Seabed optical cable tension torque test method and device thereof

A technology of submarine optical cable and test method, which is applied in tension measurement, measurement device, measurement of fluid pressure, etc., can solve problems such as inability to obtain analysis results, and achieve the effect of avoiding blindness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

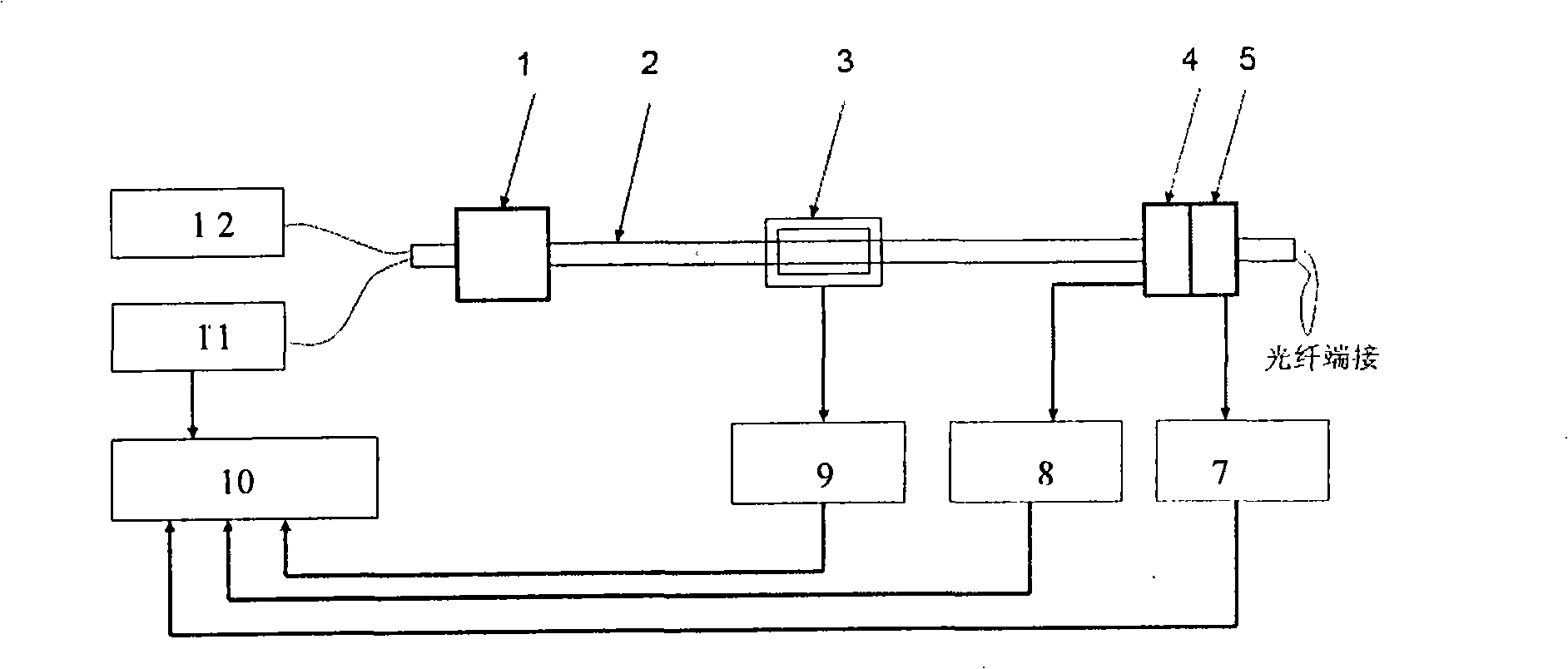

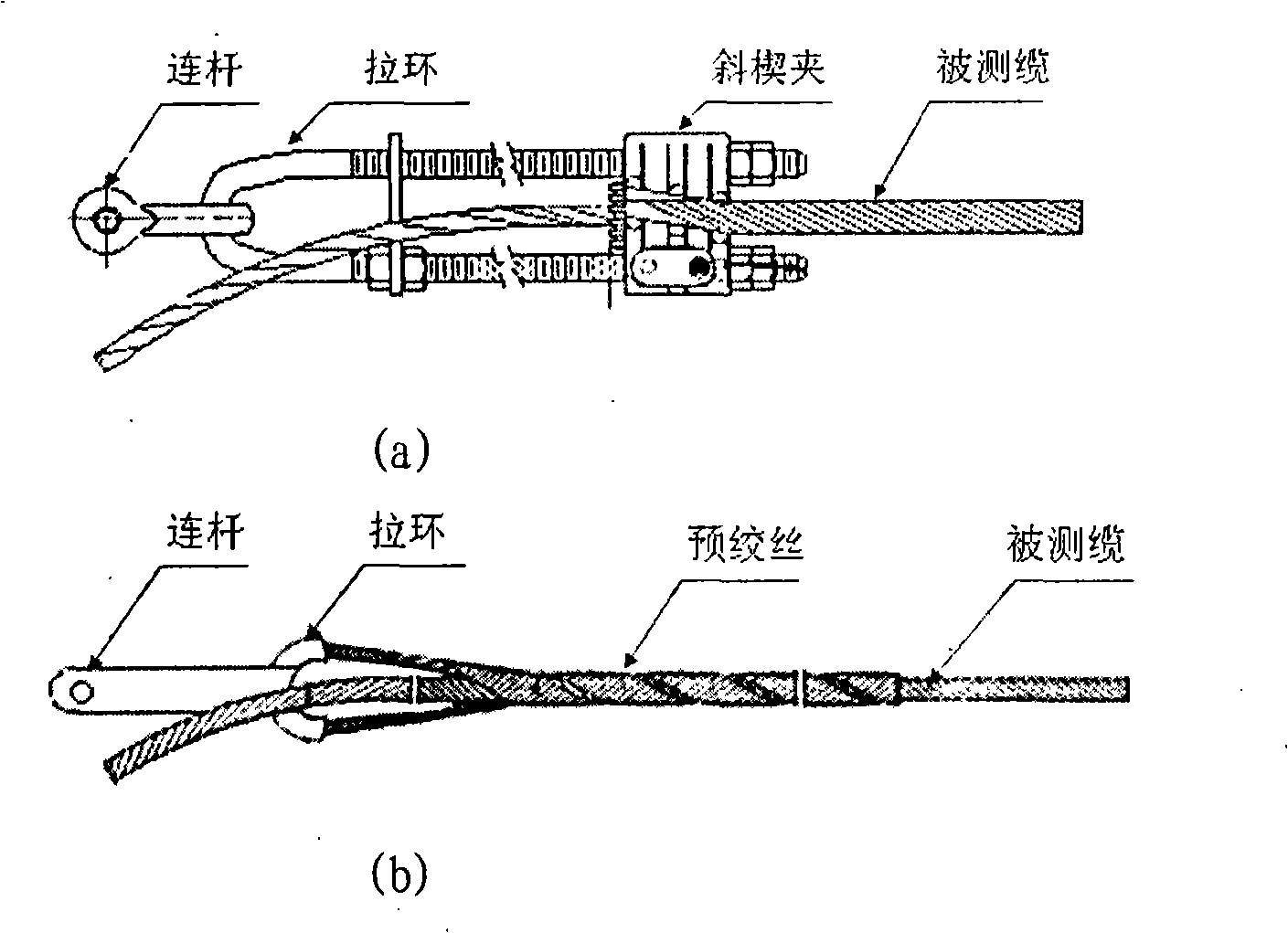

[0028] Embodiment 1. A kind of horizontal submarine optical cable tension torque test method and device refer to the attached figure 1 .

[0029] exist figure 1 Middle: 1. Fixing fixture for clamping submarine optical cable, 2. Submarine optical cable sample under test, 3. Displacement measuring device, 4. Rotating fixture with angle sensor, 5. Tension sensor, 7. Tension transducer, 8. Angle Converter, 9. Displacement converter, 10. Central processing unit, 11. Optical power meter, 12. Light source. Make preparations before the test, put the above equipment and instruments into figure 1 The installation and connection are completed, including various optical connections, electrical connections, mechanical and transmission connections. After making preparations, start to test and record the parameters of the tested submarine optical cable:

[0030] a. Turn on the light source, the light enters the optical fiber from the light source into the optical cable, and after the end...

Embodiment 2

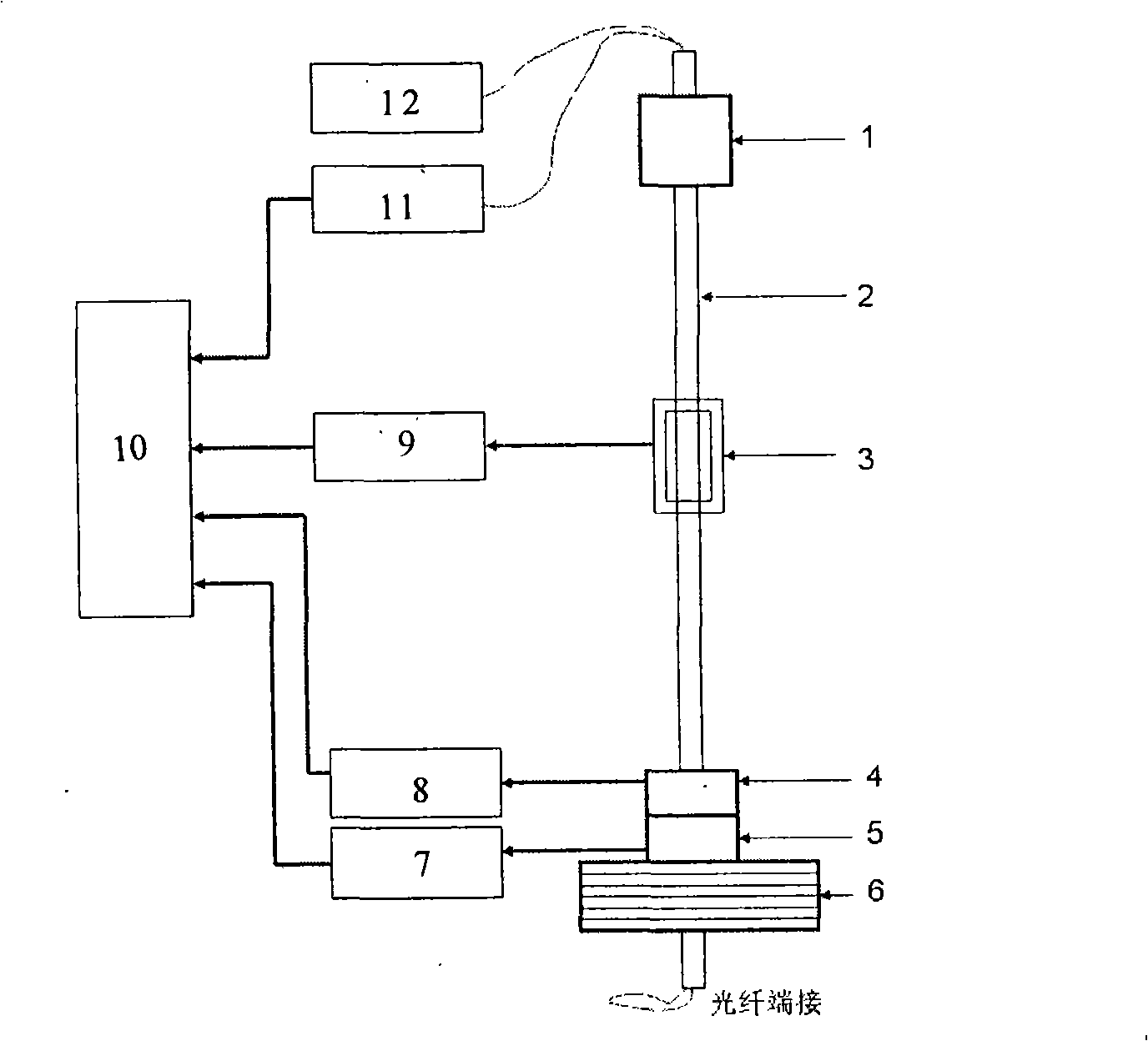

[0032] Embodiment 2, a vertical submarine cable tension torque test method and device, see the attached figure 2 , carry out tension torque detection to a submarine optical cable a, its test principle method and equipment are the same as embodiment 1, the difference is that in the vertical test device the tension force of the load-bearing fixture end of the cable can be provided by mechanical device, also can Provided by step weights and weight holders (6) aligned with the vertical axis of the cable. see test results Figure 10 Shown in curve a.

Embodiment 3

[0033] Embodiment 3, a kind of horizontal submarine optical cable tension torque test method and device refer to the attached figure 1 .

[0034] The equipment, instrument and method steps of test are the same as embodiment 1, carry out tension torque test to a submarine optical cable b, test result data see Figure 10 Shown in curve b.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com