Softening valve with mixed flow function

A technology for softening valves and functions, applied in valve details, multi-way valves, valve devices, etc., can solve the problems of increased processing costs, increased volume, and the inability to set mixing stations, etc., to reduce processing costs, The valve body is small in size and compact in structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The principles and features of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that the examples given are only used to explain the present invention, and do not constitute a specific limitation to the patent protection scope of the present invention.

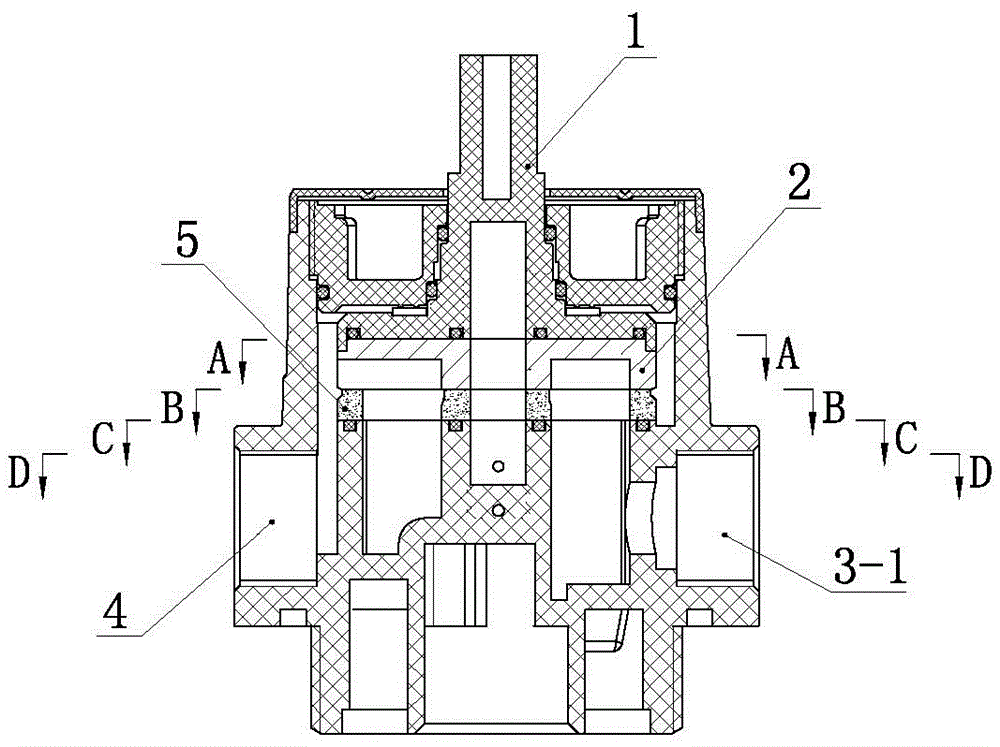

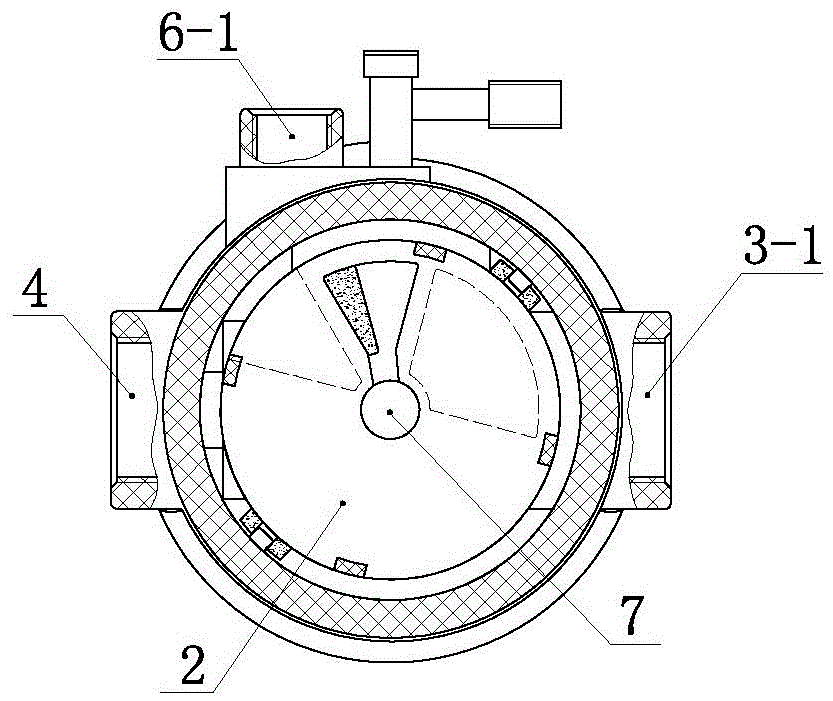

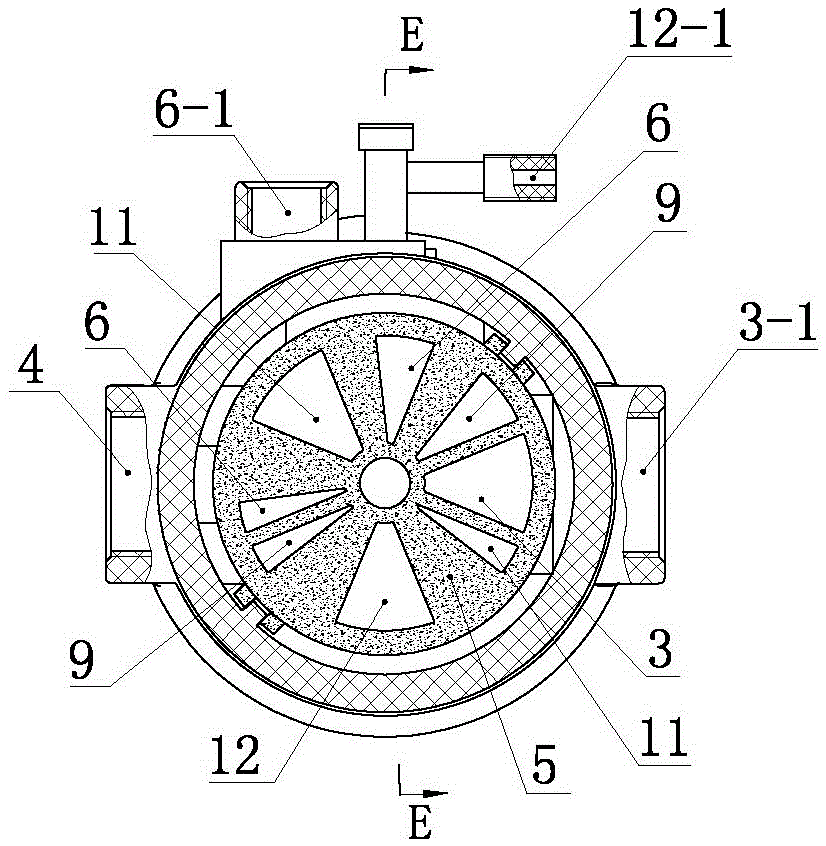

[0030] This softening valve with mixing function (Fig. 1 -picture 20 shown), it is a valve seat with a set of face-to-face seals in the core cavity of the valve body 5 and spool 2 ; When treated softened water is required with raw water mixing ratio, Perform softening mixed flow station when (Fig. 14 ,picture 15 shown), by turning the lever 1 drive the spool at its lower end 2 Rotate so that the water hole on the first end face of the lower end face of the spool 14 Indexing and the first station water hole on the end face of the valve seat 11 Connected, the second end face water hole on the lower end face of the s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap