Cutting head

A technology of cutter head and body, applied in the field of cutting cutter head, can solve the problems of poor strength and wear resistance of the cutter head material, easy damage of the cutter head, and increase the burden on the enterprise, so as to achieve long service life, not easy to be damaged, and extended service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

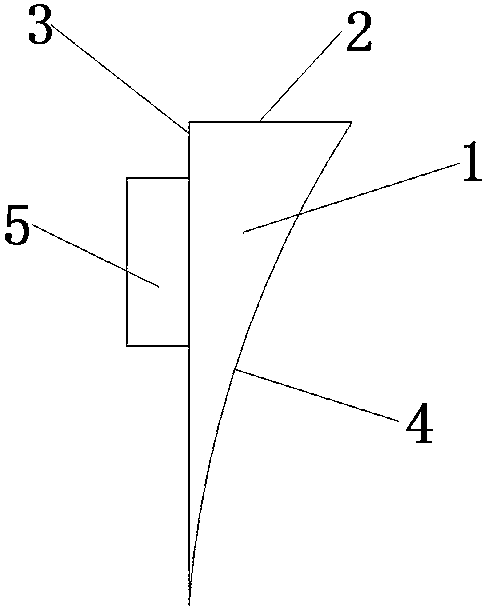

[0011] Such as figure 1 As shown, a cutting bit, a cutting bit, includes a bit body 1 and a side buffer pad 5, the bit body 1 includes a top edge 2, and a side is respectively connected to both sides of the top edge 2. The two sides include a straight side 3 and an arc-shaped side 4, the bottom of the straight side 3 is connected with the bottom of the arc-shaped side 4, and the outer edge of the straight side 3 of the cutter head body 1 is connected with a side The buffer pad 5, the cutter head body 1 is made of tungsten-titanium-cobalt cemented carbide. The tungsten-titanium-cobalt cemented carbide is YT05 / YT30 tungsten-titanium-cobalt cemented carbide. Side buffer pad 5 adopts rubber material to make.

[0012] The cutter head body 1 of the present invention is made of tungsten-titanium-cobalt cemented carbide, which has high strength and high wear resistance, lon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com