Superconductive conductor, permanent magnet and turbine composite bearing

A turbo compound and permanent magnet technology, applied in the direction of bearings, shafts and bearings, mechanical equipment, etc., can solve the problems of parts manufacturing and assembly errors, affecting running accuracy and stability, loss, etc., to improve suspension force and running rigidity , Improve the running accuracy and stability, and enhance the effect of bearing dynamic load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

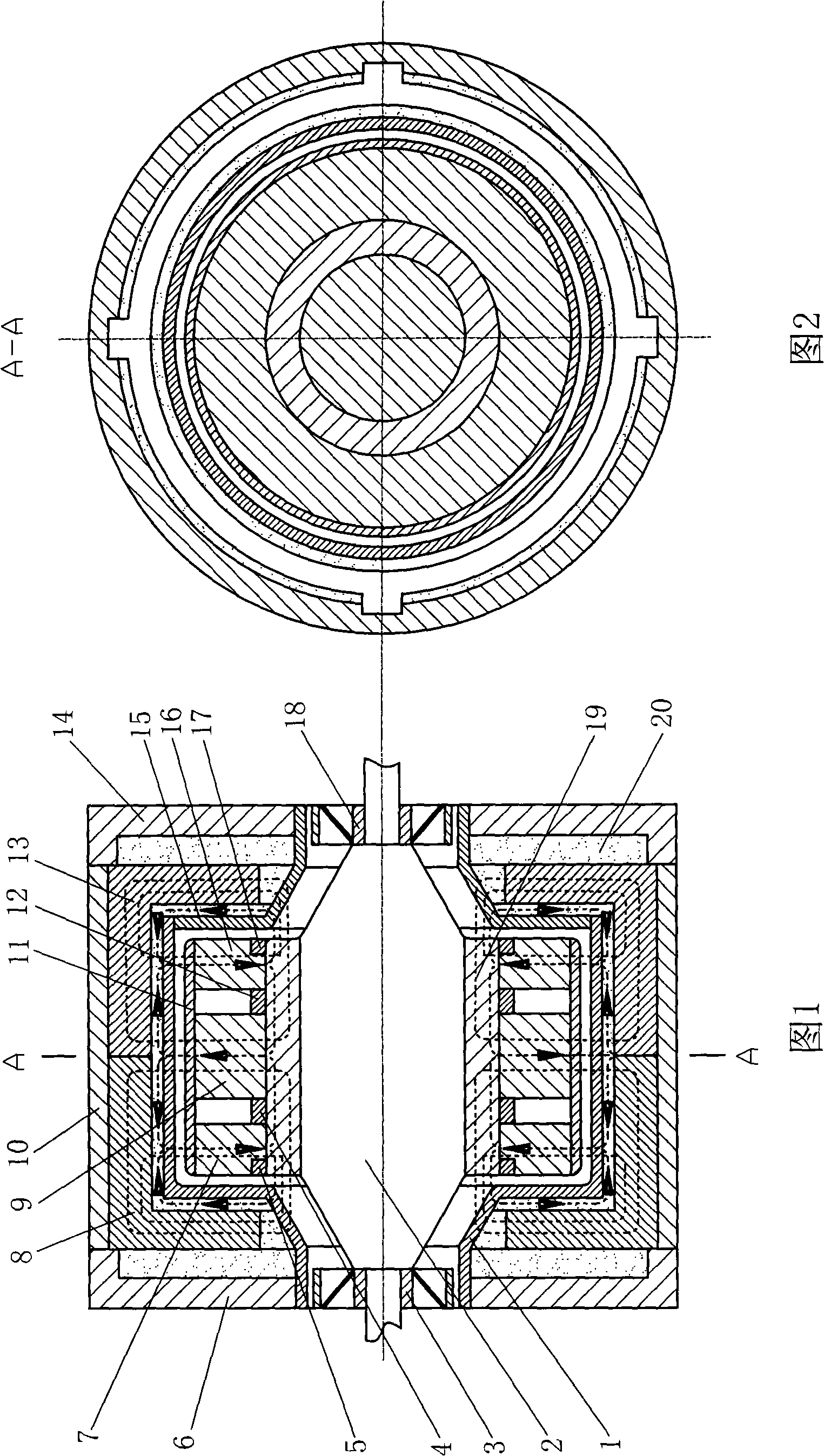

[0016] Embodiment 1: As shown in Figures 1 and 2, the bearing of this embodiment is composed of a stator and a rotor. The stator is composed of cylindrical high-temperature superconductors 8 and 13, non-magnetic insulation discs 6 and 14, non-magnetic insulation inner shells 1 and 15 and non-magnetic insulation cylinder 10-cylindrical high-temperature superconductors 8 and 13 are buttted along the axial direction. Fixed on the inner circle of the non-magnetic heat-insulating cylinder 10, and using the radial protrusions on the outer circle (shown in Figure 2) for circumferential positioning, the non-magnetic heat-insulating discs 6 and 14 are fixed on the cylindrical high-temperature superconductors 8 and 13 And the two ends of the non-magnetic heat-preserving cylinder 10, the non-magnetic heat-preserving inner shells 1 and 15 are fixed on the inner walls of the middle holes of the non-magnetic heat-preserving discs 6 and 14, respectively, and the largest outer circle of the non-m...

Embodiment 2

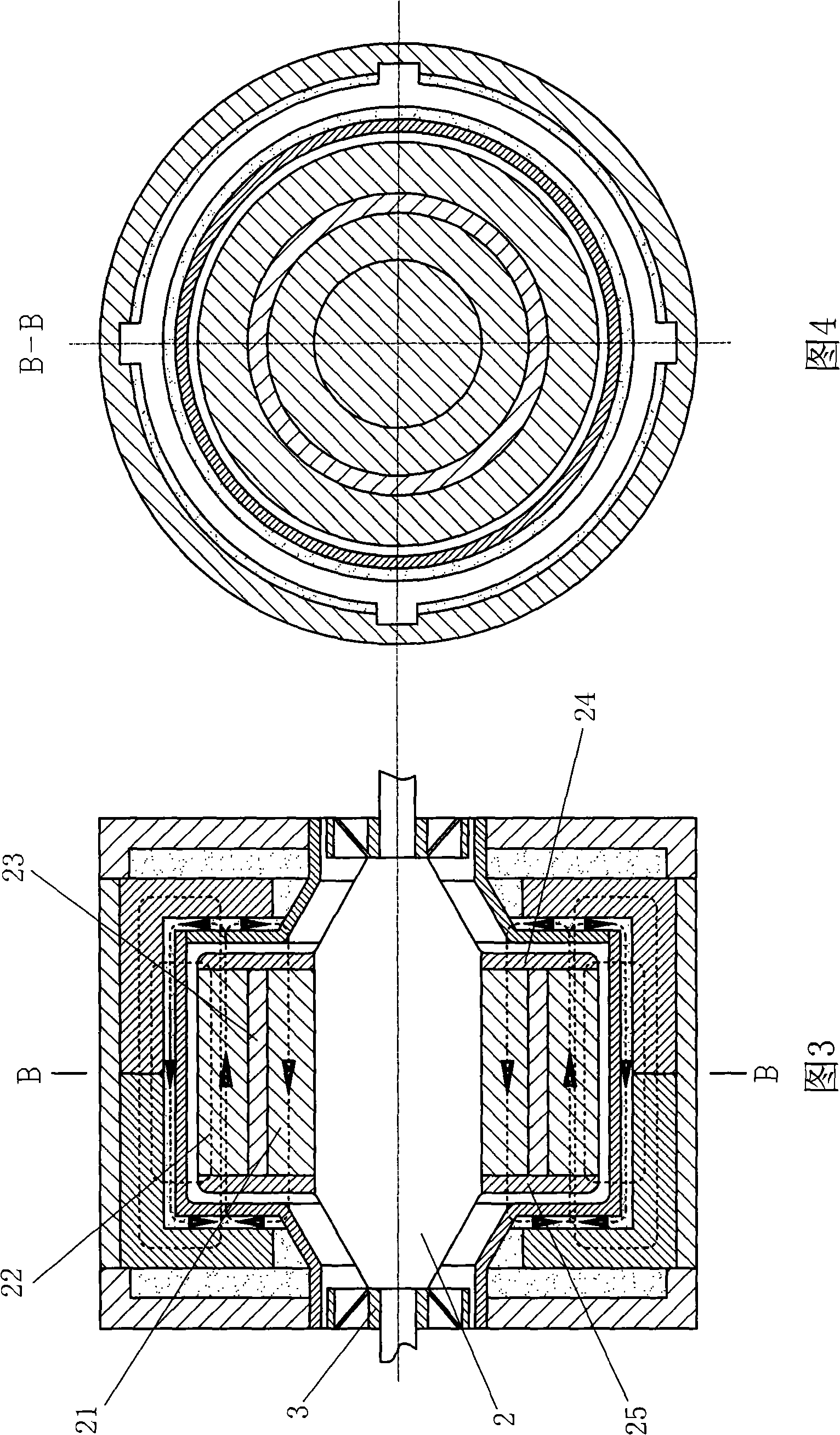

[0020] Embodiment 2: As shown in Figures 3 and 4, the bearing of this embodiment consists of a stator and a rotor. The composition of the stator is the same as that of the first embodiment. The rotor is composed of ring-shaped permanent magnets 21 and 22, non-magnetic ring 23, non-magnetic disks 24 and 25, non-magnetic shaft 2 and turbine 3 and 18 that are magnetized in the axial direction-ring-shaped permanent magnet 21 fixed sleeve On the largest outer circle of the non-magnetic rotating shaft 2, the non-magnetic ring 23 is fixedly sleeved on the outer circle of the annular permanent magnet 21, the annular permanent magnet 22 is fixedly sleeved on the outer circle of the non-magnetic annular ring 23, and the annular permanent The direction of the axial magnetic field lines in the magnet 21 is opposite to that of the annular permanent magnet 22. The non-magnetic discs 24 and 25 are also fixed on the largest outer circle of the non-magnetic rotating shaft 2, and their end faces ar...

Embodiment 3

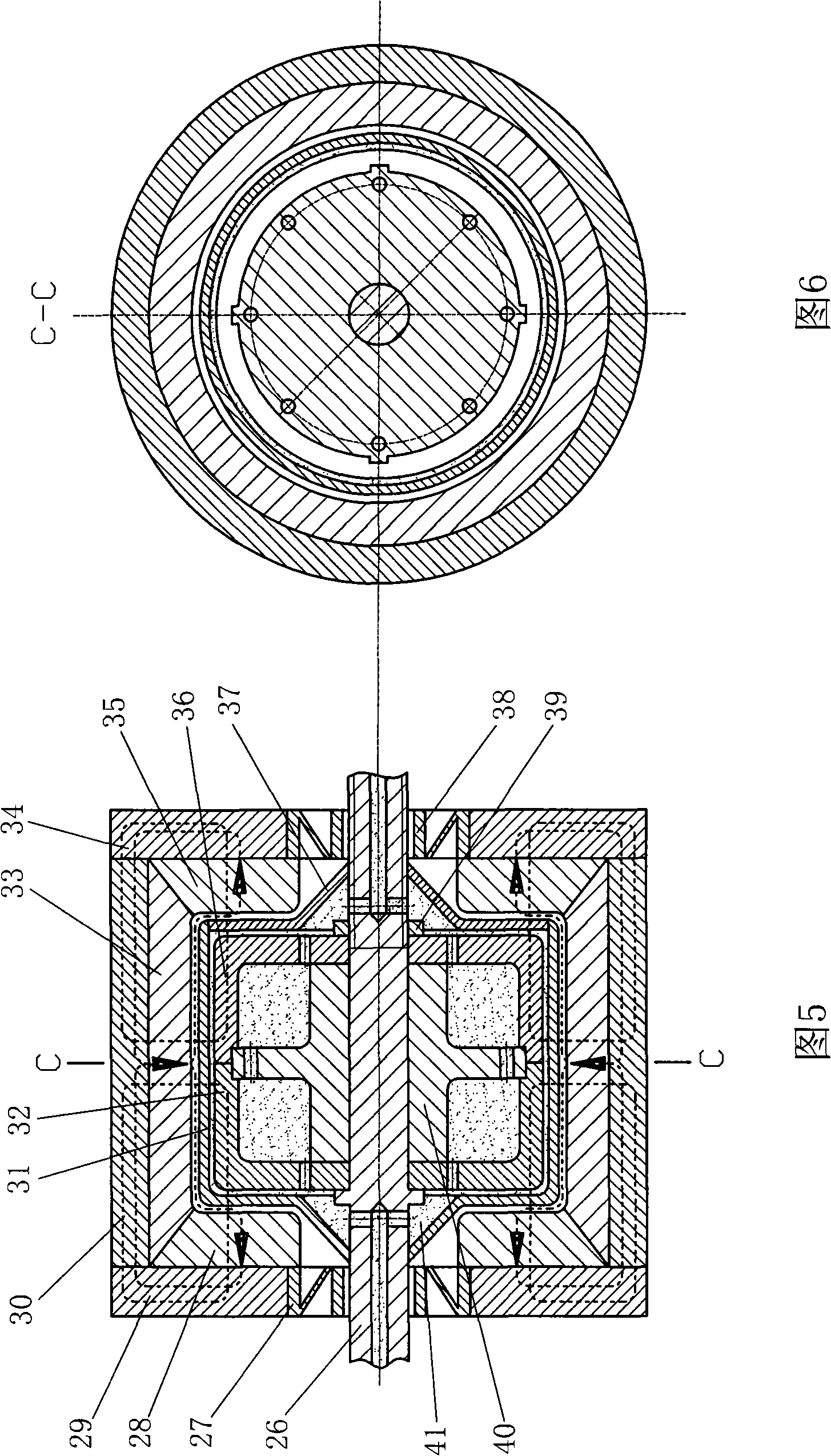

[0021] Embodiment 3: As shown in Figures 5 to 6, the bearing of the embodiment consists of a stator and a rotor. The stator is composed of a non-magnetic shaft 26, a bracket 40, cylindrical high-temperature superconductors 32 and 36, and a non-magnetic thermal insulation inner shell 31 and 37-the bracket 40, a non-magnetic thermal insulation inner shell 31 and 37 and the non-magnetic shaft 26 are solidified, non-magnetic The largest outer circle of the thermal insulation inner shell 37 is consolidated on the right end of the largest inner circle of the non-magnetic thermal insulation inner shell 31, the middle holes of the cylindrical high-temperature superconductors 32 and 36 are sleeved on the outer circle of the non-magnetic rotating shaft 26, and the cylindrical high-temperature superconductor 32 The groove of the inner cylinder wall of and 36 is caught in the protrusion of the largest outer circle of the bracket 40, so as to be circumferentially positioned. The part number 39...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com