Conveyer belt of substrate material

A technology for conveyor belts and substrates, applied in the direction of photosensitive materials, thin material processing, conveyor objects, etc., can solve problems such as damage and damage, and achieve the effect of preventing swing, preventing offset and excellent yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

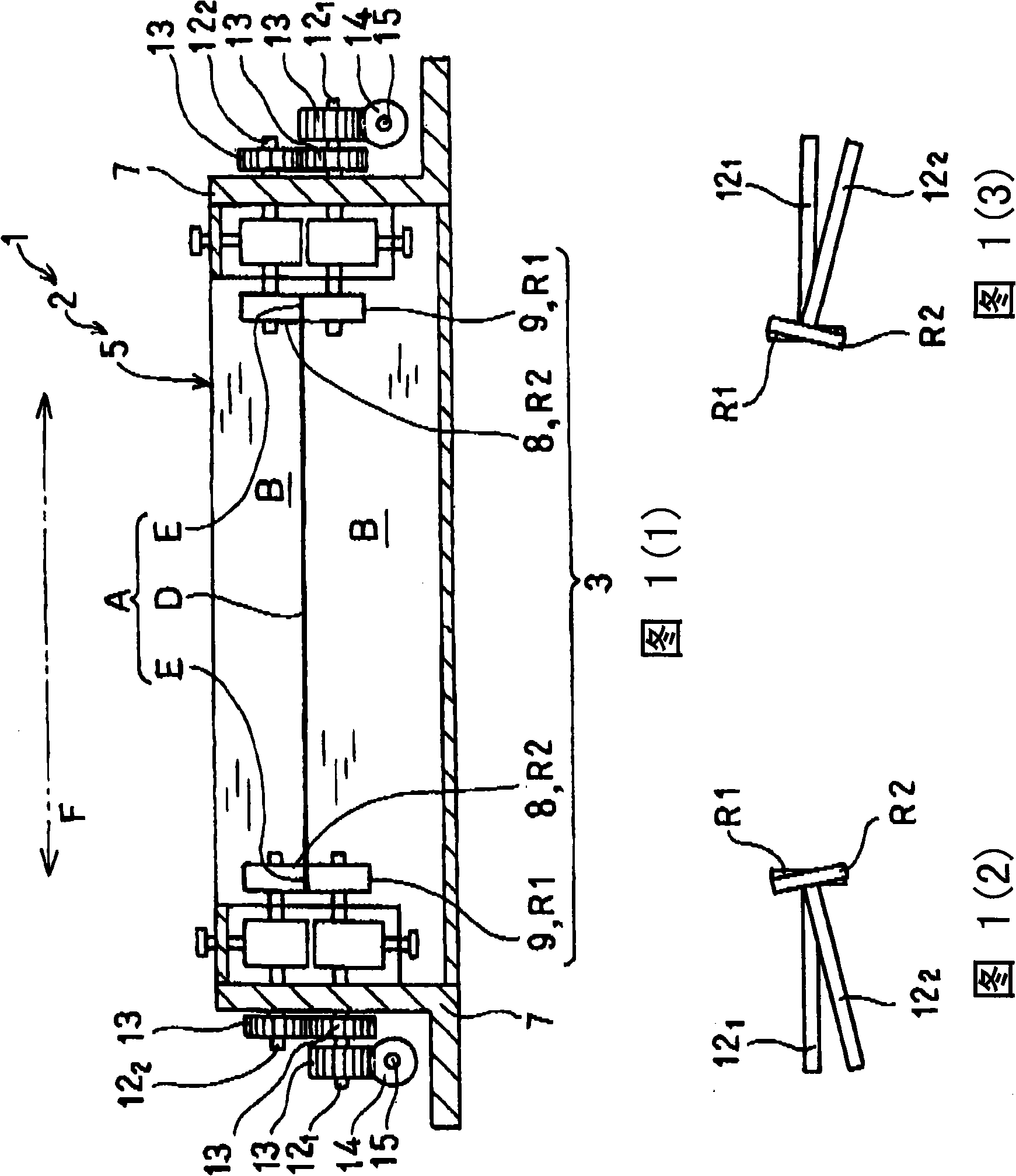

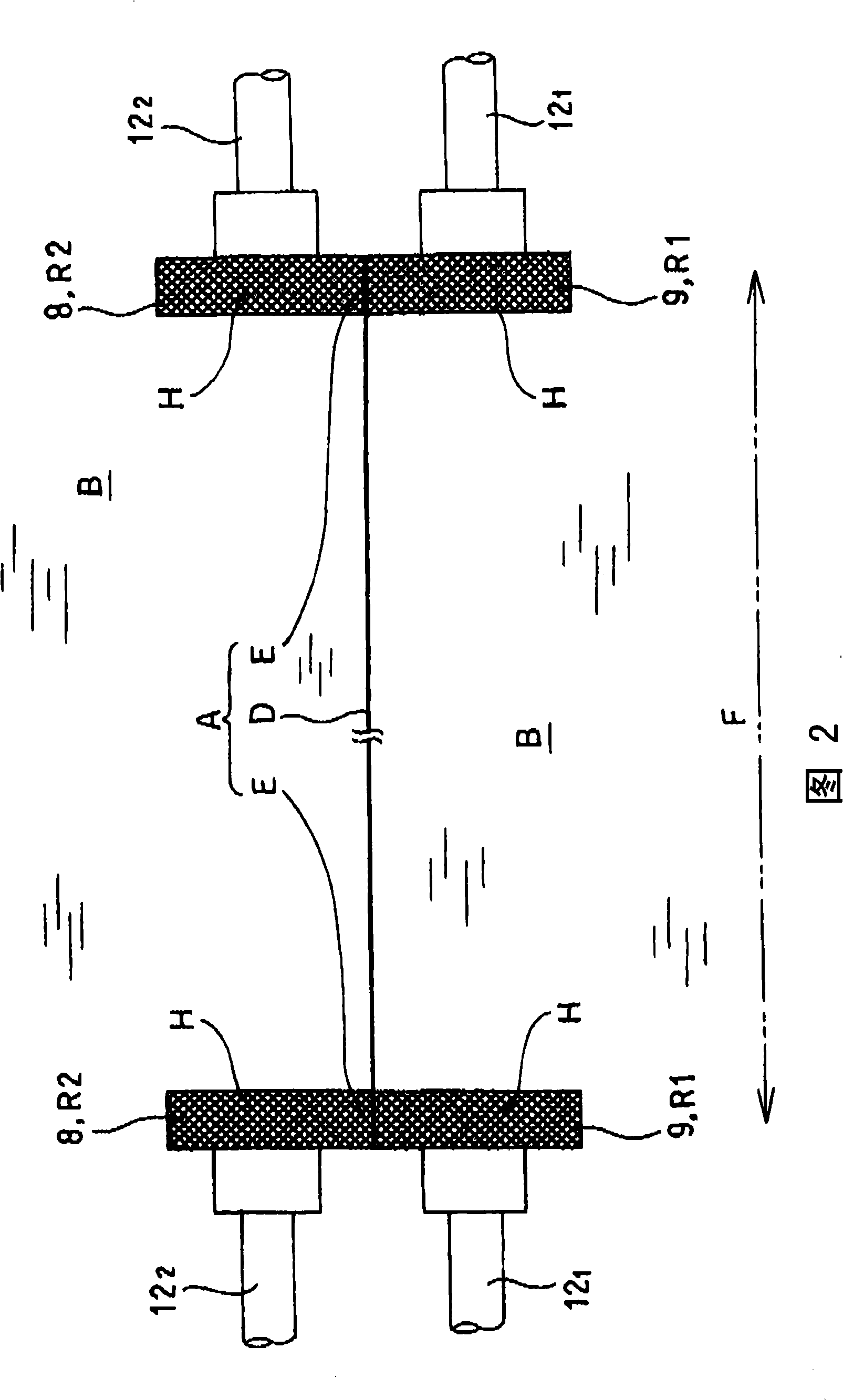

[0053] Next, the conveyer of the substrate material of this invention is demonstrated concretely based on the preferable form for implementing the invention shown in figure.

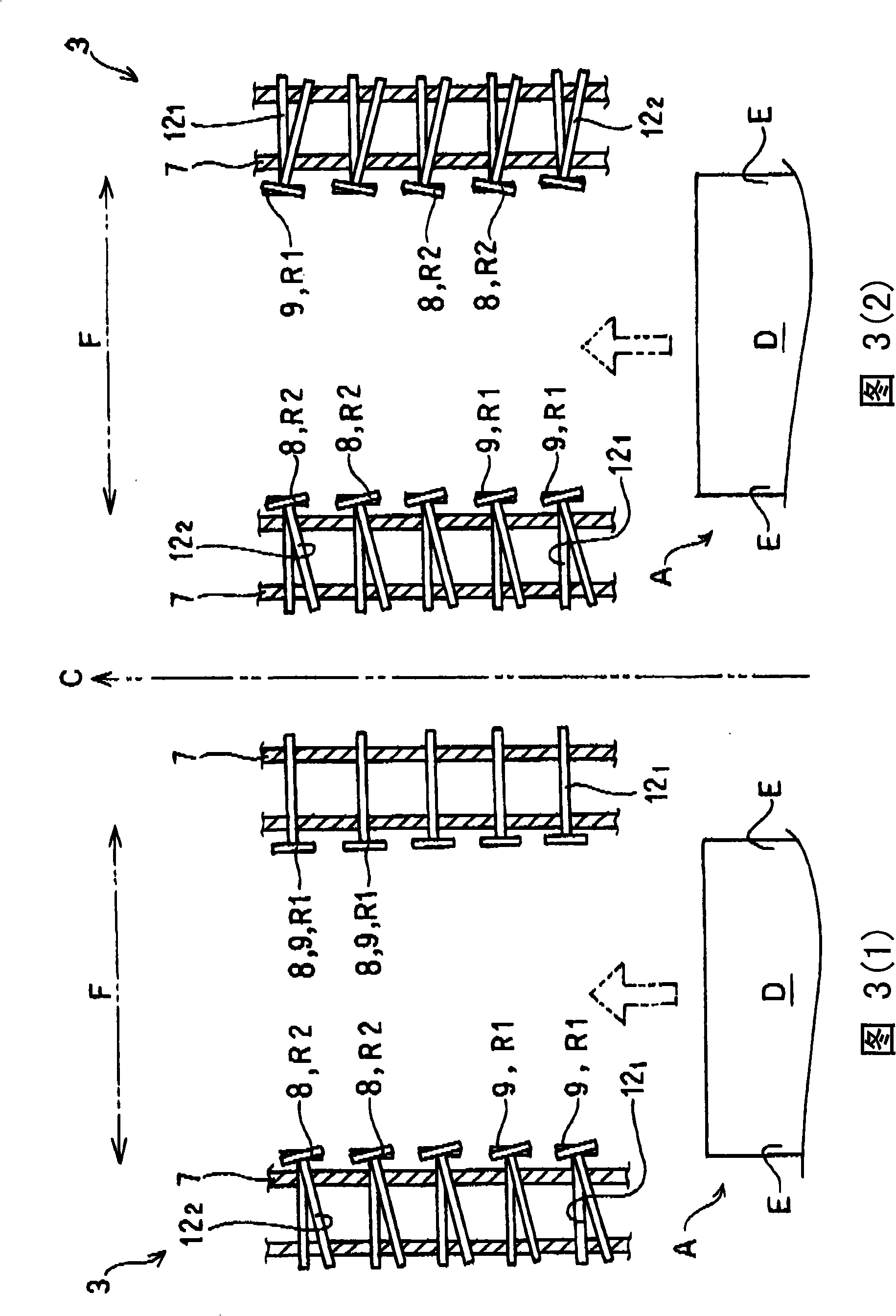

[0054] 1(1) to 1(3), FIG. 2, and FIG. 3(1) to 3(2) are used to illustrate preferred forms of the present invention. In addition, FIG. 1 (1) is an overall front sectional view, FIG. 1 (2) is a plan explanatory view of the left end surface conveying roller, and FIG. 1 (3) is a plan explanatory view of the right end surface conveying roller. Fig. 2 is an enlarged view of the main part of Fig. 1(1).

[0055] 3(1) to 3(2) are plan explanatory views of the combination mode of the end surface conveying rollers. FIG. 3(1) shows the main part of one example, and FIG. 3(2) shows the main part of another example. Figure 4 It is an explanatory diagram of the overall side view section.

[0056] (About circuit board)

[0057] The surface treatment apparatus 1 of the present invention is used in a manufacturing proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com