Pet pads and manufacturing method thereof

A manufacturing method and pet pad technology, applied in the pet pad field, can solve problems such as leakage of pet pads, and achieve the effects of saving production costs, low energy consumption, and high output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

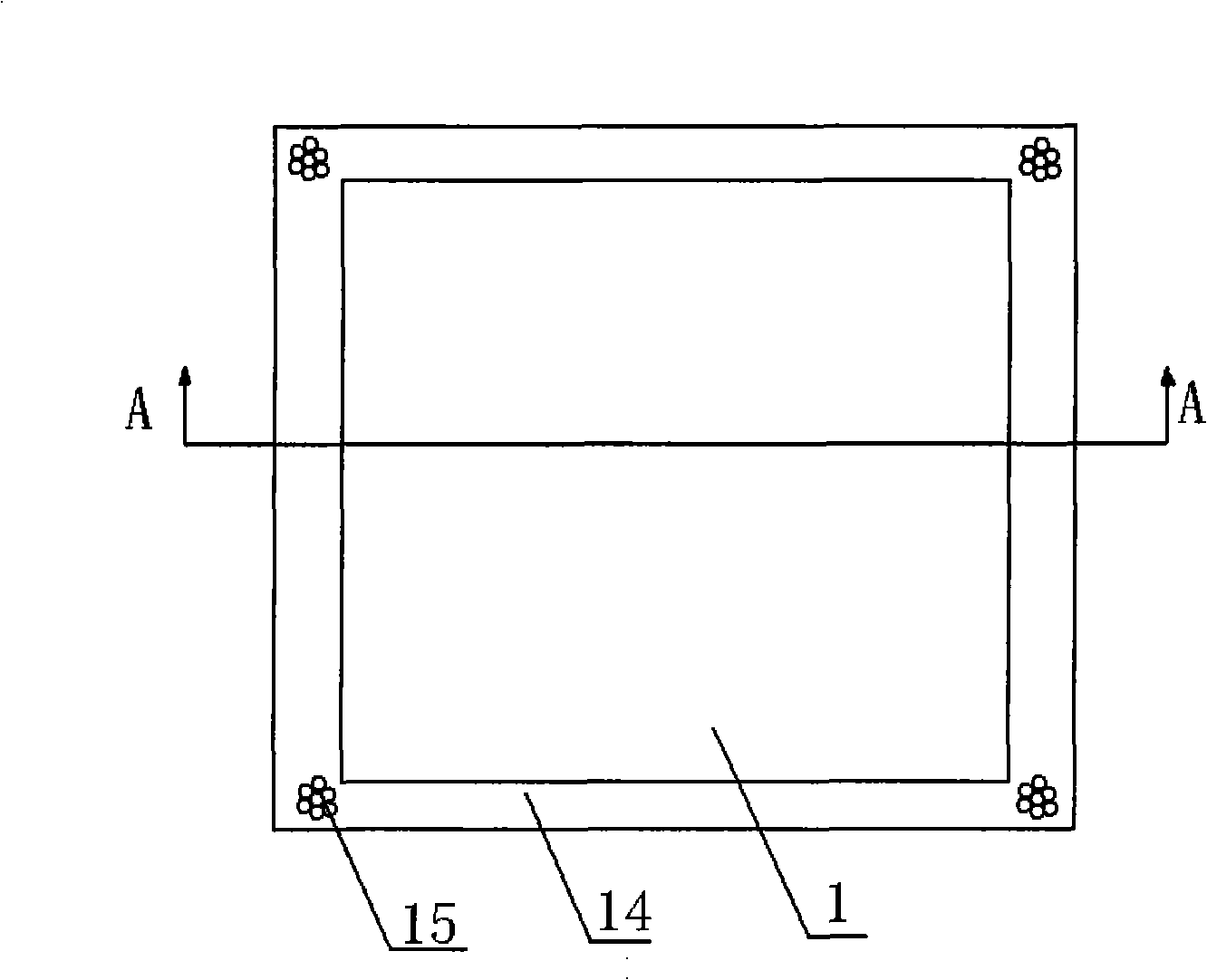

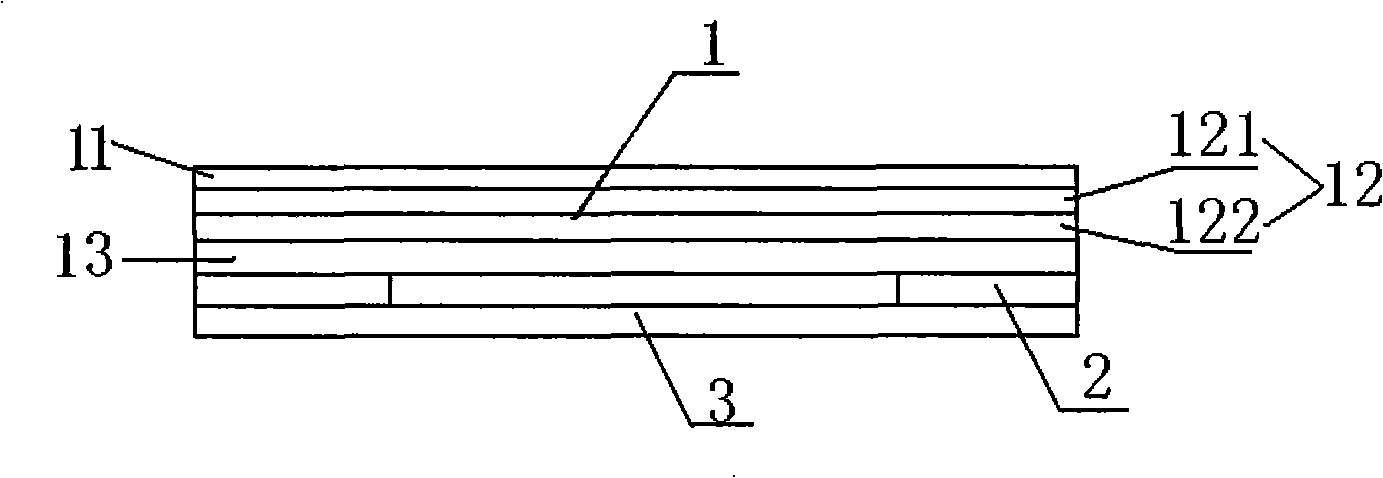

[0034] The selected non-woven fabric has a weight of 10g / m 2 , the weight of the polymer water-absorbing layer is 20g / m 2 , the weight of toilet paper is 6g / m 2 , the weight of the waterproof film is 1g / m 2 , first stack the non-woven fabric as the surface layer, the polymer water-absorbing layer as the middle layer, toilet paper, and the water-absorbing film as the bottom layer. After the superimposition, heat pressing with an electric heating roller. The temperature of the hot pressing is 50°C , the speed is 60 pieces / min. After hot pressing, spray glue or paste double-sided tape on the lower surface of the bottom layer, then paste non-sticky paper, and finally cut, that is, the finished product and package.

Embodiment 2

[0036] The selected non-woven fabric has a weight of 1000g / m 2 , the weight of the polymer water-absorbing layer is 1000g / m 2 , the weight of toilet paper is 60g / m 2 , the weight of the waterproof film is 60g / m 2 , first stack the non-woven fabric as the surface layer, the polymer water-absorbing layer as the middle layer, toilet paper, and the water-absorbing film as the bottom layer. After the superposition, heat pressing with an electric heating roller. The temperature of the hot pressing is 260 ° C. , the speed is 500 pieces / min. After hot pressing, spray glue or paste double-sided tape on the lower surface of the bottom layer, then paste non-sticky paper, and finally cut, that is, the finished product and package.

Embodiment 3

[0038] The selected non-woven fabric has a weight of 500g / m 2 , the weight of the polymer water-absorbing layer is 500g / m 2 , the weight of toilet paper is 30g / m 2 , the weight of the waterproof film is 30g / m 2 Firstly, superimpose the non-woven fabric as the surface layer, the polymer water-absorbing layer and toilet paper as the middle layer, and the water-absorbing film as the bottom layer. After the superposition, heat pressing with an electric heating roller. The temperature of the heat pressing is 160 ° C. , the speed is 260 pieces / min. After hot pressing, spray glue or paste double-sided tape on the lower surface of the bottom layer, then paste non-sticky paper, and finally cut, that is, the finished product and package.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com