Refrigerating machine oil for hydrocarbon refrigerant and refrigerating machine system using the same

A technology of refrigerating machine oil and refrigerant, which is applied in the field of hydrocarbon refrigerants. It can solve the problems of clogging the capillary of the expansion valve and poor switching, and achieve the effect of preventing the clogging of the capillary and suppressing wax precipitation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

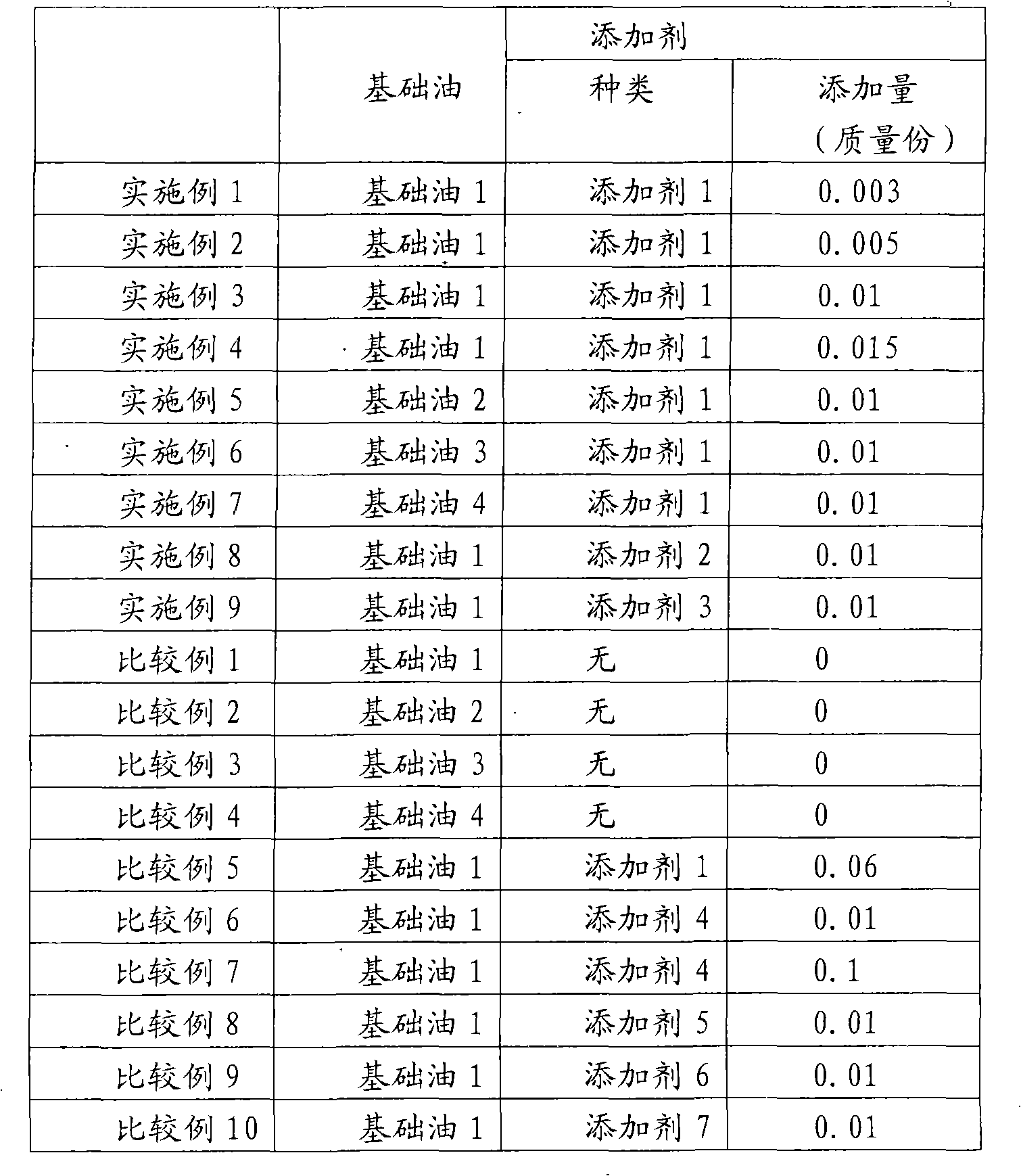

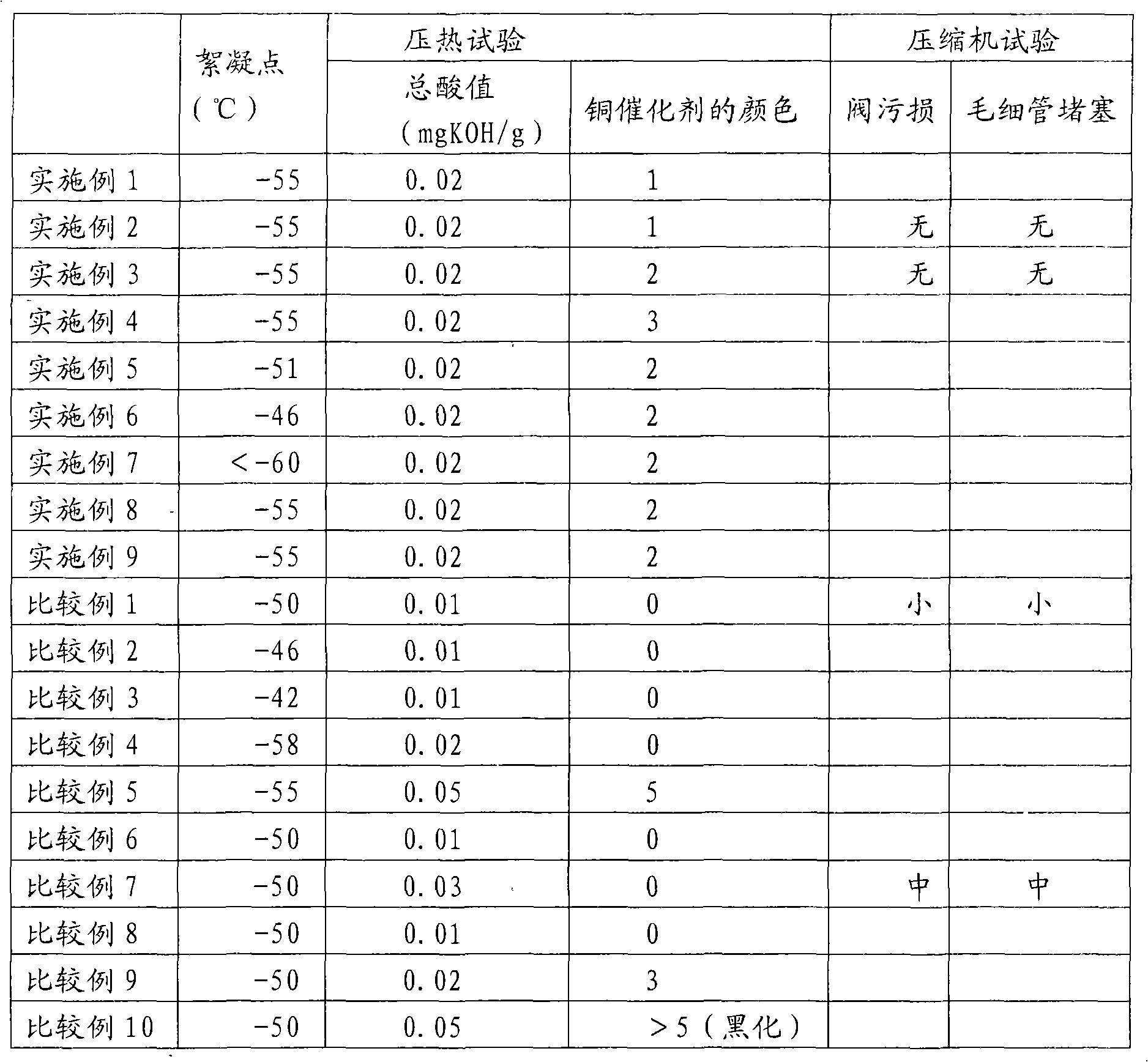

[0036] Examples are shown below, and the present invention will be described in more detail, but the present invention is not limited to these specific examples.

[0037] As base oils, Base Oils 1 to 3 (paraffin-based mineral oils) and Base Oil 4 (naphthenic-based mineral oils) having properties shown in Table 1 were used.

[0038] [Table 1]

[0039] base oil 1

base oil 2

base oil 3

base oil 4

type

Paraffin

Paraffin

Paraffin

mineral oil

Paraffin

mineral oil

Kinematic viscosity at 40°C

(mm 2 / s)100℃

10

2.6

68

8.5

137

13

12

2.7

viscosity index

75

93

89

15

Sulfur content (mass ppm)

370

300

2900

160

Nitrogen composition (mass ppm)

<1

12

10

5

Pour point (°C)

-30.0

-27.3

-27.5

-50.0

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com