Gasoline engine high pressure oil rail

A gasoline engine and oil rail technology, applied in mechanical equipment, engine components, machines/engines, etc., to improve performance and efficiency, simple and reliable structure, and promote full combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

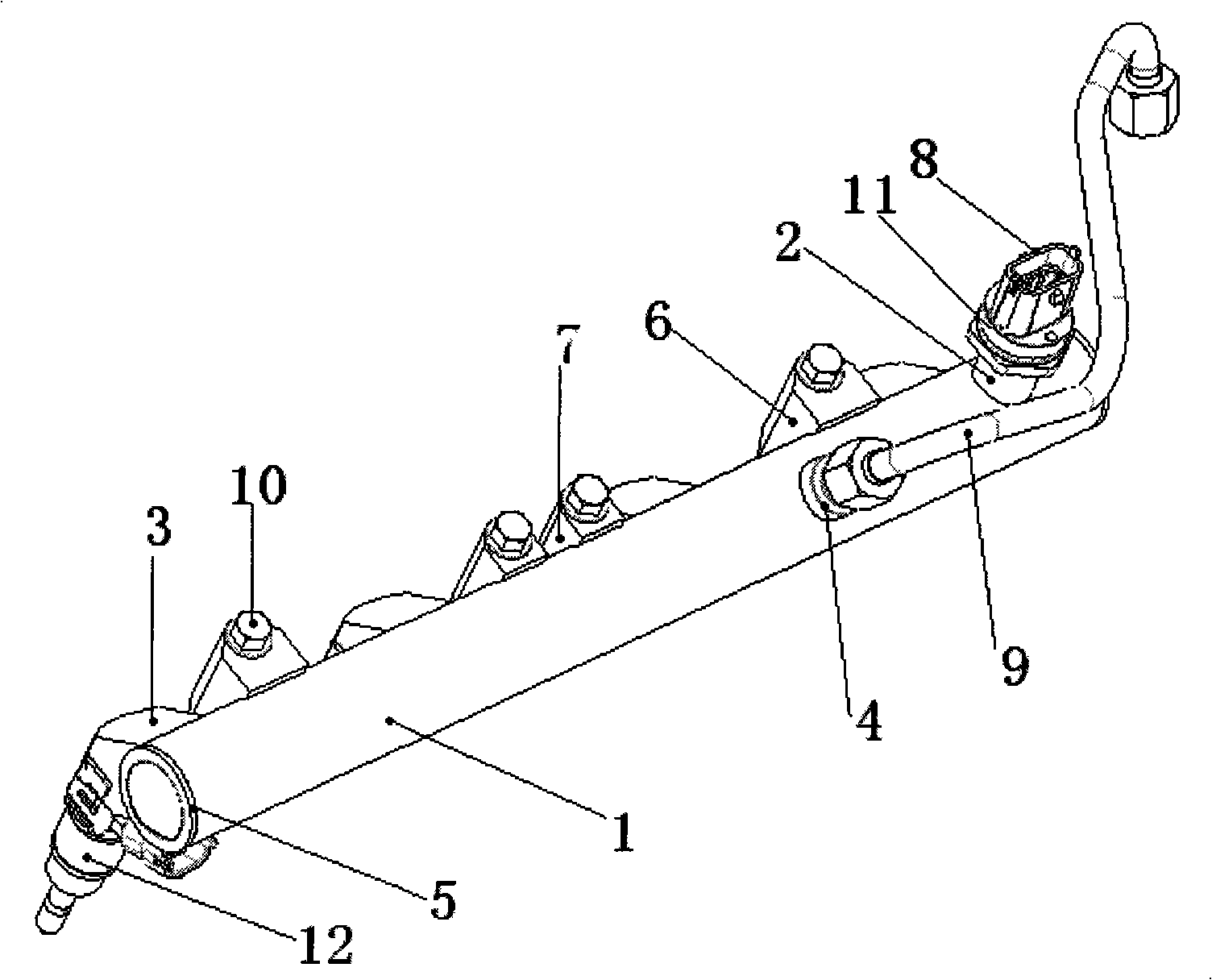

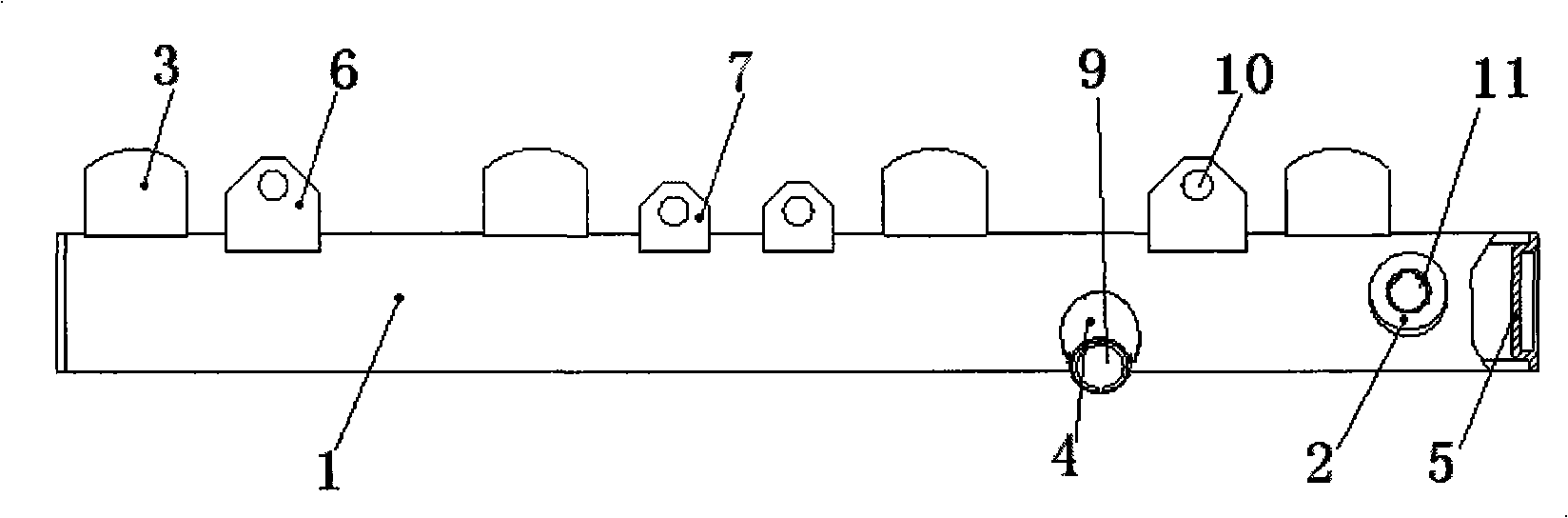

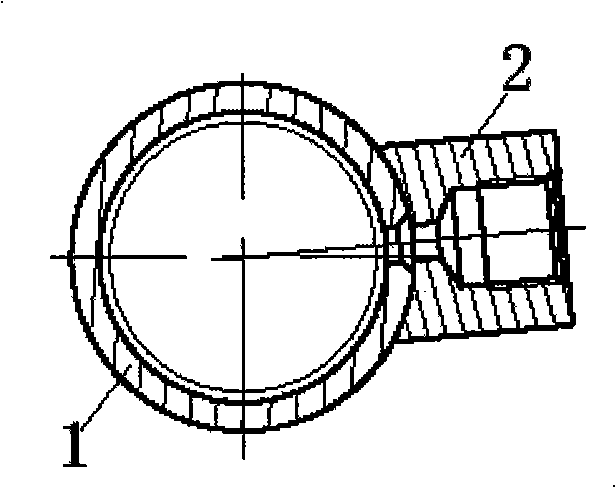

[0048] The fastened connection between the sensor bushing 2 and the fuel rail body 1, the fastened connection between the fuel injector hanger 3 and the fuel rail body 1, and the fastening of the high-pressure swirl injector 12 and the fuel injector hanger 3 connection, the fastening connection between the oil rail end cover 5 and the oil rail body 1, the fastening connection between the oil inlet pipe bushing 4 and the oil rail body 1, the support 6 at both ends of the oil rail and the middle support 7 of the oil rail and the oil rail body 1 The fastening connections are all welded connections. The welding method is brazing.

[0049] Determine the size of each key component according to the design requirements, and then process the oil rail body 1, sensor bushing 2, four injector hangers 3, oil inlet pipe bushing 4, four brackets and other components, and finally assemble and weld them according to their respective positions .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com