Stepped control type flux valve

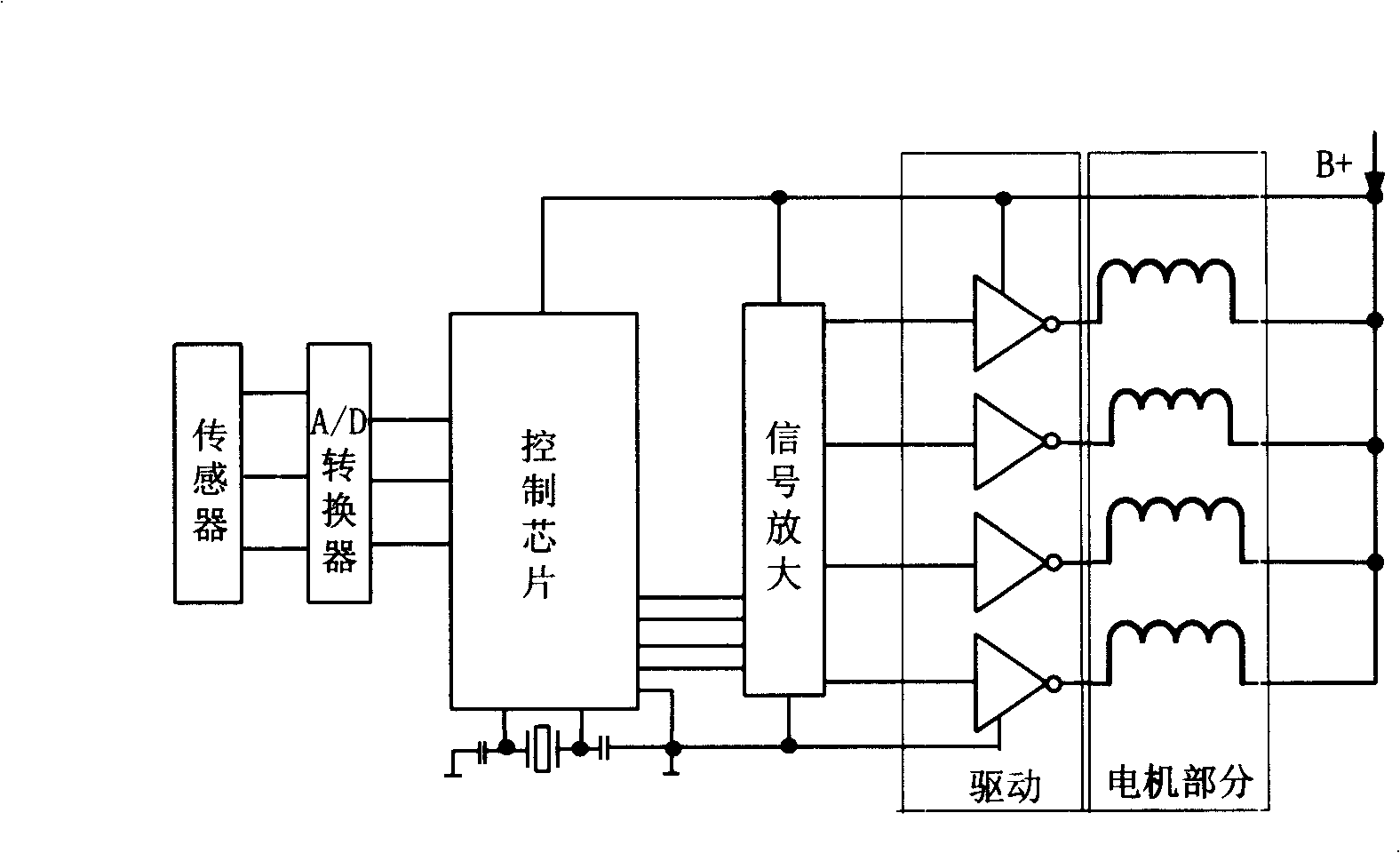

A step control, flow valve technology, applied in the direction of using electric device flow control, lift valve, valve details, etc., can solve problems such as unstable system operation, and achieve the effect of small valve body volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

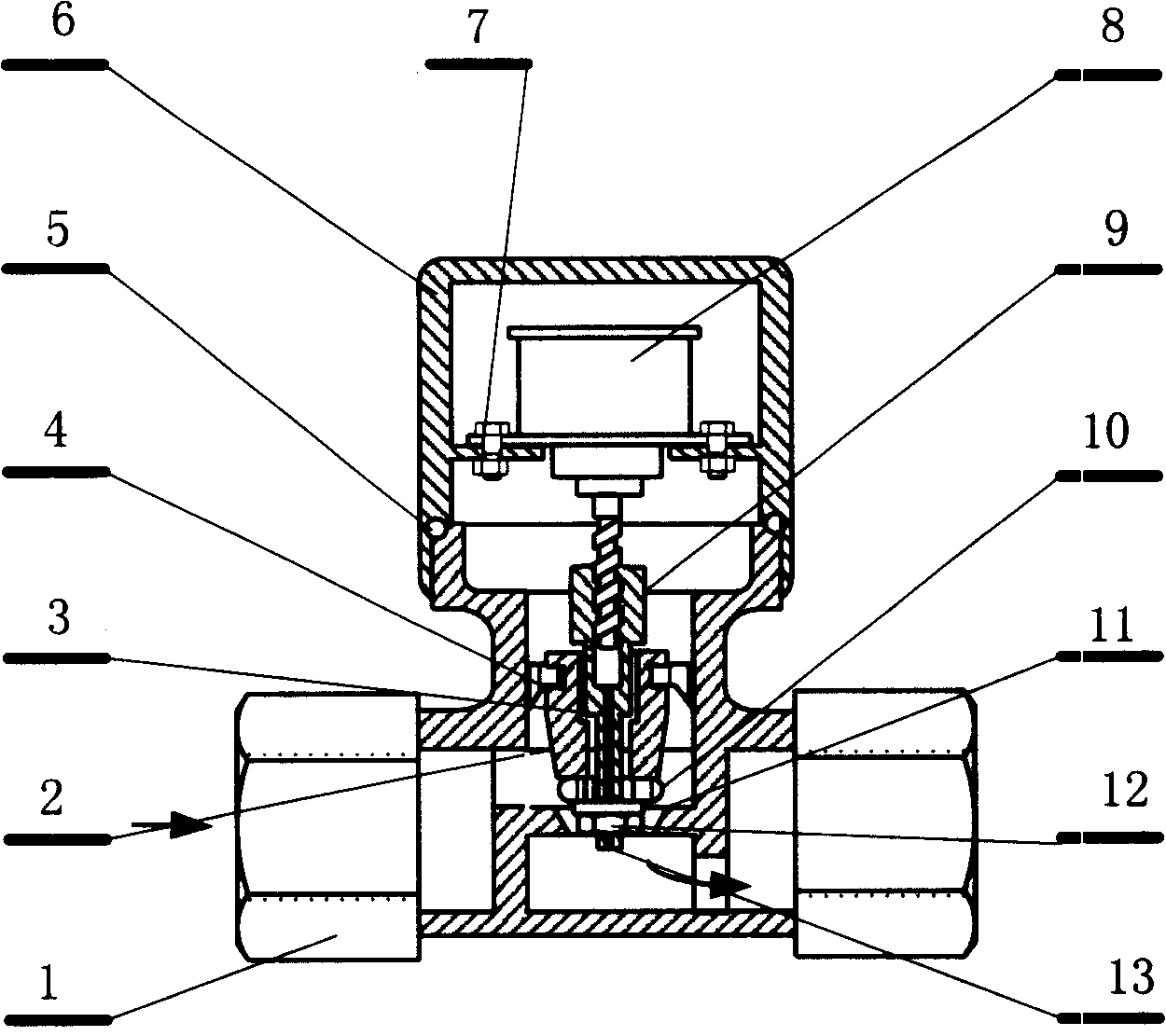

[0009] figure 2 It is a straight-through stepping valve structure. The valve body (1) can be made of stainless steel or copper. The interfaces at both ends can be designed according to the requirements of the equipment. For example, it can be processed into outer wire or inner wire, or it can be processed into live wire connection method. There is a water outlet (11) in the valve body (1), and the upper part of the valve body (1) is connected with the sealing cover (6) through threads and the valve cover sealing ring (5), and a stepping motor is installed in the sealing cover (6) (8), the output shaft of the stepper motor (8) is connected with the linkage rod (9) through threads, the transmission rod (9) is installed in the inner cavity of the piston (2), and is slidingly connected with the inner cavity of the piston (2), and the transmission A sealing ring (10) is installed on the lower part of the rod (9), and the sealing ring (10) is fixed on the lower part of the transmi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap