Sewing machine button eye stitch strain automatic adjuster and its method

A technology of automatic adjustment and tension adjustment, applied in sewing equipment, sewing machine components, program-controlled sewing machines, etc., can solve the problems of uneven product quality, low production efficiency, and increased labor costs, etc., to reduce production costs, improve Production efficiency, the effect that is conducive to mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

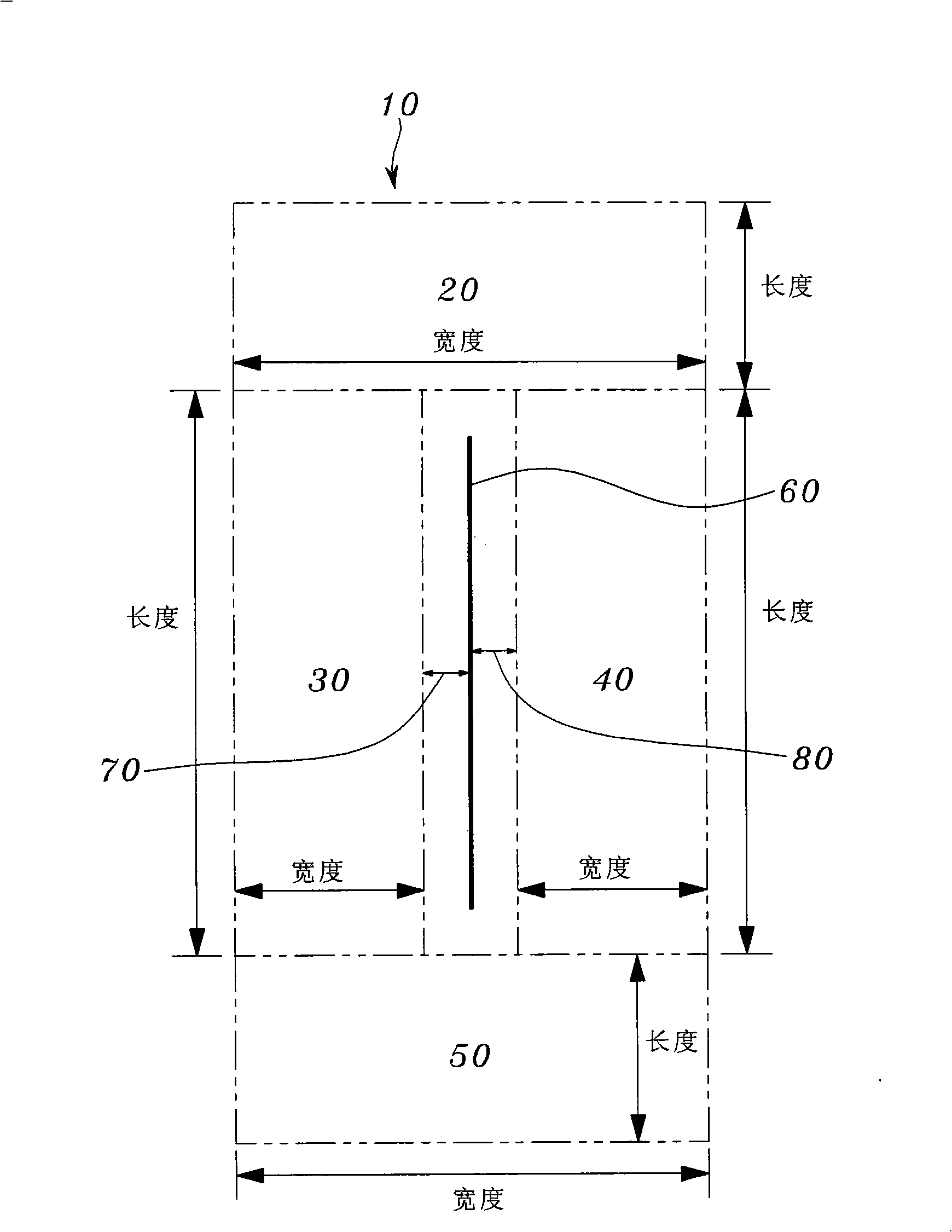

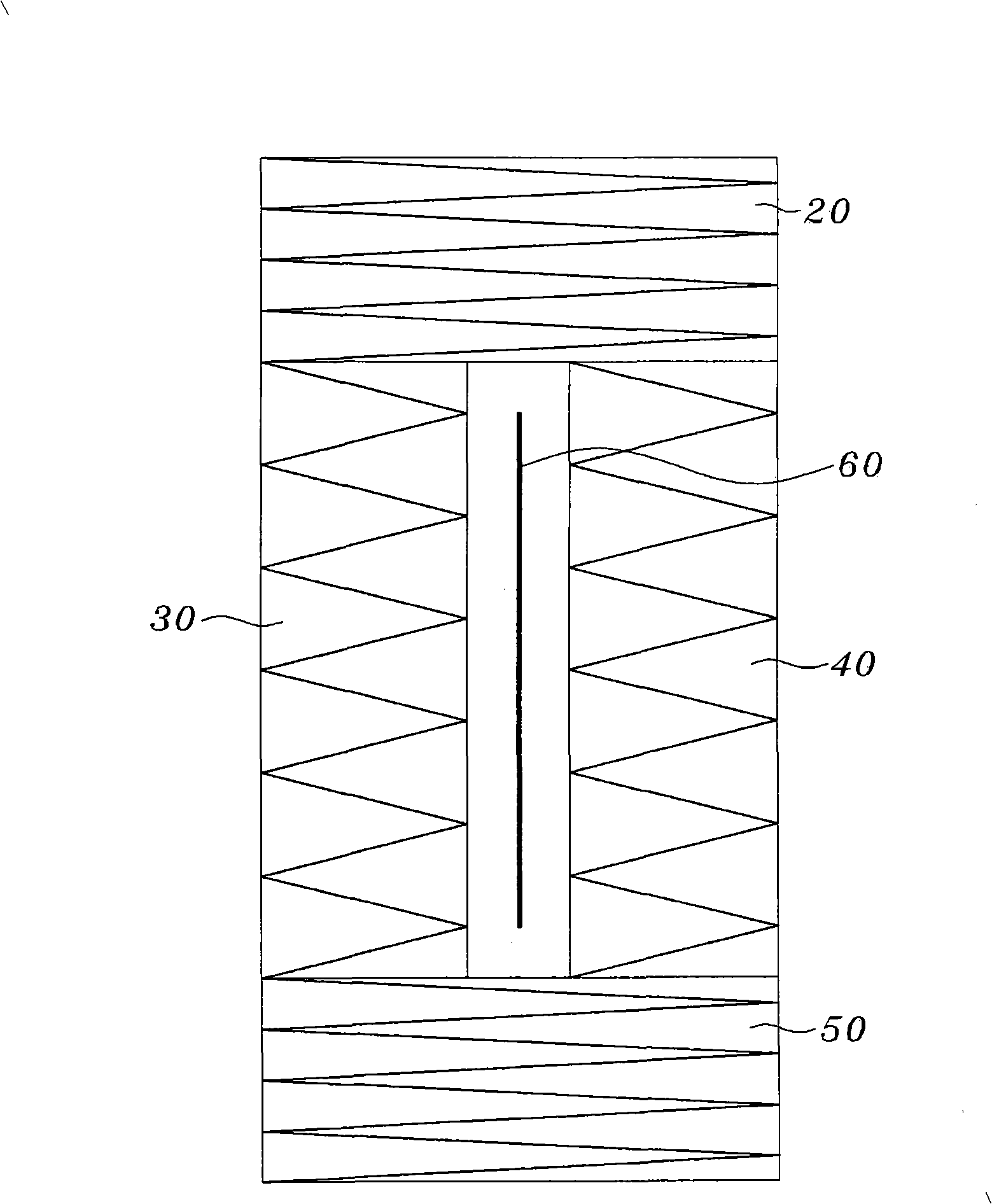

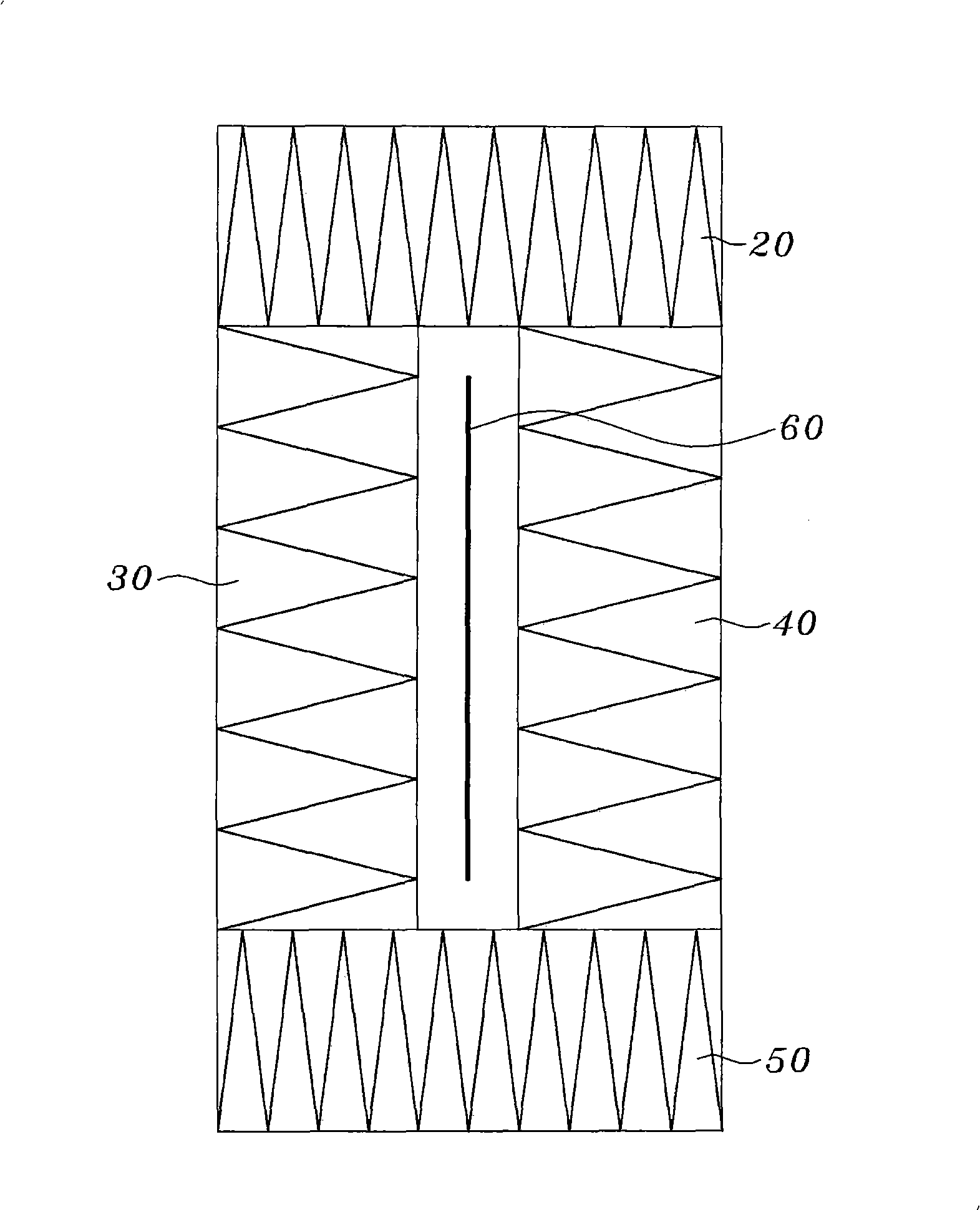

[0038] The buttonhole suture tension automatic regulator of the sewing machine of the present invention with the above-mentioned structure and its method will be further described below with reference to the accompanying drawings.

[0039] In the drawings of the present invention, Figure 4 It is the functional structure diagram of the buttonhole suture tension automatic regulator of the sewing machine of the present invention; Figure 5 It is a front view of the panel part of an embodiment of the present invention; Figure 6 It is a flow chart of the buttonhole thread tension adjustment method of the sewing machine of the present invention.

[0040] In order to express the gist of the present invention clearly and clearly, the well-known technical content that is not directly related to the present invention will be omitted when describing the preferred embodiments of the present invention.

[0041] Such as Figure 4 As shown, the buttonhole stitch tension adjuster of the sewing m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap