Bisphenol A type sulfonated polysulfone copolymer and synthetic method thereof

A technology of sulfonated polysulfone and a synthesis method, applied in the field of polysulfone copolymer and its synthesis, can solve the problems of easy occurrence of side reactions, difficult control of sulfonation degree of synthetic polysulfone copolymer, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

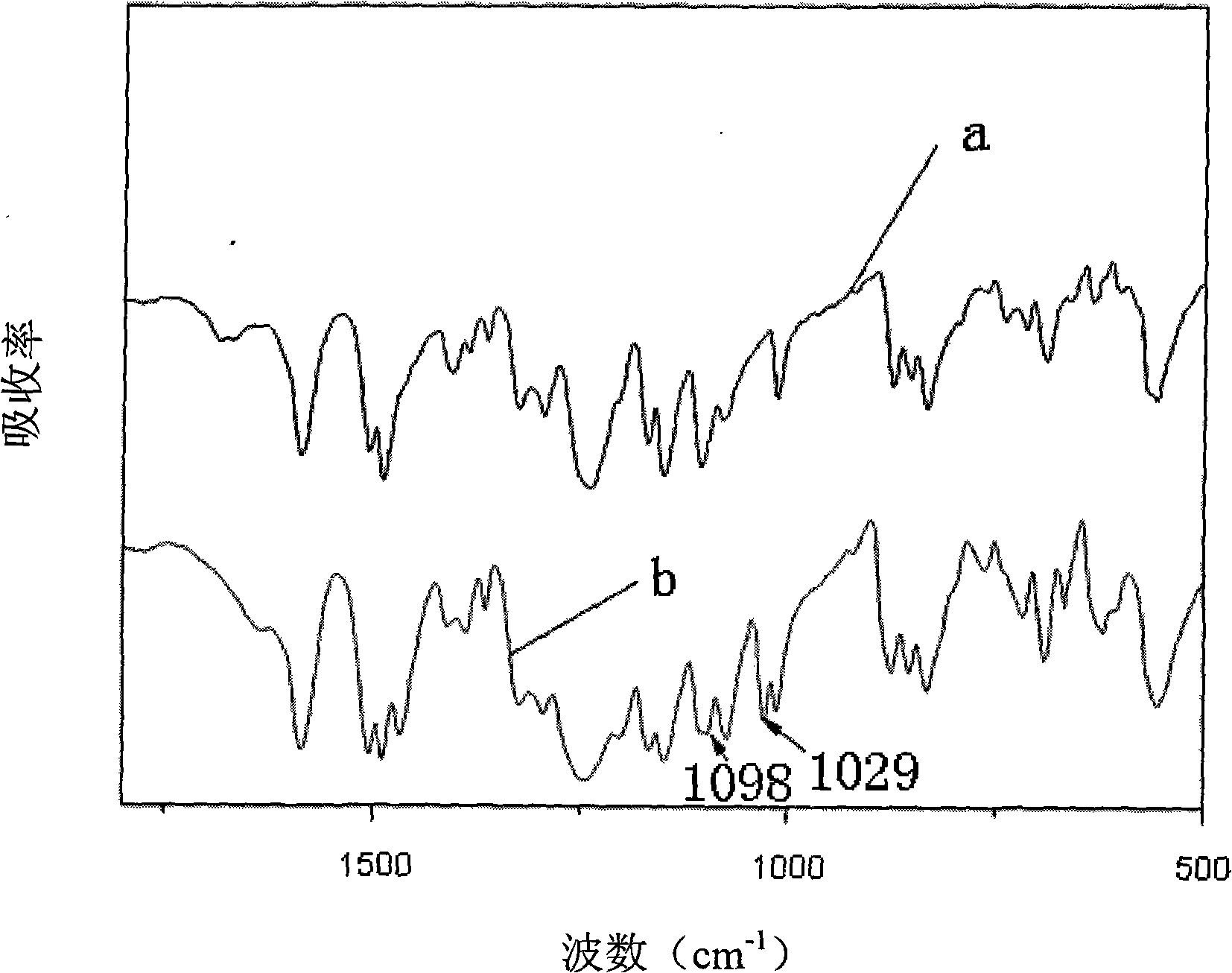

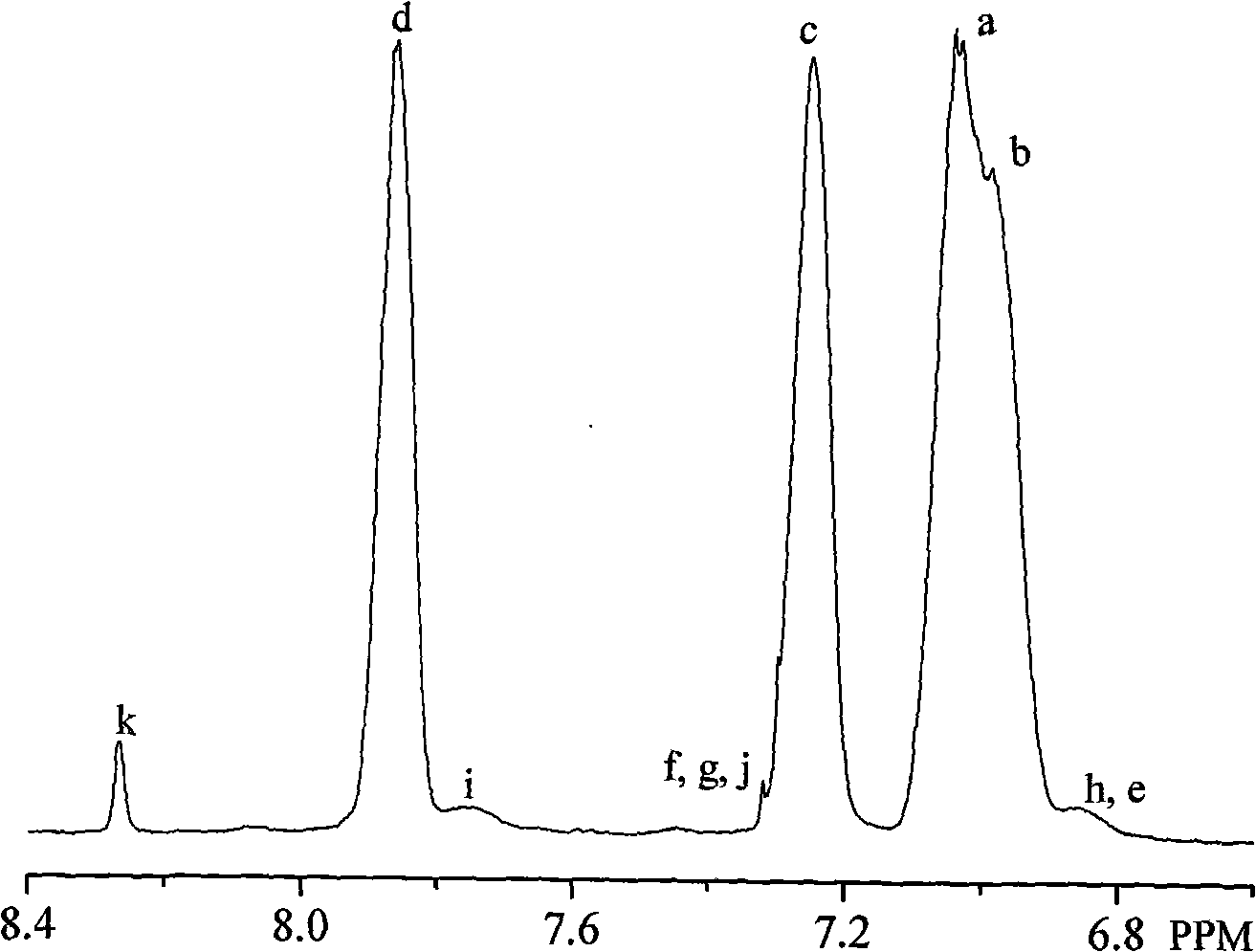

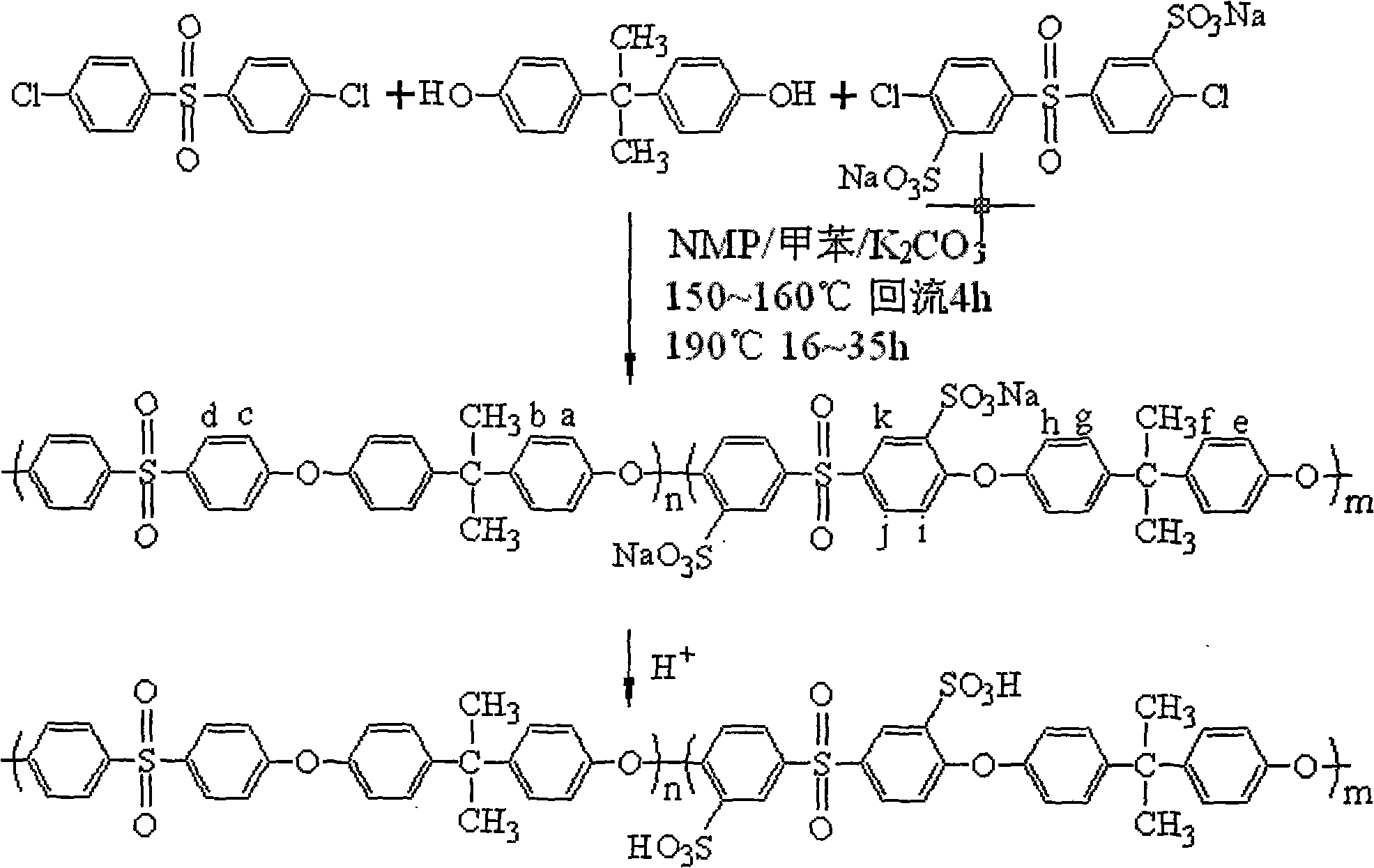

[0014] Specific embodiment one: the molecular formula of bisphenol A type sulfonated polysulfone copolymer in this embodiment is as follows:

[0015] molecular

[0016] The n and m in the formula represent the degree of polymerization; it is made of 4,4'-dichlorodiphenyl sulfone (DCDPS), sulfonated dichlorodiphenyl sulfone (SDCDPS) and bisphenol A, where 4,4'- The molar ratio of dichlorodiphenyl sulfone to bisphenol A is 5-9:10, and the molar ratio of sulfonated dichlorodiphenyl sulfone bisphenol A is 1-5:10.

[0017] The molecular formula of sulfonated dichlorodiphenyl sulfone in the present embodiment is

specific Embodiment approach 2

[0018] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the bisphenol A type sulfonated polysulfone copolymer is composed of 4,4'-dichlorodiphenyl sulfone, sulfonated dichlorodiphenyl sulfone and bisphenol A is prepared in a molar ratio of 9:1:10. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0019] Specific embodiment three: the difference between this embodiment and specific embodiment one is that bisphenol A type sulfonated polysulfone copolymer is composed of 4,4'-dichlorodiphenyl sulfone, sulfonated dichlorodiphenyl sulfone and bisphenol A is prepared in a molar ratio of 8:2:10. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com