Standard lid group used for batteries and capacitors

A capacitor and standard technology, applied in the field of battery cover packs, can solve the problems of low output, unbalanced stress, large space occupation, etc., and achieve the effect of reducing cost, high air tightness, and small space occupation

Active Publication Date: 2008-10-15

CHAOZHOU THREE CIRCLE GRP

View PDF2 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, due to the thinner (less than 1.5 mm) and large diameter (up to 35 mm) of the large-diameter cover group, it is easy to deform and warp when subjected to high temperature and glass sintering, resulting in unbalanced stress during welding, which is easy to use There is a hidden danger of air leakage in the packaged battery cover group

In addition, corresponding sintering fixtures must be used for various cover groups, especially large-sized cover groups occupy a large space during sintering, the efficiency of the sintering fixture is low, the energy consumption is large, the output per unit time is low, and the product reliability is poor

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Login to View More

Abstract

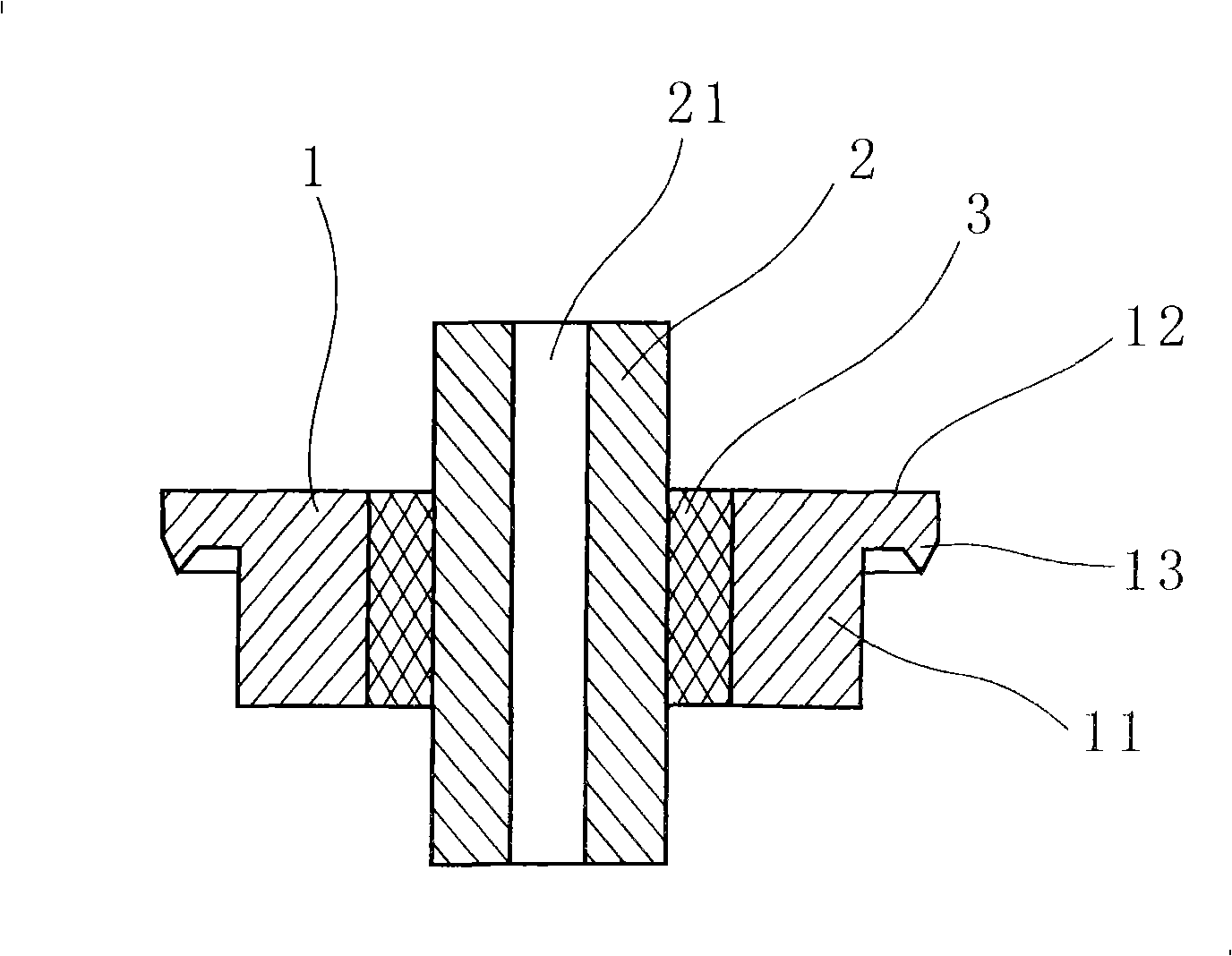

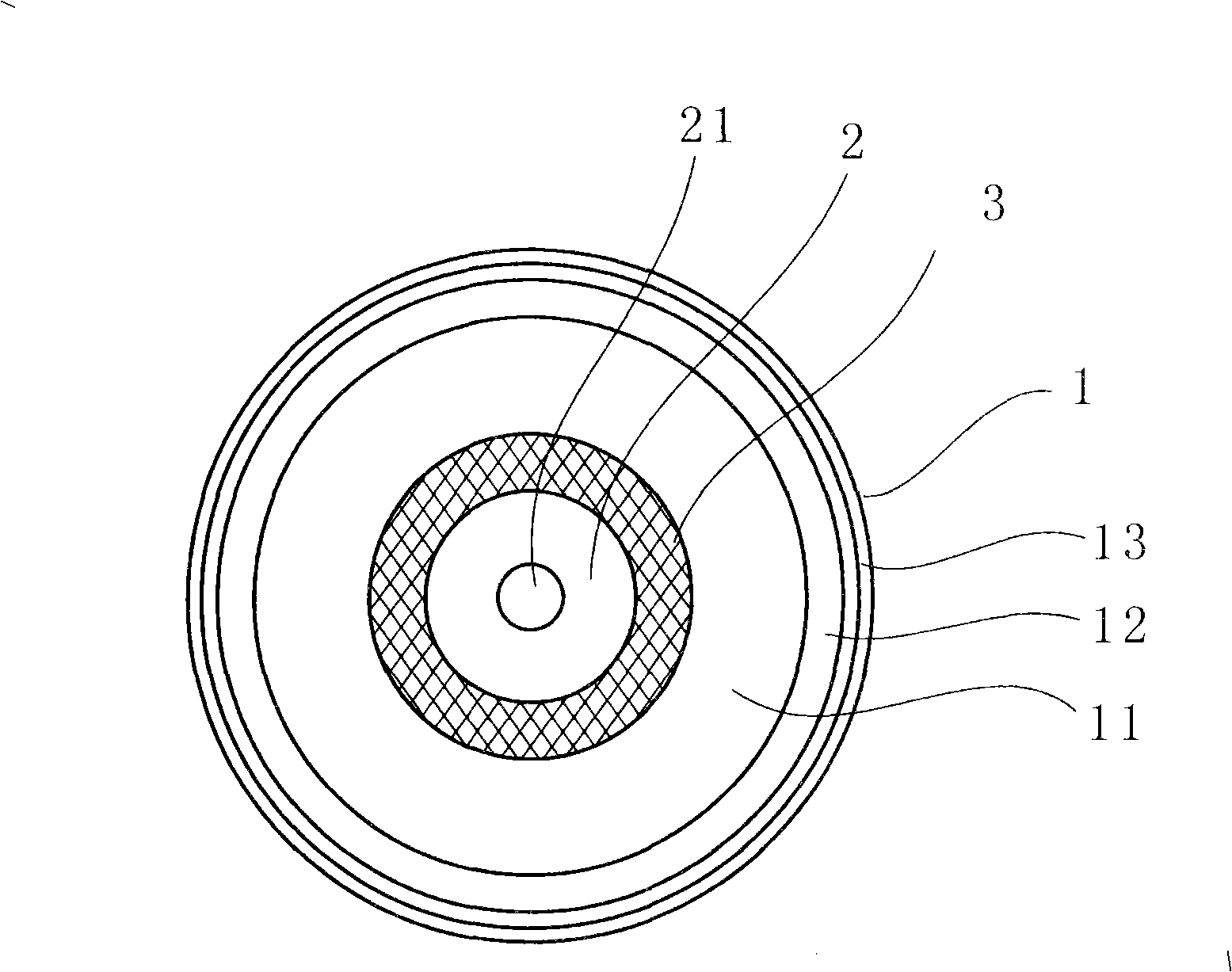

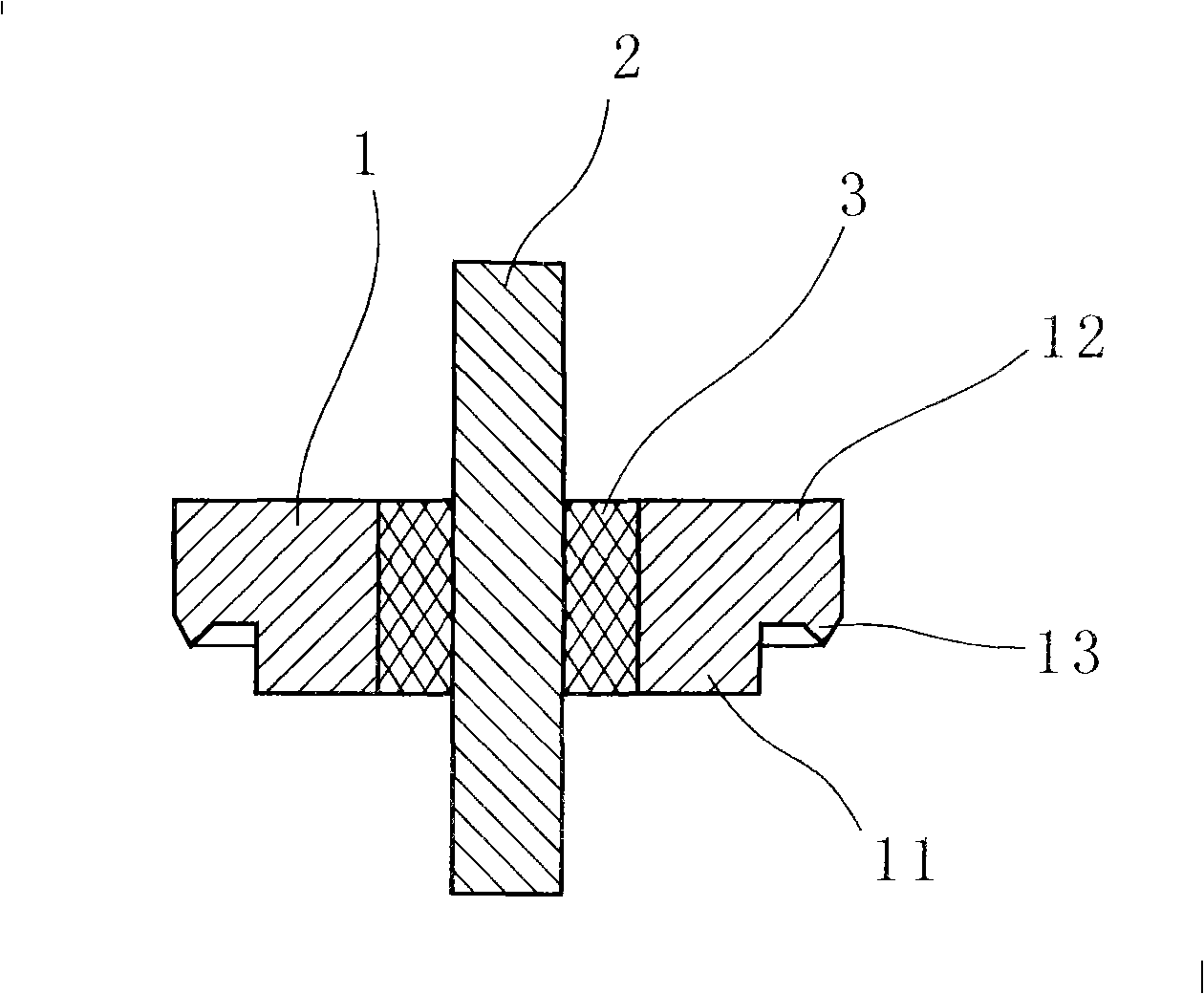

The invention relates to a standard cover group used for a battery or a capacitance, which includes a cover body and an electrode, furthermore, the electrode and the cover body are sealed and connected by glass insulation; the cover body comprises a cylindrical cover core and a broad shoulder which is coaxial with the cover core, the broad shoulder and an upper end surface of the cover core are the same whole, and a ring-shaped flange is arranged below the edge of the broad shoulder. The standard cover group which realizes the invention can be pressure-welded with various batteries or capacitances with different sizes by resistance welding to form an integral cover group, thus meeting the requirement that the cover plates of the batteries or capacitances with different specifications can be satisfied by using only one standard cove group; furthermore, as the standard cover group has comparatively large thickness, deformation and warpage phenomena can not be generated by high-temperature sintering, and as the cove plate needs not to go though high temperature, planeness can be kept during stamping, steam leakage of the cover group cannot be caused by the warpage during welding and sealing, thus the cover group has the advantages of higher strength and air tightness; as the diameter of the standard cover group is small, sintering fixtures can be universally used, furthermore, the standard cover group occupies small space, has high efficiency and low energy-consumption, and can effectively reduce the cost.

Description

A standard cover assembly for batteries or capacitors Technical field The invention relates to a glass-sealed battery cover group, in particular to a standard cover group for batteries or capacitors. technical background For the battery cover used in high-end lithium-ion batteries, glass packaging technology is currently the best production method. First, the electrodes, encapsulated glass parts and metal shell are assembled into a semi-finished battery cover with electrodes, and then the battery with electrodes The semi-finished product of the cover assembly and the sintering fixture are put into the sintering furnace, and the battery cover component is made through certain process steps. This part is used in high-end batteries due to its special performance, such as aerospace, military and other fields. However, because the thickness of the large-diameter cover group is thin (can be less than 1.5 mm) and the diameter is large (up to 35 mm), it is extremely easy to deform and w...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01M2/04H01M2/06H01G2/10H01G4/224H01G4/228H05K5/03H01M50/147H01M50/172

CPCY02E60/10

Inventor 陈绍鸿

Owner CHAOZHOU THREE CIRCLE GRP

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com