Preparation of high-strength aluminum alloy for outer casing of electronic product

A technology for electronic products and aluminum alloys, which is applied in the field of high-strength aluminum alloys, can solve the problems of difficult welding of aluminum alloys, low formability of 2xxx series alloys, and inability to weld, and achieve the effect of easy welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

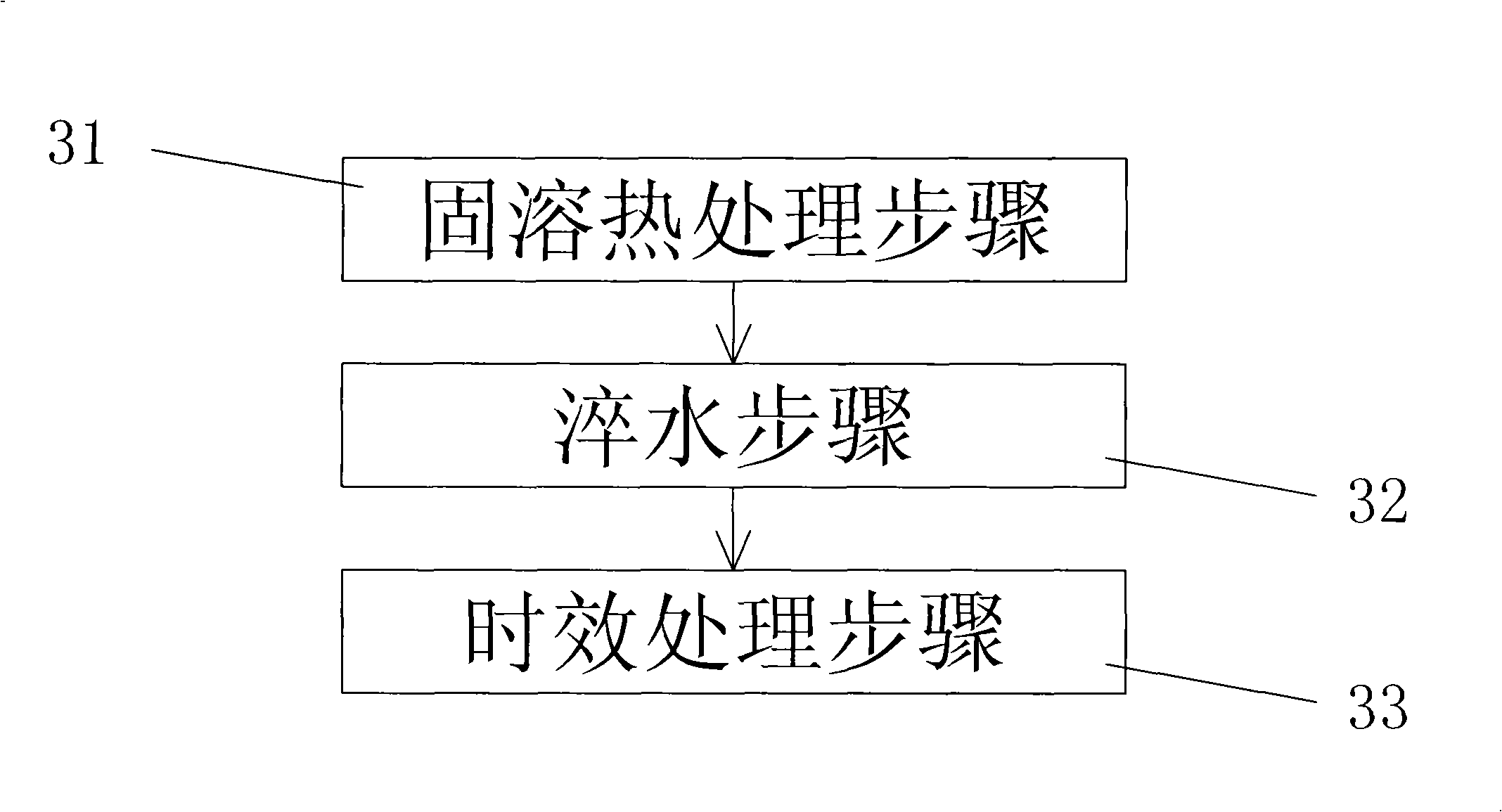

[0031] see Figure 5 Shown, the present invention is to provide a kind of method for the manufacture of the high-strength aluminum alloy that is used as electronic product housing part, and it comprises the following steps:

[0032] A material preparation step 41, the material preparation step 41 is to provide a composition containing 1.1-2.5wt% copper, 0.7-1.3wt% magnesium, 0.7-1.3wt% silicon, and the rest is aluminum, and of course it also contains unavoidable impurities. Ordinary aluminum alloy formed, and then perform solution treatment step 42;

[0033] A solid solution treatment step 42, the solid solution treatment step 42 is to heat the aluminum alloy prepared in the material preparation step 41 to 540°C±10°C for 30-90 minutes, and then perform the quenching step 43;

[0034] A quenching step 43, the quenching step 43 is to rapidly cool the aluminum alloy after the solid solution treatment step 42 with water, and then perform the preheating step 44;

[0035] A preheati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com