Capacitance testing circuit and capacitance-type sensor interface circuit chip thereof

A capacitive sensor and capacitance detection technology, applied in the direction of measuring resistance/reactance/impedance, instruments, measuring devices, etc., can solve the problems of discounting the advantages of micro-sensors, high manufacturing repeatability, and low reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

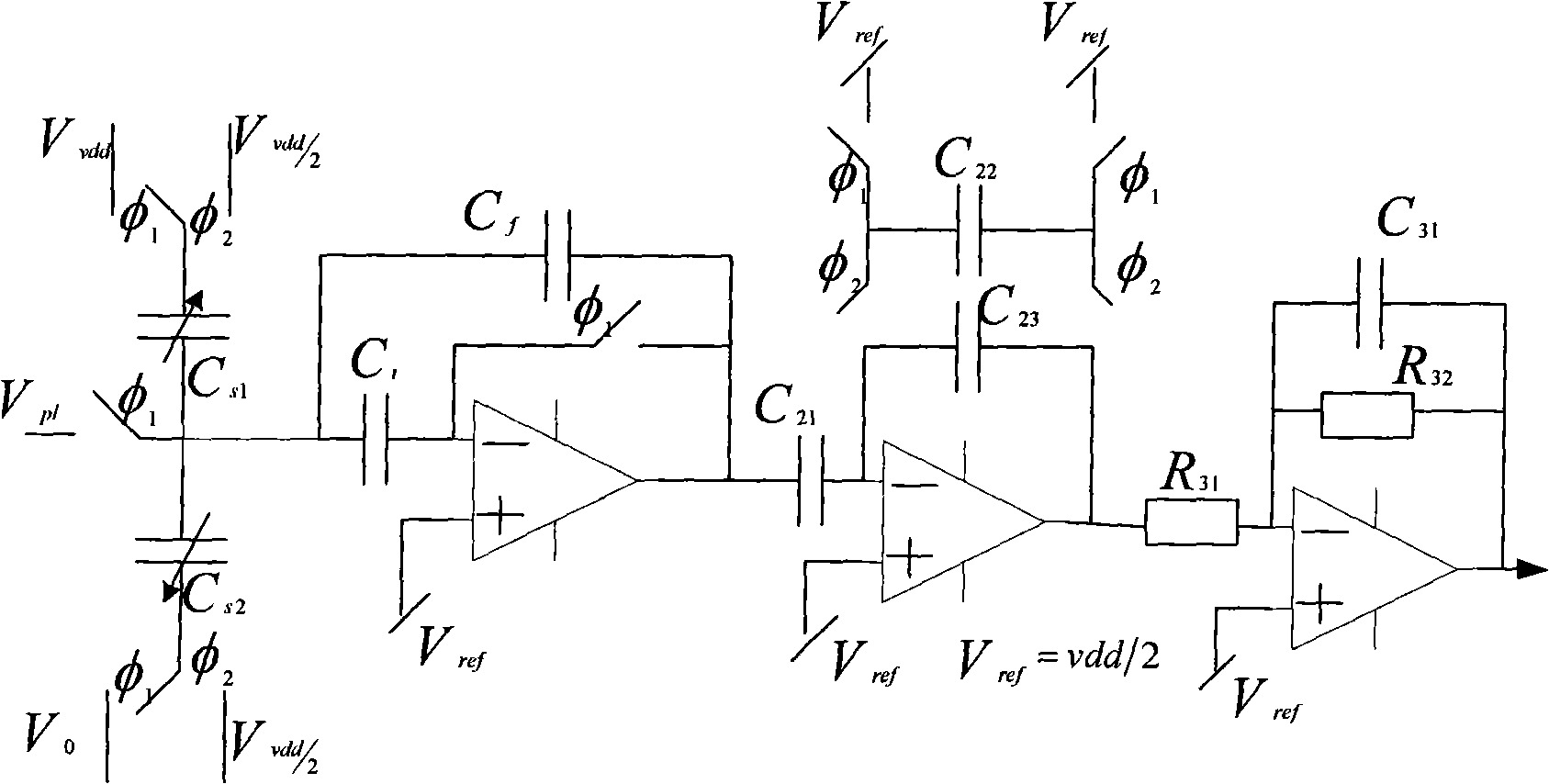

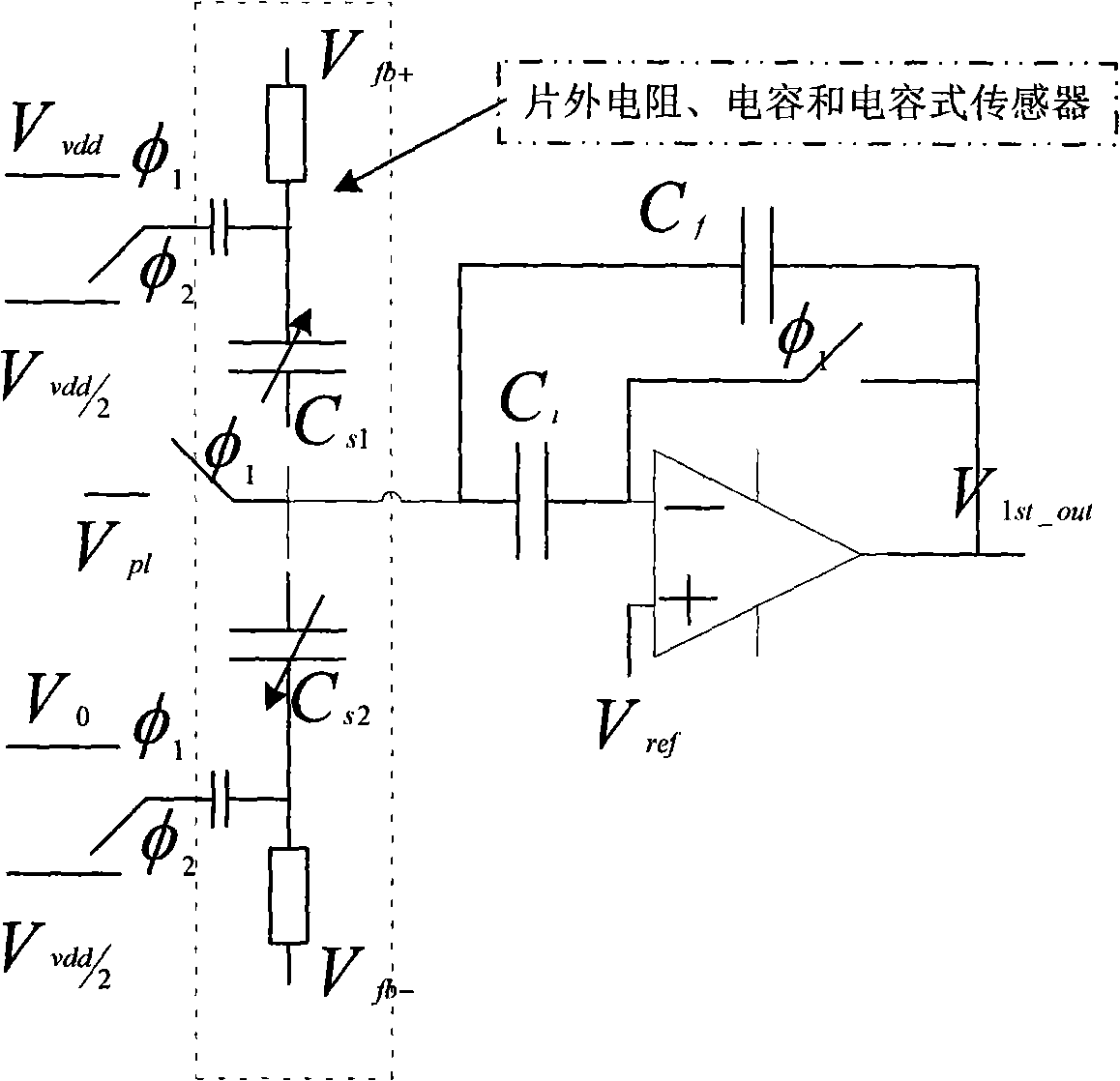

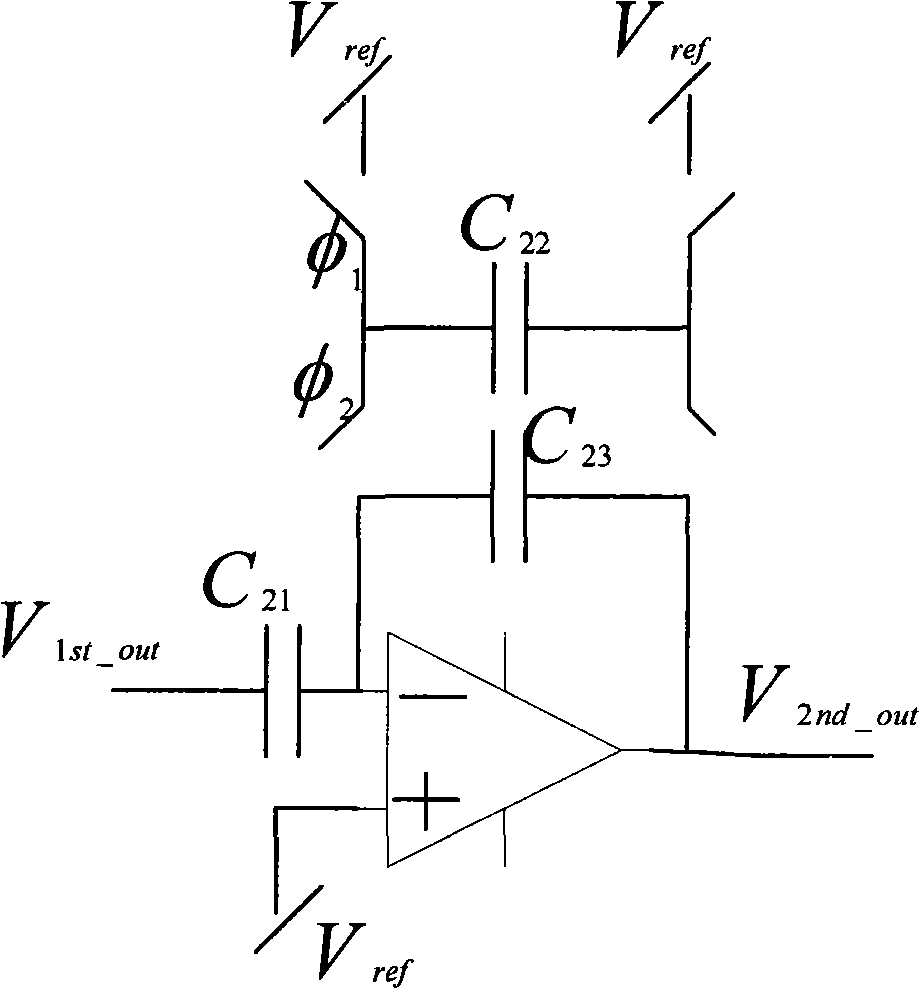

[0032] The specific implementation manners of the capacitance detection circuit and the capacitive sensor interface circuit chip used for capacitance detection of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0033] like figure 1 As shown, the capacitance detection circuit of the present invention includes: a capacitance readout front-end circuit, a demodulation amplifier circuit whose input terminal is connected to the capacitance readout front-end circuit, and a buffer amplifier circuit whose input terminal is connected to the demodulation amplifier circuit.

[0034] figure 1 shows that the capacitance detection circuit works in the first clock phase φ 1 and the second clock phase φ 2 Case. Among them, the preamplifier is the input end of the circuit, which amplifies the small capacitance change from the sensor with low noise, and the output signal of the preamplifier is input to the demodulation amplifier circuit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com