Rocker-arm support of engine compression casting air cylinder head for booster vehicle as well as light motorcycle

A cylinder head and motorcycle technology, applied in the field of rocker arm seat, can solve the problems of high cost, difficult processing and assembly, complex structure, etc., and achieve the effects of compact structure, good reliability, and simple processing operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

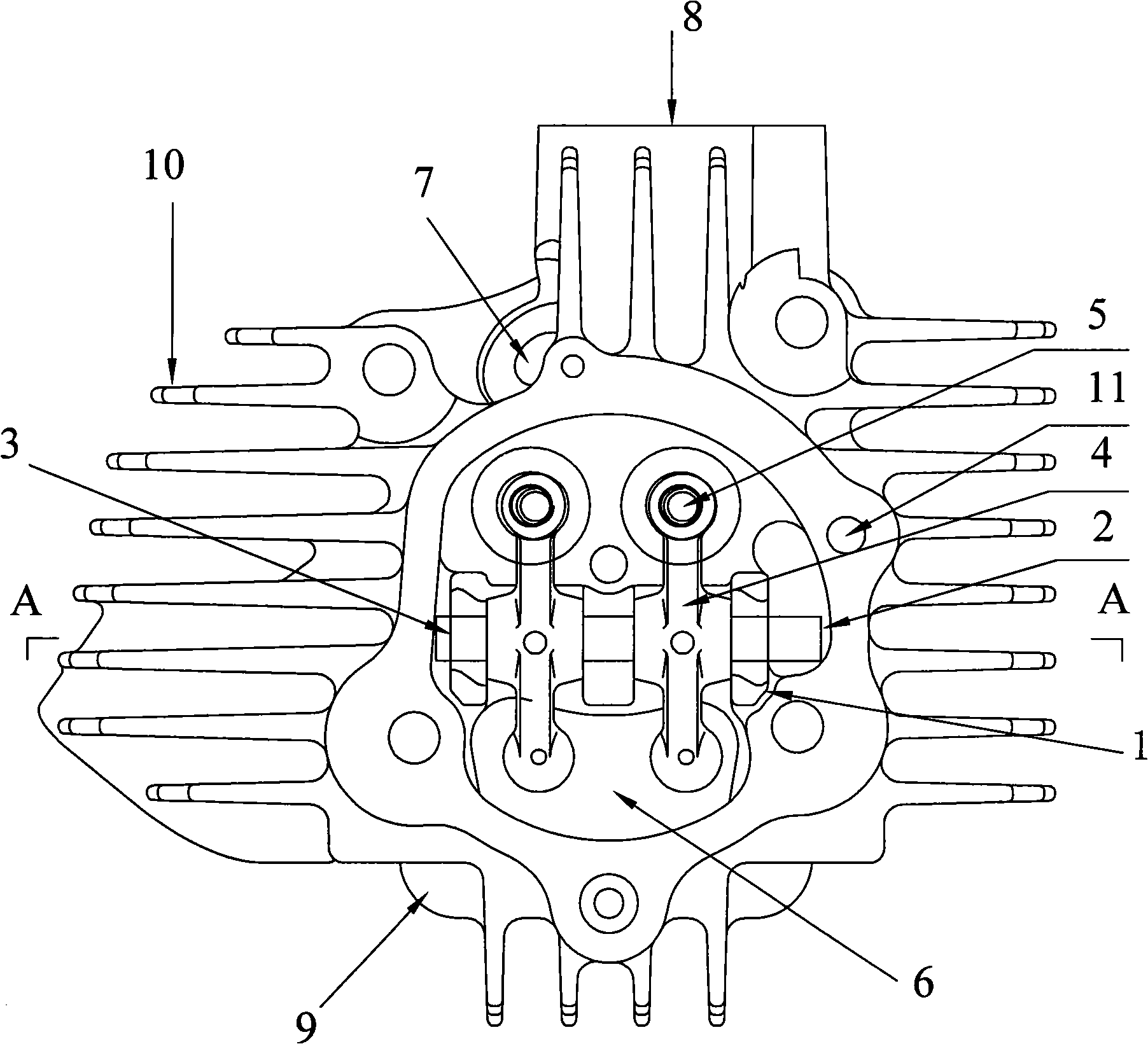

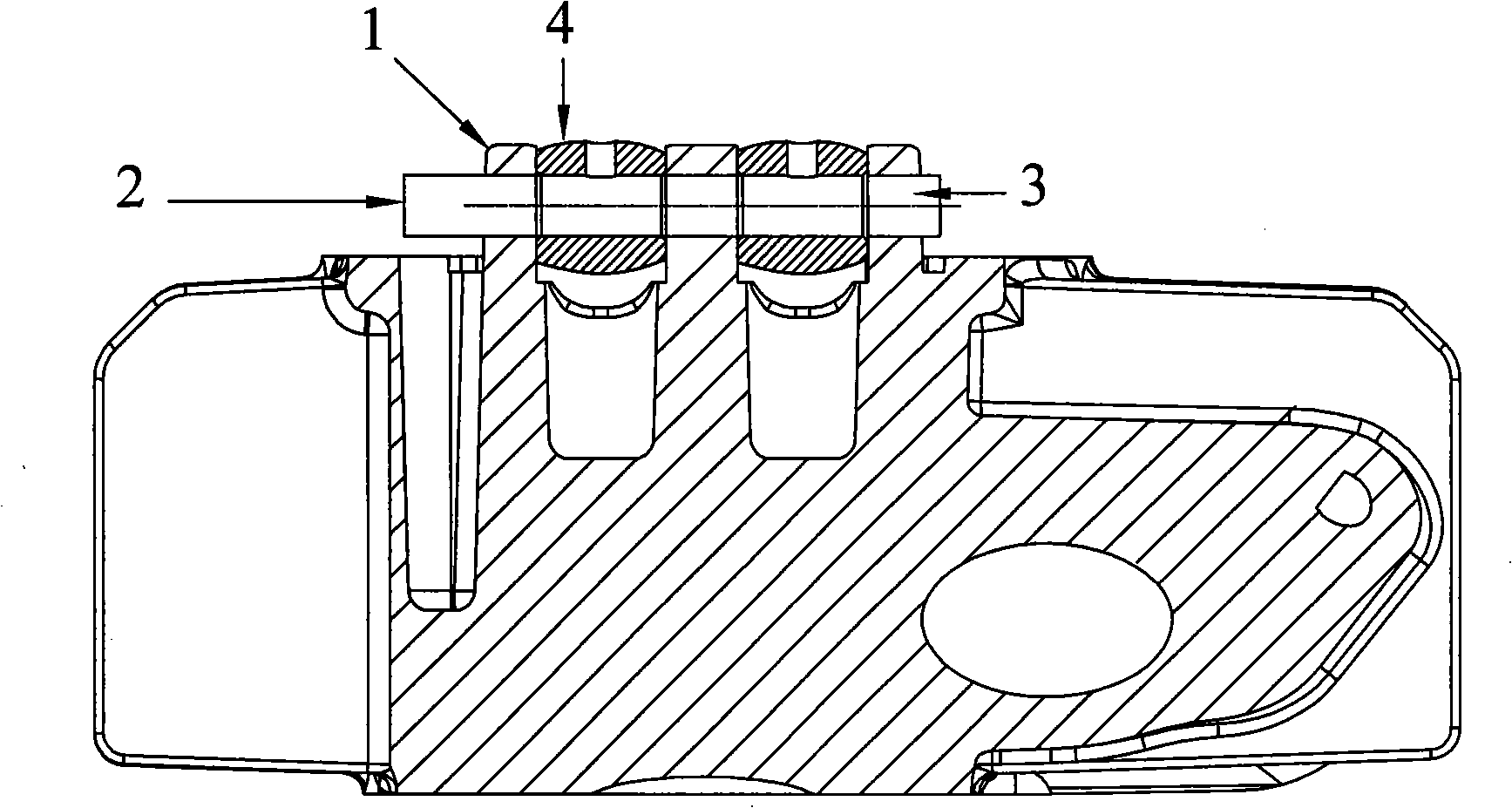

[0012] As shown in the figure: a cooling fin 10 is arranged on the cylinder head body, a cylinder head rocker arm seat 1 is integrally die-cast on the cylinder head body, a rocker arm shaft hole 3 is arranged on the cylinder head rocker arm seat 1, and a rocker arm shaft hole 3 is installed on the rocker arm shaft hole 3 has a rocker shaft 2 inside, and two rocker arms 4 are arranged on the rocker shaft 2, and valve adjustment bolts and adjustment nuts 5 are arranged on the end of the rocker arm 4 corresponding to the intake valve and the exhaust valve. The other end is located in the push rod chamber 6, and the rocker arm 4 can swing around the rocker arm shaft 2.

[0013] An air inlet 8 and an exhaust port 9 are arranged on the cylinder head body, wherein the air inlet 8 communicates with the intake valve arranged in the cylinder head body, and the exhaust port 9 communicates with the exhaust valve arranged on the cylinder head body. connected. A spark plug hole 7 for insta...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap