Production device for acrylic nitrile and method for controlling temperature of reactor

A technology for production devices and reactors, which is applied to electric controllers, controllers with specific characteristics, and temperature control using electric methods, which can solve the problem of increasing the burden on the actuator, shortening the service life of the actuator, and frequent changes in control quantities. problems, to achieve the effect of stable temperature control, stable changes and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

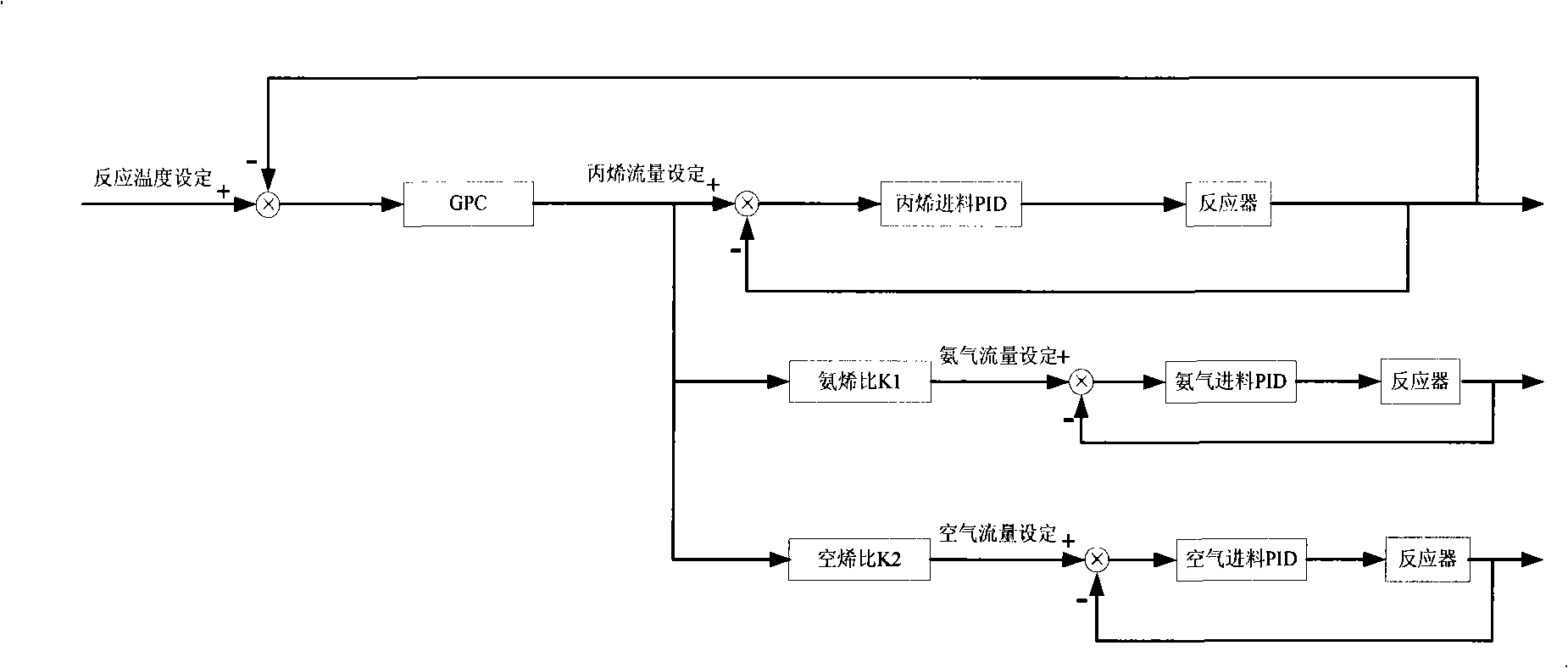

[0025] Acrylonitrile production device of the present invention, its preferred embodiment is as figure 1 As shown, the reactor is included, and the reactor is provided with a temperature control loop, and the temperature control loop includes a GPC controller and a feed control loop. The output end of the GPC controller is connected with the input end of the feed control loop, and the two form a cascade control loop.

[0026] When performing temperature control, the GPC controller first uses the GPC control algorithm to correct the set value of the feed flow rate of the reactor according to the temperature information of the reactor, and obtains the actual set value of the feed flow rate; The material control loop adjusts the feed flow rate to realize the control of the reactor temperature. Through the two-stage control, the temperature control of the reactor can be stabilized, the change of the actuator is stable, and the service life is long.

[0027] The specific feed con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com