Layer-by-layer speed regulating device for spinning frame

A technology of speed control device and servo motor, applied in textiles and papermaking, etc., can solve the problem of inability to achieve the effect, does not solve the change of the tension of the lifting balloon, does not consider the change of the winding radius of the ring plate and the change of the height of the balloon, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

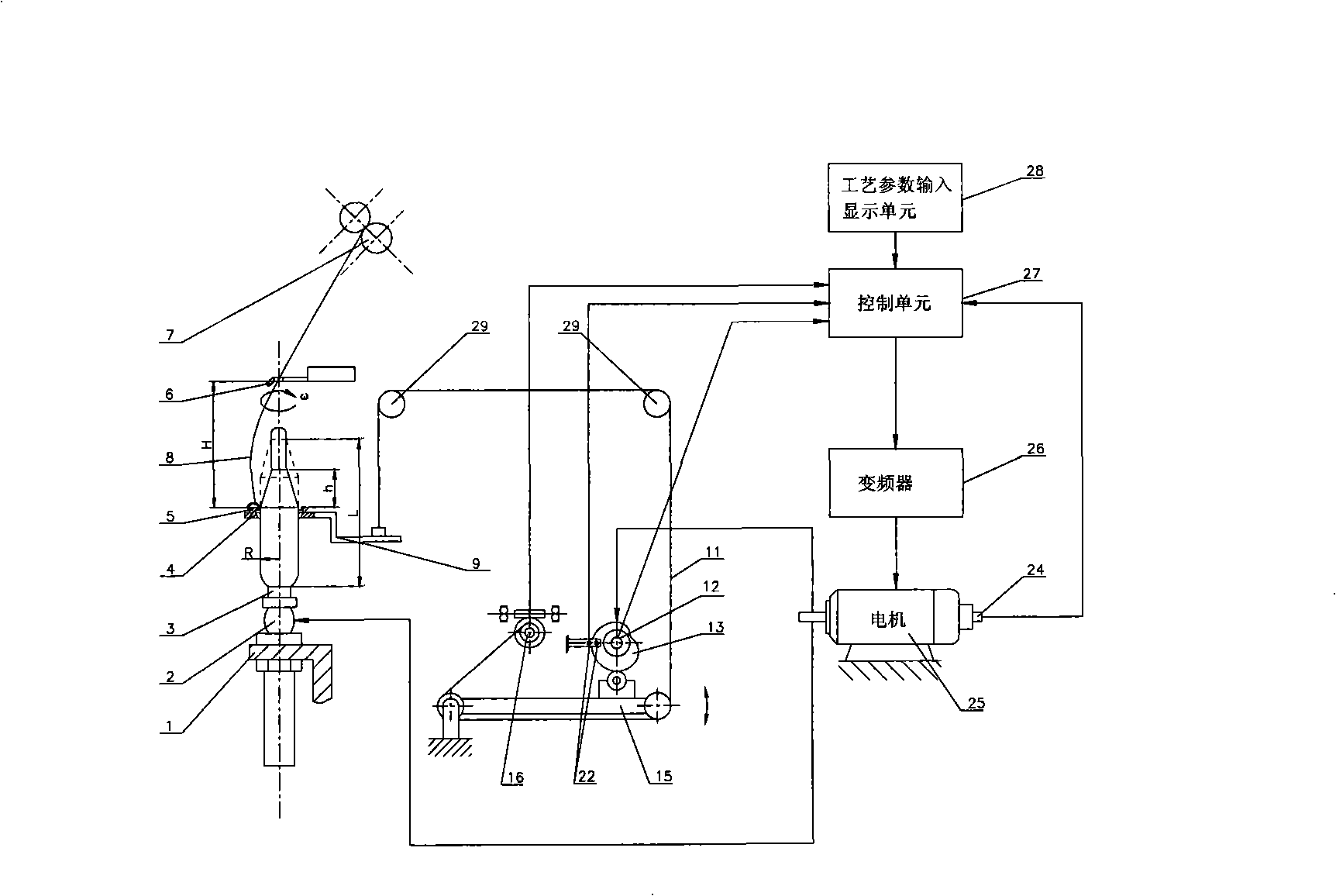

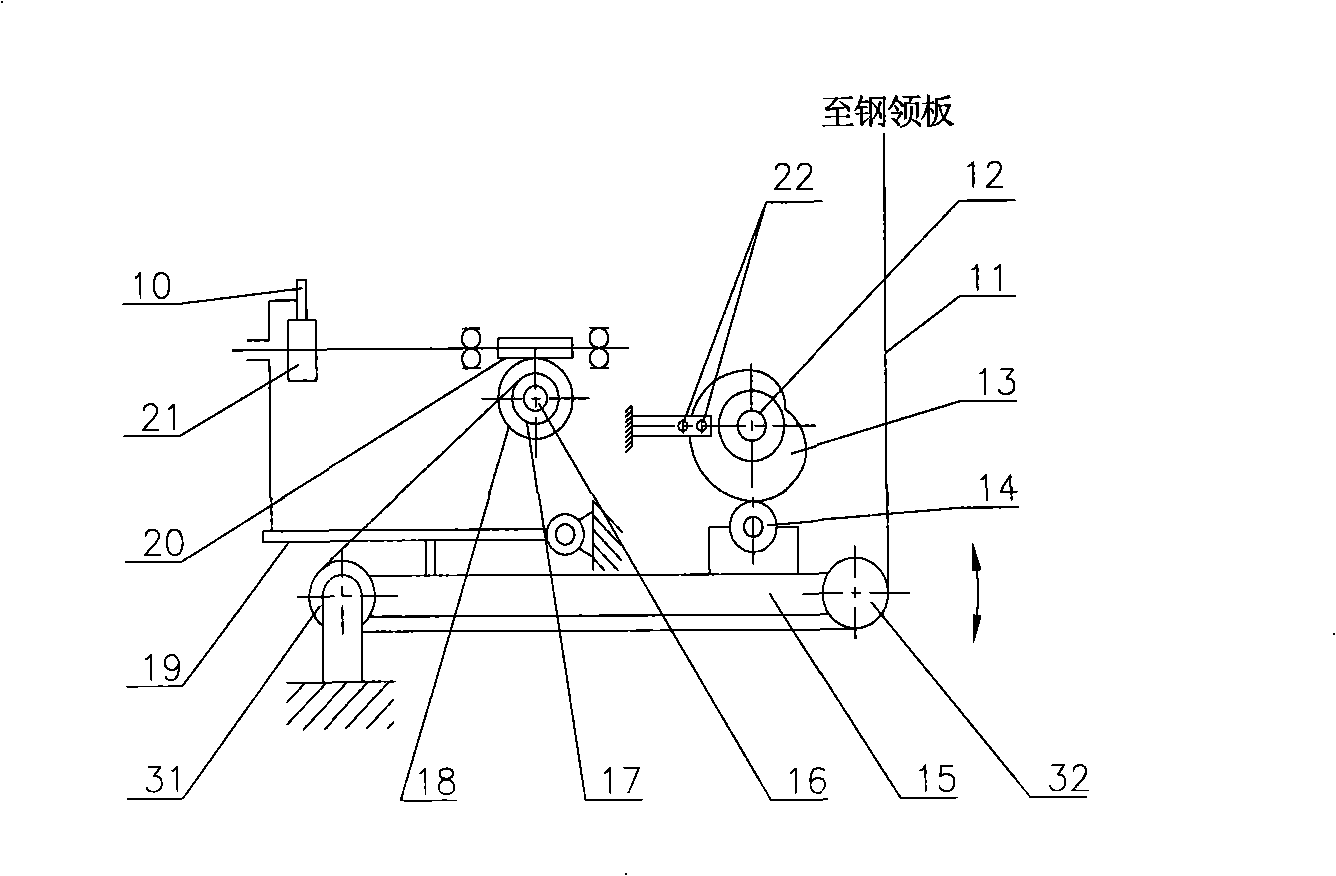

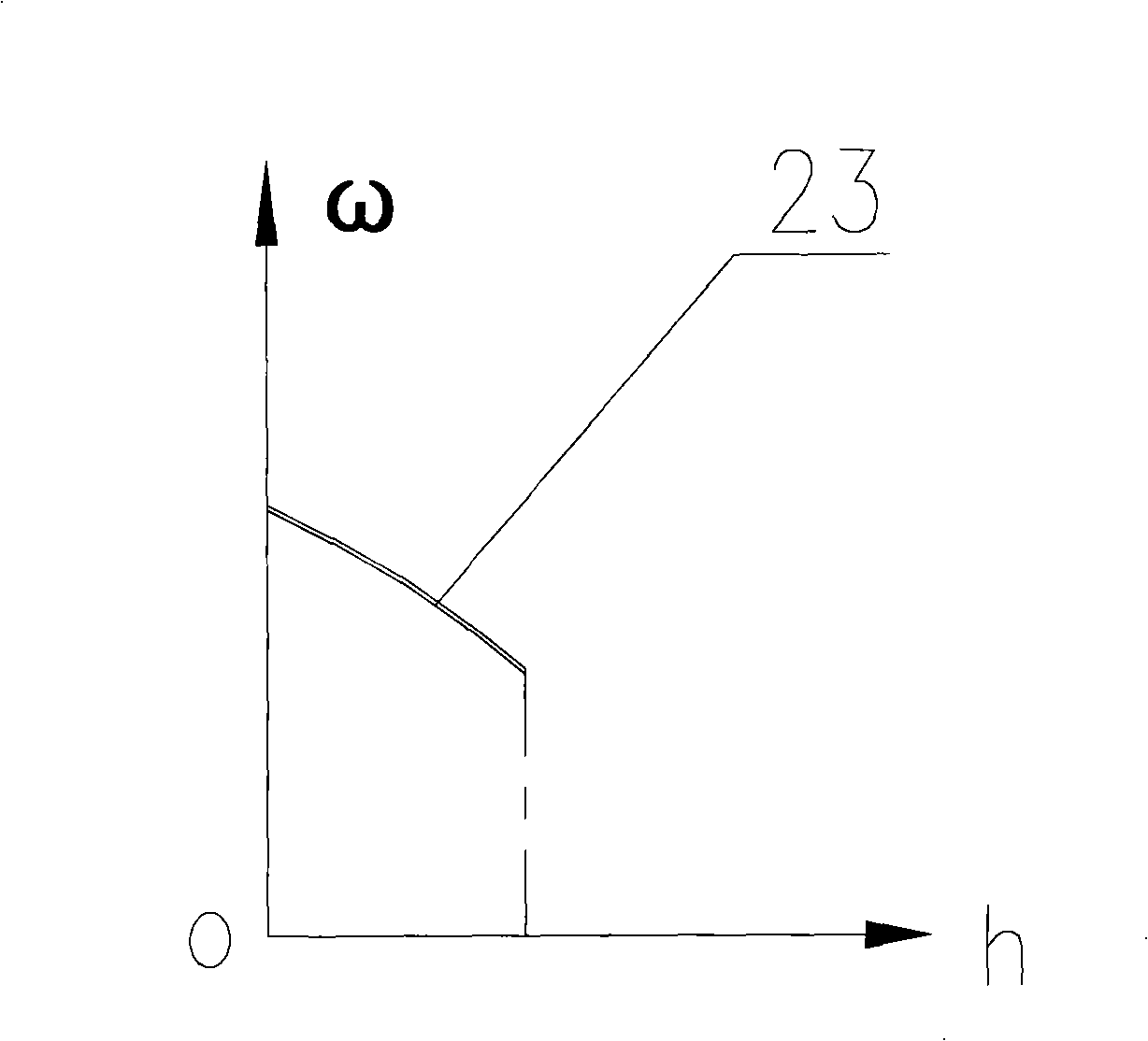

[0034] The invention adopts forming cam, lifting swing arm, traction chain, steel ring plate, ratchet pawl step-up mechanism, winding sprocket, control unit, display input unit, frequency converter, motor, encoder or sensor to form spinning frame Layer speed control device. According to different winding radii and balloon heights, the running speed of the spindle is changed, and constant tension spinning is realized by layer-by-layer speed regulation.

[0035] Firstly, input the spinning variety and process parameters into the display unit, and the control unit bases on the input parameters, the short stroke position of the ring plate lifting given by the forming cam encoder, and the step-up position of the ring plate given by the winding sprocket encoder , and according to the speed regulation curve 23 obtained by experiments or calculations, the control unit sends a control command to the frequency converter through calculation, and the frequency converter sends a frequency ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com