Liquid crystal device, method of manufacturing liquid crystal device, and electronic apparatus

A technology of liquid crystal device and manufacturing method, applied in semiconductor/solid-state device manufacturing, circuits, transistors, etc., can solve problems such as poor friction, poor orientation, and increased resistance, and achieve the effect of reducing poor alignment and optimizing film thickness balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0033] (overall composition)

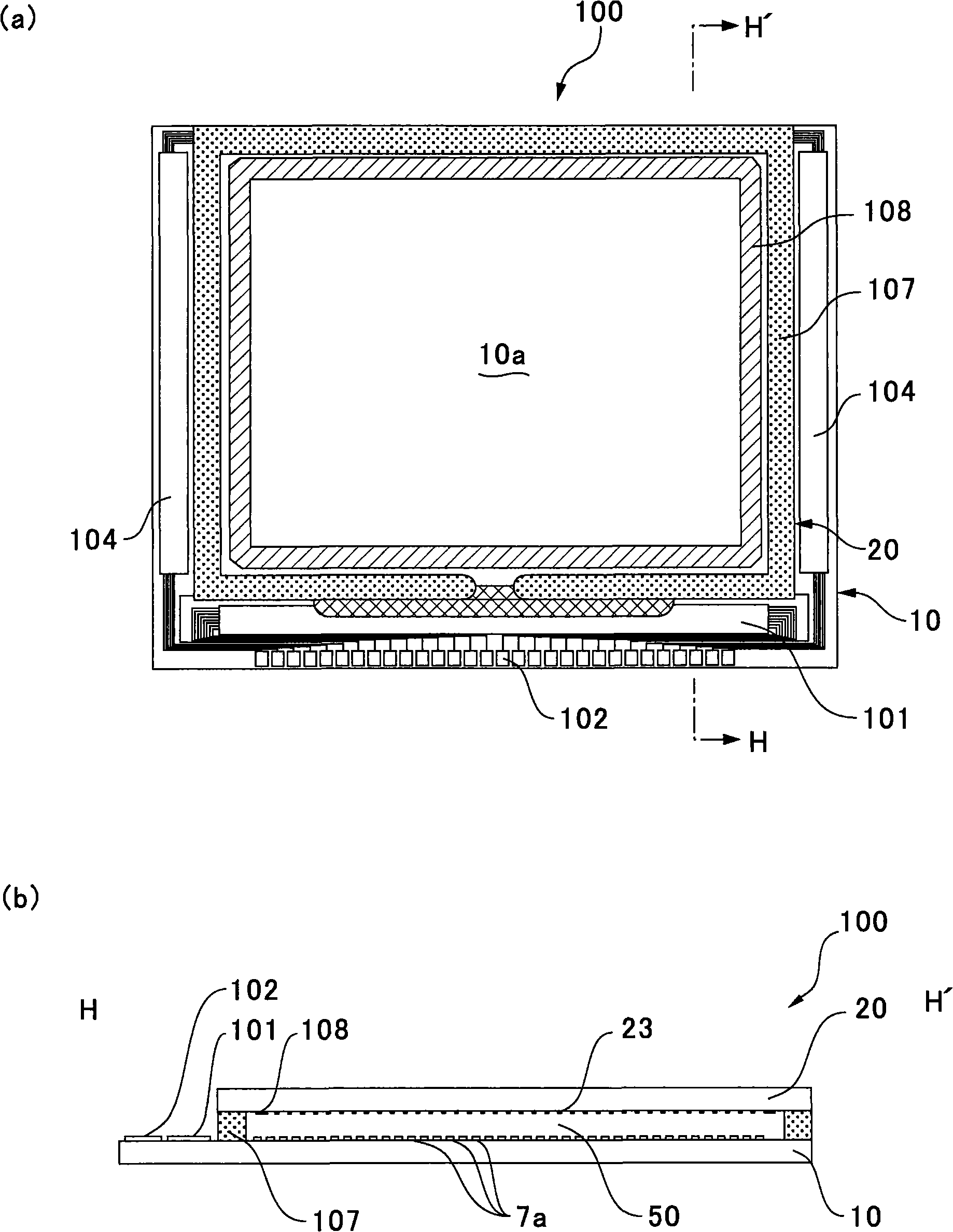

[0034] figure 1 (a) and (b) are a plan view and a H-H' sectional view of a liquid crystal device to which the present invention is applied and components formed thereon viewed from the counter substrate side, respectively.

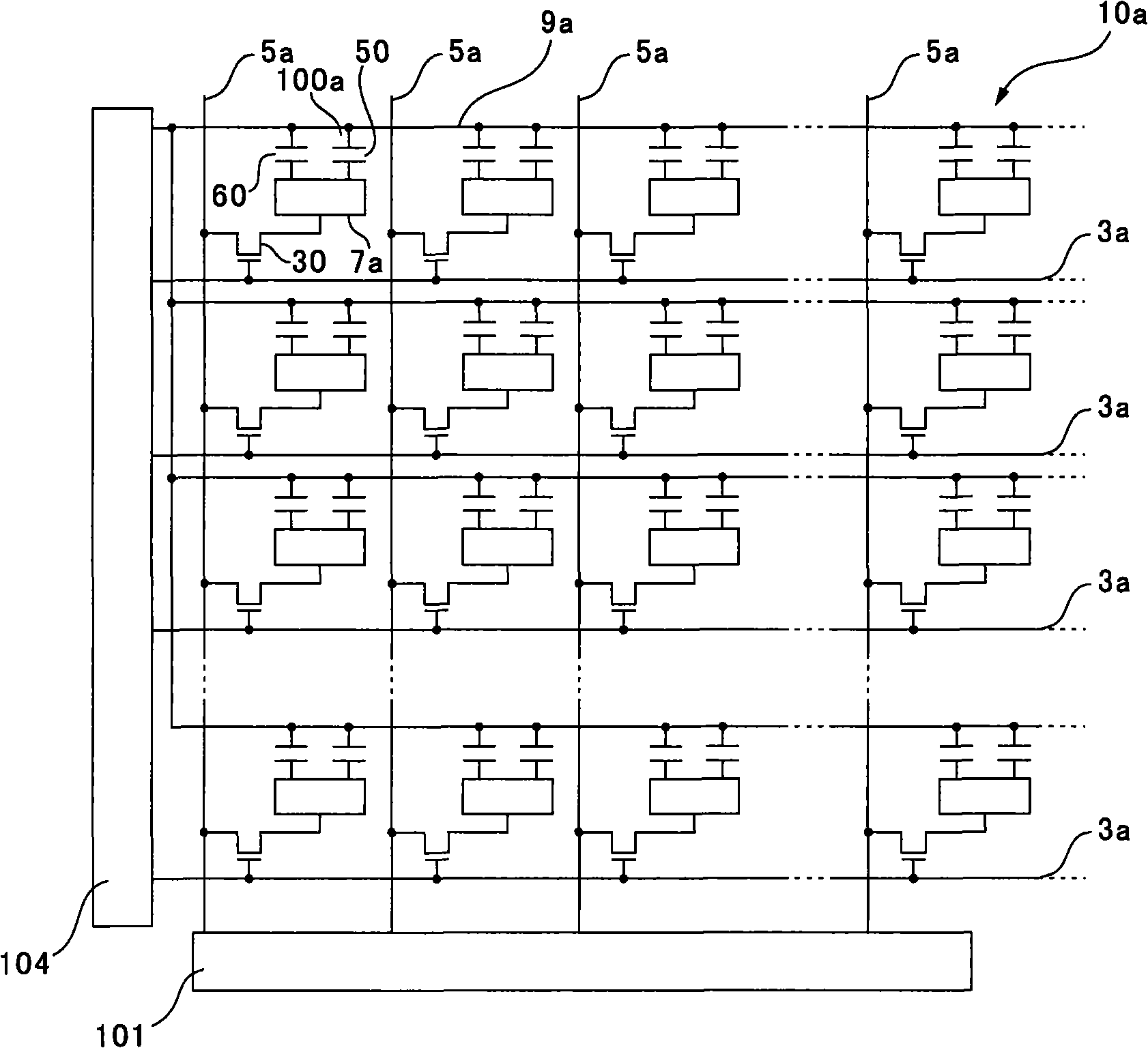

[0035] exist figure 1 (a), figure 1 In (b), the liquid crystal device 100 of this embodiment is a transmissive active matrix liquid crystal device, and the sealing material 107 is provided along the edge of the counter substrate 20 on the element substrate 10 . In the element substrate 10, in the area outside the sealing material 107, the data line driving circuit 101 and the mounting terminal 102 are arranged along one side of the element substrate 10, and the scanning line driving circuit is formed along the two sides adjacent to the side where the mounting terminal 102 is arranged. circuit 104. Furthermore, peripheral circuits such as a precharge circuit and an inspection circuit may be provided under the frame 108 ...

Embodiment approach 2

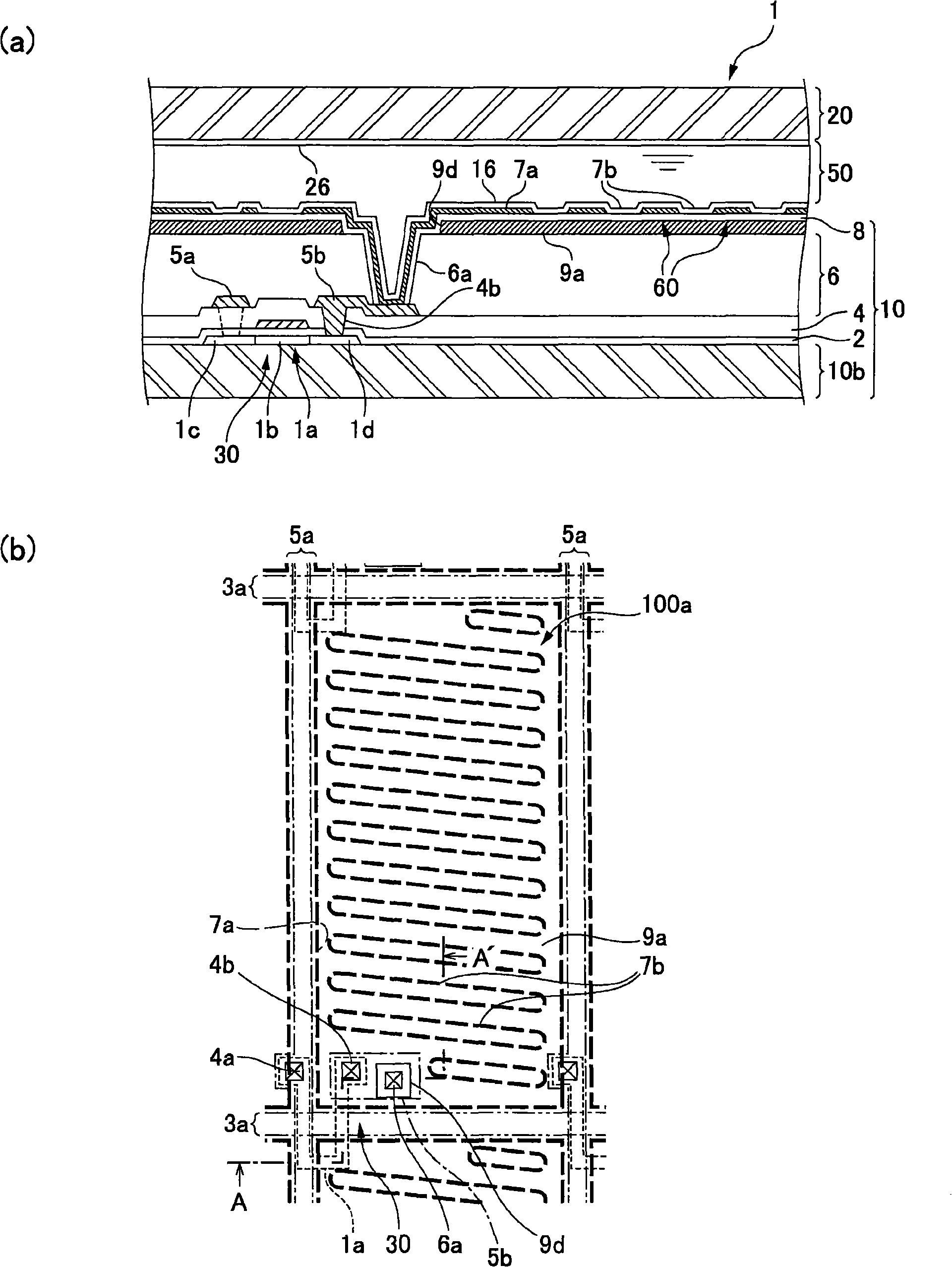

[0061] Figure 5 (a) and (b) are respectively a sectional view corresponding to one pixel of the liquid crystal device 100 in Embodiment 2 of the present invention and a plan view of pixels adjacent to the element substrate 10; Figure 5 (a), which is equivalent to image 3 The position of line B-B' in (b) is a cross-sectional view when the liquid crystal device 100 is cut. In addition, since the basic structure of this embodiment is the same as that of Embodiment 1, the same code|symbol is attached|subjected to the same part, and their description is abbreviate|omitted.

[0062] as shown in Figure 5 (b), on the element substrate 10, a plurality of transparent pixel electrodes 7a (regions surrounded by long dotted lines) are formed in a matrix for each pixel 100a, and data are formed along the vertical and horizontal boundary regions of the pixel electrodes 7a. Line 5a (indicated by a one-dot chain line), and scanning line 3a (indicated by a two-dot chain line). In additi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com