Anti-crack, noise-insulation and heat-preservation plastering material for inner wall

A kind of gray material and interior wall technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as poor insulation, wall cracks, and poor sound insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The invention is easy to implement and is an ideal material to replace traditional plastering materials. It can not only prevent cracking, but also contains polystyrene particles and plant fibers, which is light in weight, heat-retaining, and has good sound insulation effect. Features that the material does not have. The present invention requires comminuted mixing during preparation, and requires that the water content and soil content of the sand should be less than 0.3%, and the rest of the raw materials should be kept dry.

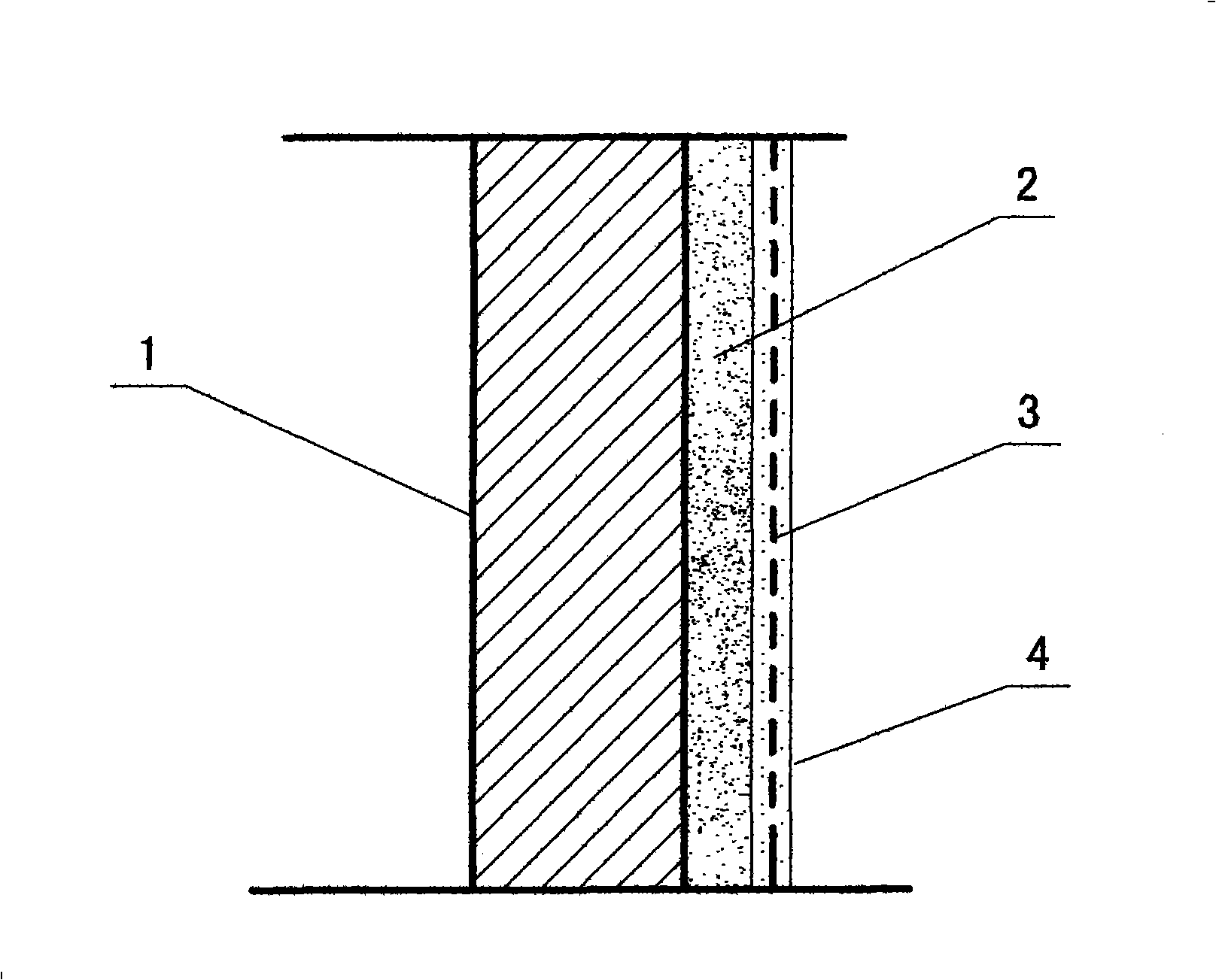

[0019] The construction process of the material of the present invention is carried out as shown in the accompanying drawings, first smear a 10-30mm thick bottom ash 2 on the wall surface 1, then hang a glass fiber net 3, and then wipe the second-layer ash 4, and its thickness is generally 5-30 mm. 10mm.

[0020] The bottom ash formula in the present invention is slightly adjusted as follows, that is, after increasing the amount of polyphenylen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com