On-position type gas analysis system with on-position calibration function

A gas analysis system and analysis system technology, applied in the field of on-site gas analysis systems, can solve the problems of high processing and installation accuracy, complex devices, and low difficulty in installation and debugging, and achieve low assembly accuracy requirements, simple devices, and calibration reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

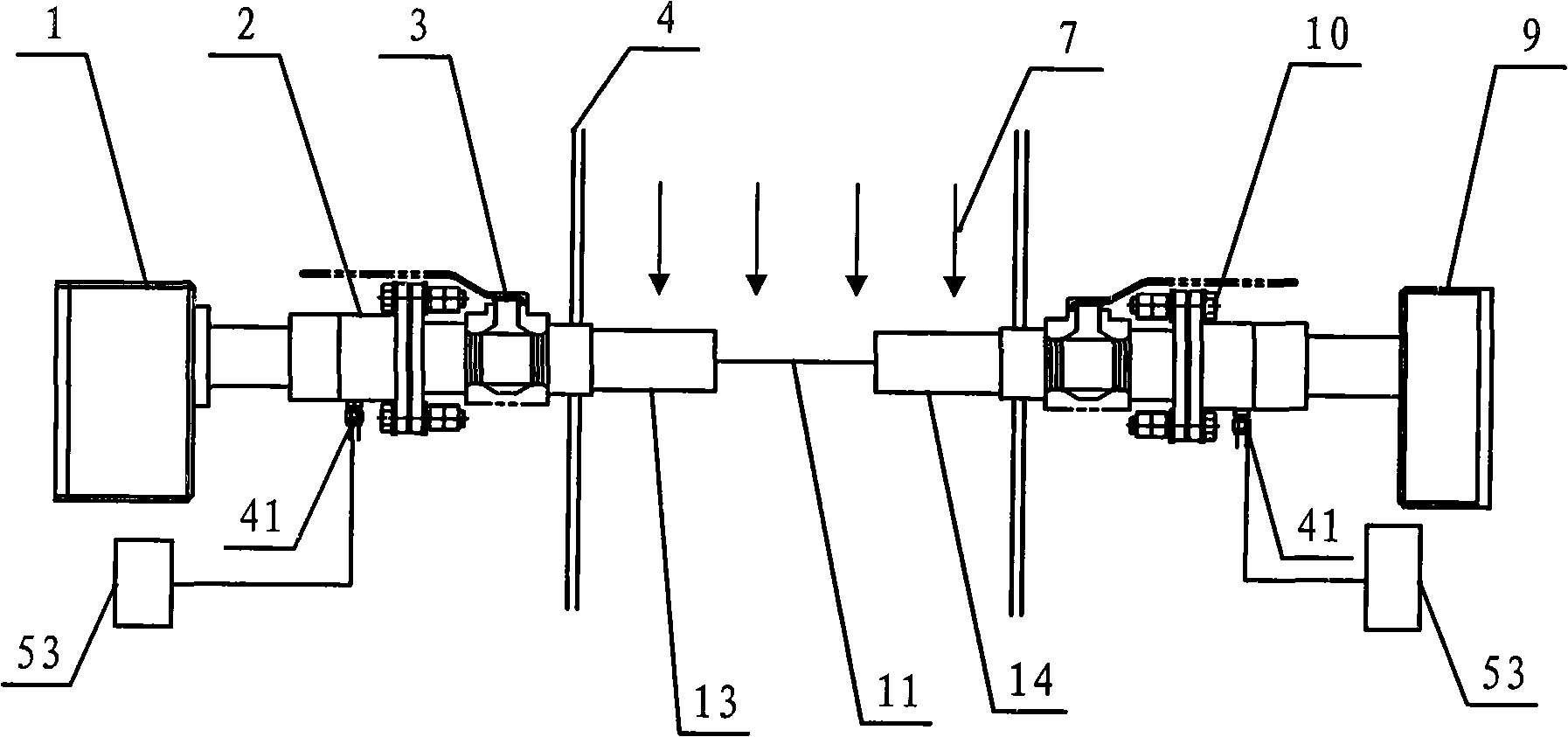

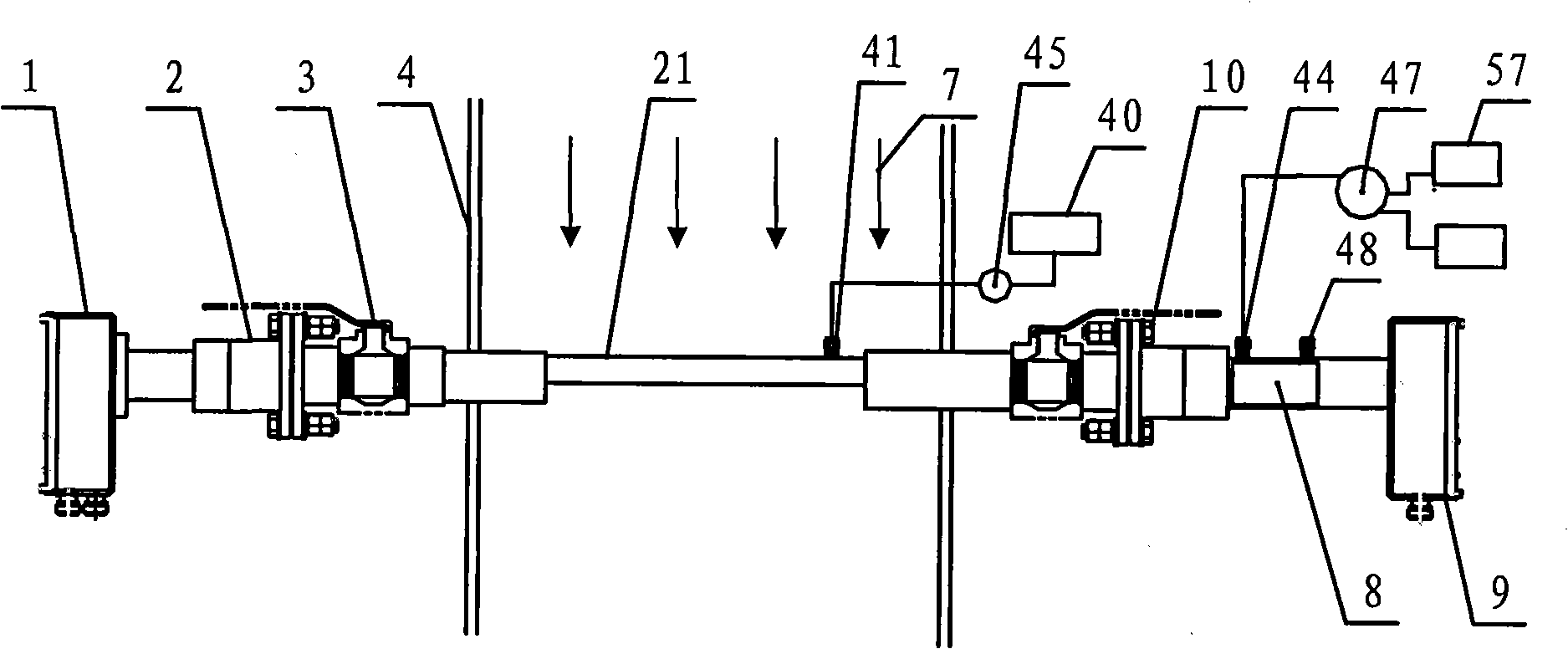

[0025] Such as figure 2 As shown, an on-site gas analysis system with an on-site calibration function is a non-dispersive infrared spectroscopy (NDIR) gas analysis system, including a light emitting device 1, a light receiving device 9, a signal analysis device, a mechanical connection structure and measuring tube. The light-emitting device 1 and the light-receiving device 9 are fitted on the measured process gas pipeline 4 through a mechanical connection structure (including a flange mating body 2 and a valve 3 ). The optical path between the light-emitting device 1 and the light-receiving device 9 can be adjusted by adjusting the bolt 10 on the mechanical connection structure to squeeze the O-ring in the middle of the flange mating body 2 . The analysis system also includes additional tubes and control means.

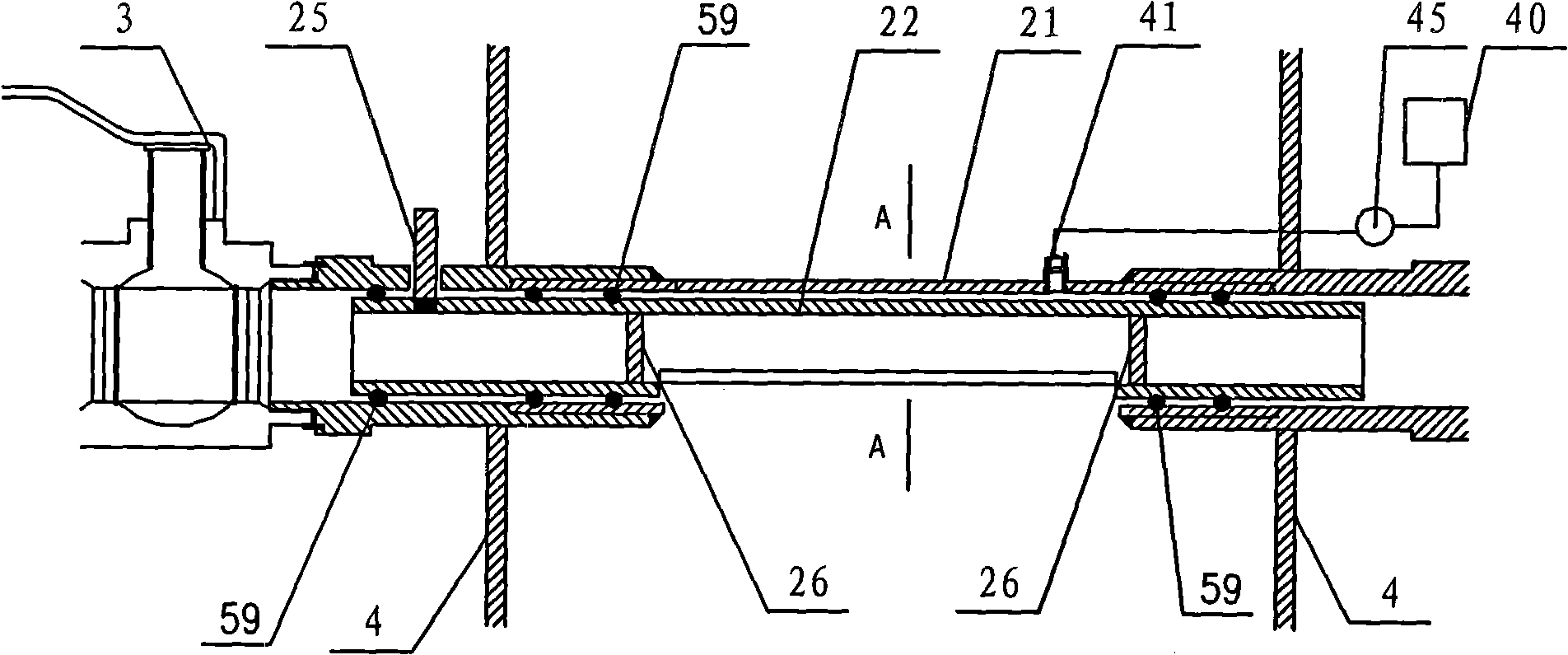

[0026] Such as image 3 As shown, the measuring tube, that is, the large C-shaped tube 21 is installed in the measured gas pipeline 4, and its two ends are connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com