Method for forming multi-layered coating film

A multi-layer coating, coating technology, applied in the direction of coating, device for coating liquid on the surface, special surface, etc., can solve problems such as reflection or interference light affecting the coating light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

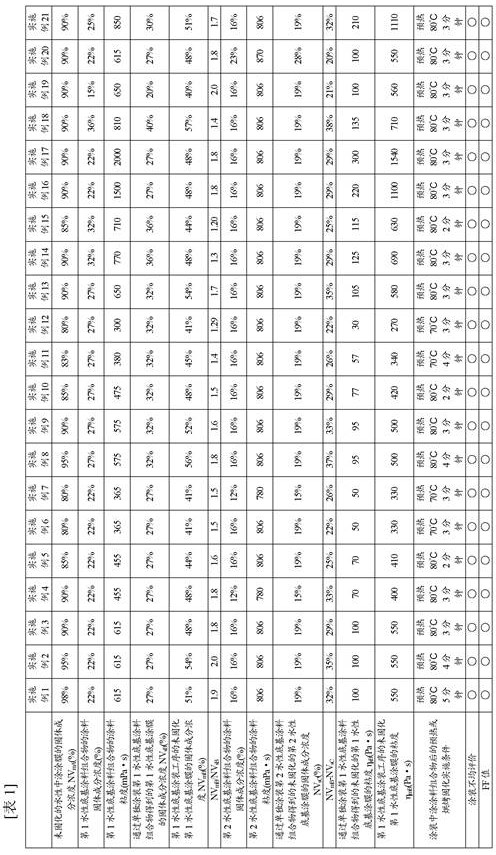

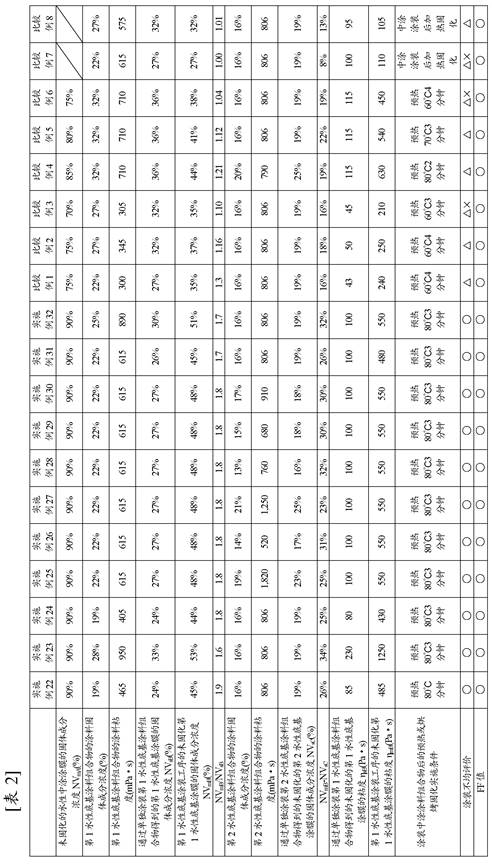

Examples

preparation example Construction

[0054] In the preparation of an acrylic resin emulsion, emulsion polymerization can be performed by heating the above monomer mixture under stirring in an aqueous medium in the presence of a radical polymerization initiator and an emulsifier. The reaction temperature may be, for example, about 30 to 100°C. The reaction time can be appropriately selected according to the reaction scale and reaction temperature, and may be, for example, about 1 to 10 hours. In emulsion polymerization, for example, the monomer mixture or monomer pre-emulsion can be added at one time or dropwise for a short time to a reaction vessel containing water and an emulsifier. By appropriate choice of such a program, the reaction temperature can be adjusted.

[0055] As said radical polymerization initiator, the well-known initiator which can be used for the emulsion polymerization of an acrylic resin can be used. Radical polymerization initiator Specifically, as a water-soluble radical polymerization in...

preparation example 1

[0182] Preparation Example 1 Preparation of Acrylic Resin Emulsion

[0183] 330 g of deionized water was added to the reaction vessel, and the temperature was raised to 80° C. while mixing and stirring in a nitrogen stream. Next, 11.25 parts of acrylic acid, 139 parts of n-butyl acrylate, 75 parts of methyl methacrylate, 187 parts of n-butyl methacrylate, 75 parts of 2-ethylhexyl methacrylate, 150 parts 2-hydroxyethyl methacrylate, 112 parts of styrene, 11.2 parts of チオカルルコール 20 (n-dodecyl mercaptan, manufactured by Kao Corporation, the active ingredient is 100%) and 74.3 parts of LATEMUL PD-104 (emulsifier , manufactured by Kao Corporation, the active ingredient is 20%) and 3% in the monomer emulsion composed of 300 parts of deionized water, and an initiator solution composed of 2.63 parts of ammonium persulfate and 90 parts of deionized water 30% of the amount was added dropwise to the reaction vessel in parallel over 15 minutes. After completion of the dropwise addition, ...

preparation example 2

[0186] Preparation Example 2 Preparation of Polyester Aqueous Dispersion

[0187] Add 250 parts of trimethylolpropane, 824 parts of adipic acid, and 635 parts of cyclohexanedicarboxylic acid into a reaction vessel equipped with a stirrer, nitrogen introduction pipe, temperature control device, condenser, and decanter, and heat up To 180 ° C, the polycondensation reaction was carried out until no water distilled out. After cooling to 60° C., 120 parts of phthalic anhydride was added, the temperature was raised to 140° C., and the temperature was maintained for 60 minutes to obtain a polyester resin having a number average molecular weight of 2,000 measured by GPC. Add 59 parts of dimethylaminoethanol (equivalent to 80% of the acid value of the resin (neutralization rate is 80%)) at 80°C, and then put in 1920 parts of deionized water and stir to obtain a resin solid The component is an aqueous polyester dispersion of 45% by mass. The resin solid content equivalent hydroxyl val...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com