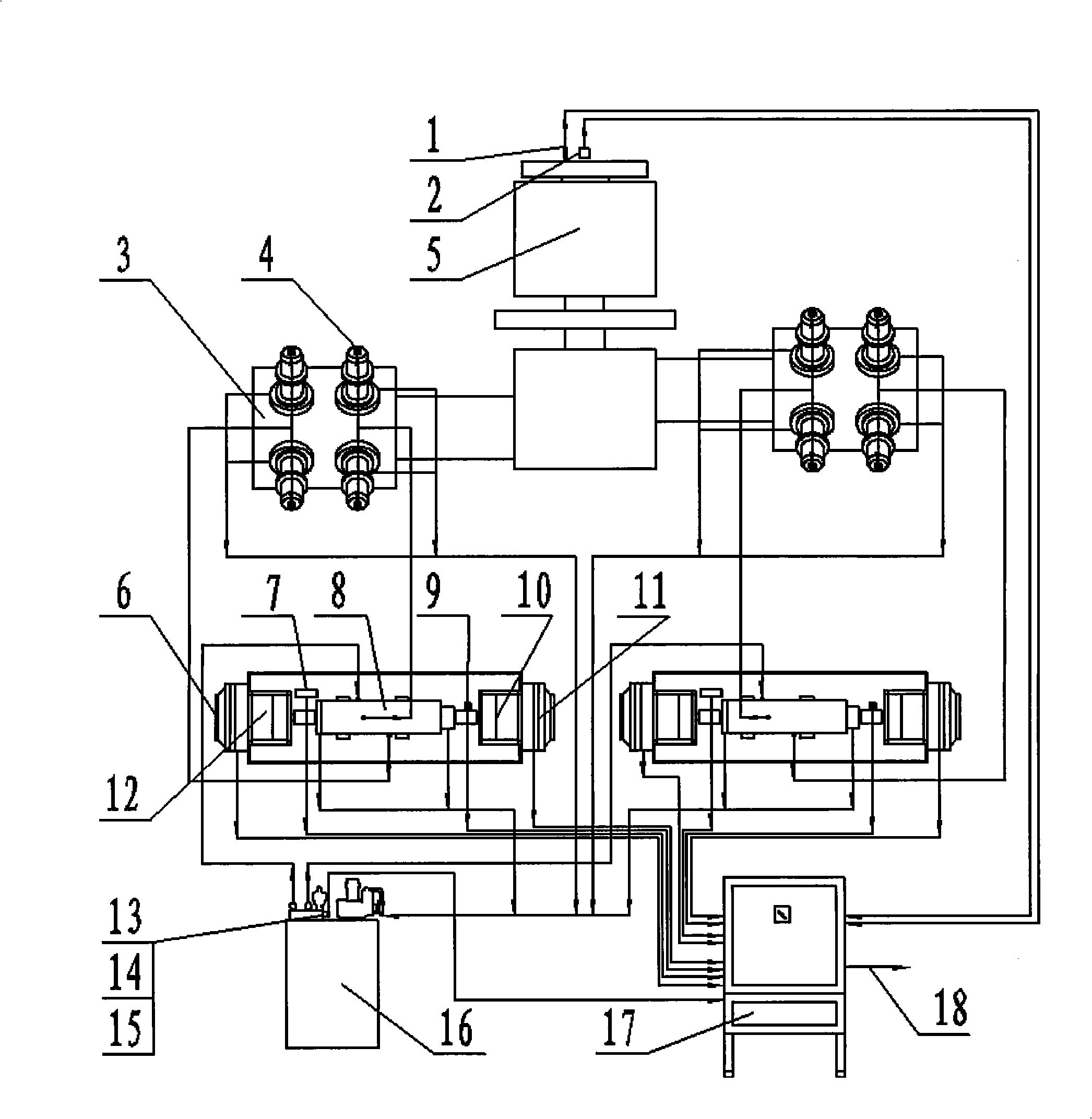

[0021] Such as figure 2 As shown, the present invention includes an explosion-proof hydraulic oil station 16, two or more hydraulic distributors 8 with the same structure, an unloader 4 mounted on two or more compressor cylinders, an explosion-proof control box 17, a piston dead center sensor 1 and a crankshaft code Device 2; one end of each hydraulic distributor 8 is equipped with a synchronous servo motor 11 connected to the synchronous servo motor reduction box 10, and the other end of the hydraulic distributor 8 is equipped with an adjustment servo motor 6 connected to the adjustment servo motor reduction box 12, The high-pressure hydraulic oil output by the explosion-proof hydraulic oil station 16 enters the oil inlet hole of the hydraulic distributor 8, and then flows out from the two oil outlet holes of the hydraulic distributor 8, and is respectively connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com