An intensive DC ice-melting system for 500kv substation with svg function

A technology of DC ice melting and substation, which is applied in the installation of flexible AC power transmission system, electrical components, cables, etc. It can solve the problems of high temperature, need for deionization treatment, affect device reliability, and heavy maintenance workload, etc., to meet the requirements of High reliability and dynamic reactive power compensation requirements, optimization of dynamic reactive power and static reactive power coordination, and the effect of reducing device volume and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

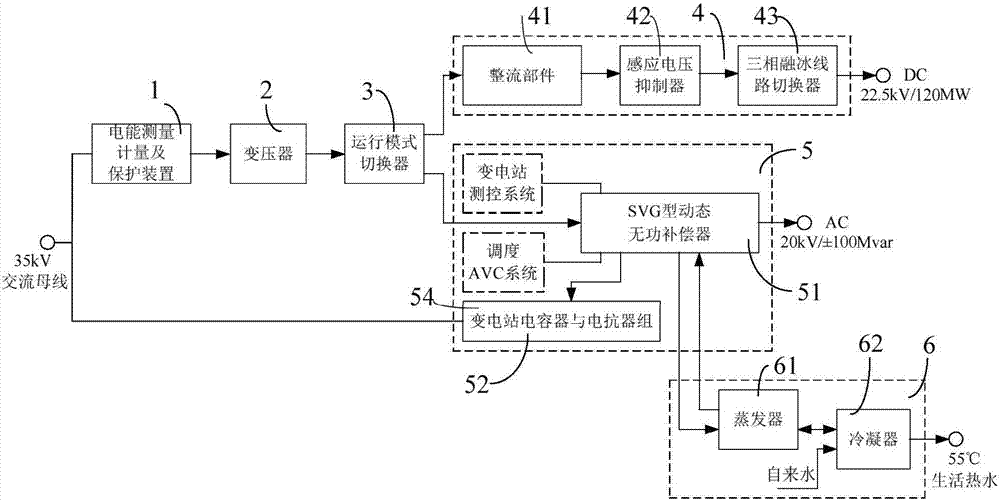

[0021] Such as figure 1 As shown, the 500kV substation intensive DC ice-melting system with SVG function in this embodiment includes an electric energy measurement and protection device 1, a transformer 2, an operation mode switcher 3, a DC ice-melting unit 4 and a dynamic reactive power compensation unit 5, The primary side of the transformer 2 is connected to the 35kV AC bus of the substation through the electric energy measurement and protection device 1 , and the secondary side of the transformer 2 is connected to the DC deicing unit 4 and the dynamic reactive power compensation unit 5 through the operation mode switch 3 respectively. In this embodiment, the output terminal of the transformer 2 after stepping down the 35kV high voltage is connected to the input terminal of the operation mode switcher 3, and the output terminal of the operation mode switcher 3 is respectively connected to the input terminals of the DC ice melting unit 4 and the dynamic reactive power compens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com