Production scheduling system and method using genetic algorithm based on elite solution pool

A genetic algorithm and production scheduling technology, applied in the field of production scheduling system, can solve problems such as low efficiency, and achieve the effect of improving efficiency, easy implementation, and fast operation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

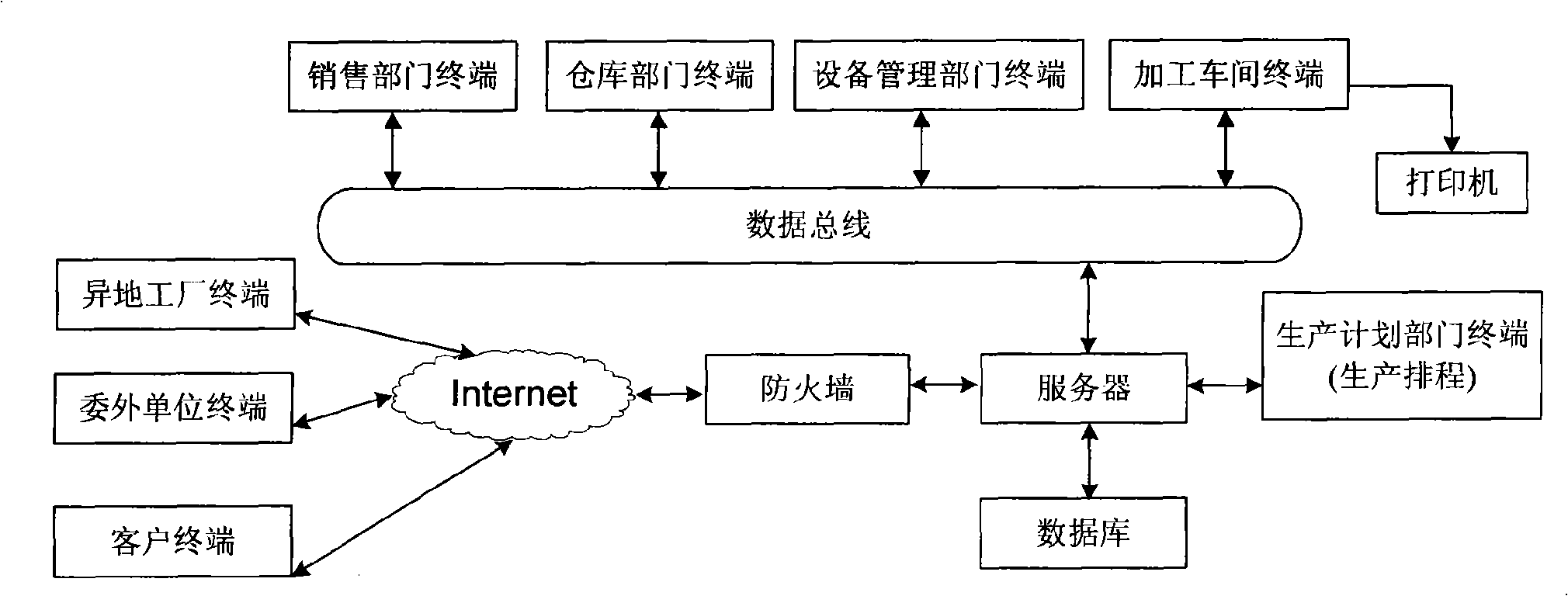

[0052] The present invention adopts the hardware topology of the client / server such as figure 1 As shown: the whole system is centered on the server, and the server is connected to the database, the terminal of the production planning department and various information terminals (the terminal is the client), including: the terminal of the sales department (collecting order data), the terminal of the warehouse department (collecting material information), Equipment management department terminal (to collect equipment information) and processing workshop terminal. Among them, the processing workshop can be equipped with a printer to print the final scheduling plan for easy execution. In addition, the server also connects with remote factory terminals, outsourcing unit terminals and customer terminals through the Internet to exchange order information and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com