Method for preparing location hole of flexible circuit board

A flexible circuit board and manufacturing method technology, which is applied in the directions of printed circuit manufacturing, printed circuits, electrical components, etc., can solve the problems of inaccurate positioning holes, low efficiency, easy occurrence of waste products, etc., and achieve the effect of accurate position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

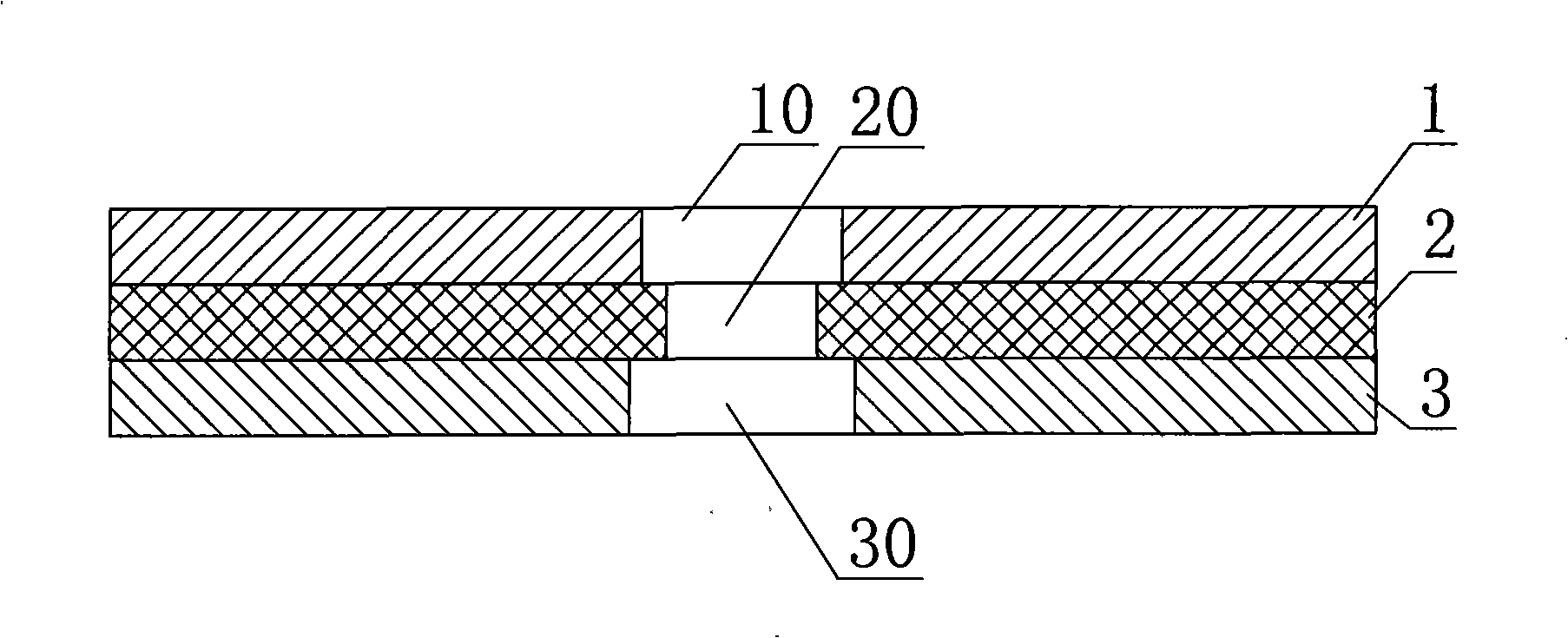

[0020] see figure 1 , a method for manufacturing a positioning hole of a flexible circuit board of the present invention, the steps comprising:

[0021] ① Bottom hole and top hole opening: Bottom hole 30 corresponding to the position of the positioning hole 20 to be opened on the copper foil 2 is set on the bottom cover film 3, and the diameter of the bottom hole 30 is equal to the positioning hole 20 on the copper foil 2 The aperture plus the position error between the negative circle image on the negative film and the bottom hole 20 during exposure, for example, the aperture of the positioning hole 20 on the copper foil 2 is 2.0mm, and the negative circle image on the negative film during exposure The position error between the sexual circle image and the bottom hole 20 is 0.4mm, then the aperture of the bottom hole 30 is equal to 2.8mm;

[0022] On the top cover film 1, a top hole 10 corresponding to the position of the positioning hole 20 to be opened on the copper foil 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com