Laser gas concentration measurement equipment probe device

A technology of concentration measurement and laser gas, which is applied in the direction of measuring device, color/spectral characteristic measurement, material analysis through optical means, etc. It can solve problems such as impact, component change, and influence on the light intensity of light source and photosensitive device reception, etc., to achieve accurate The effect of measuring and accurate gas concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

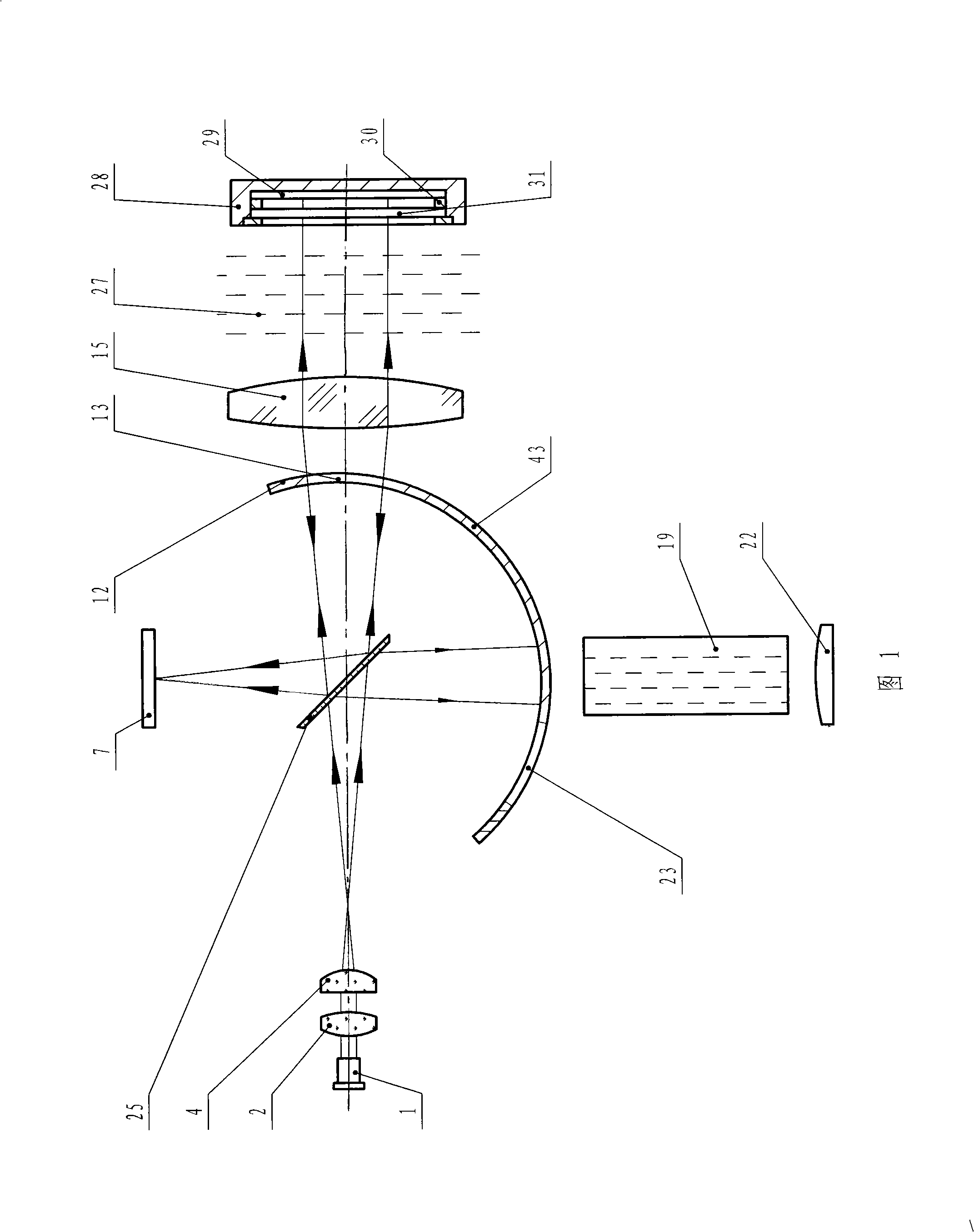

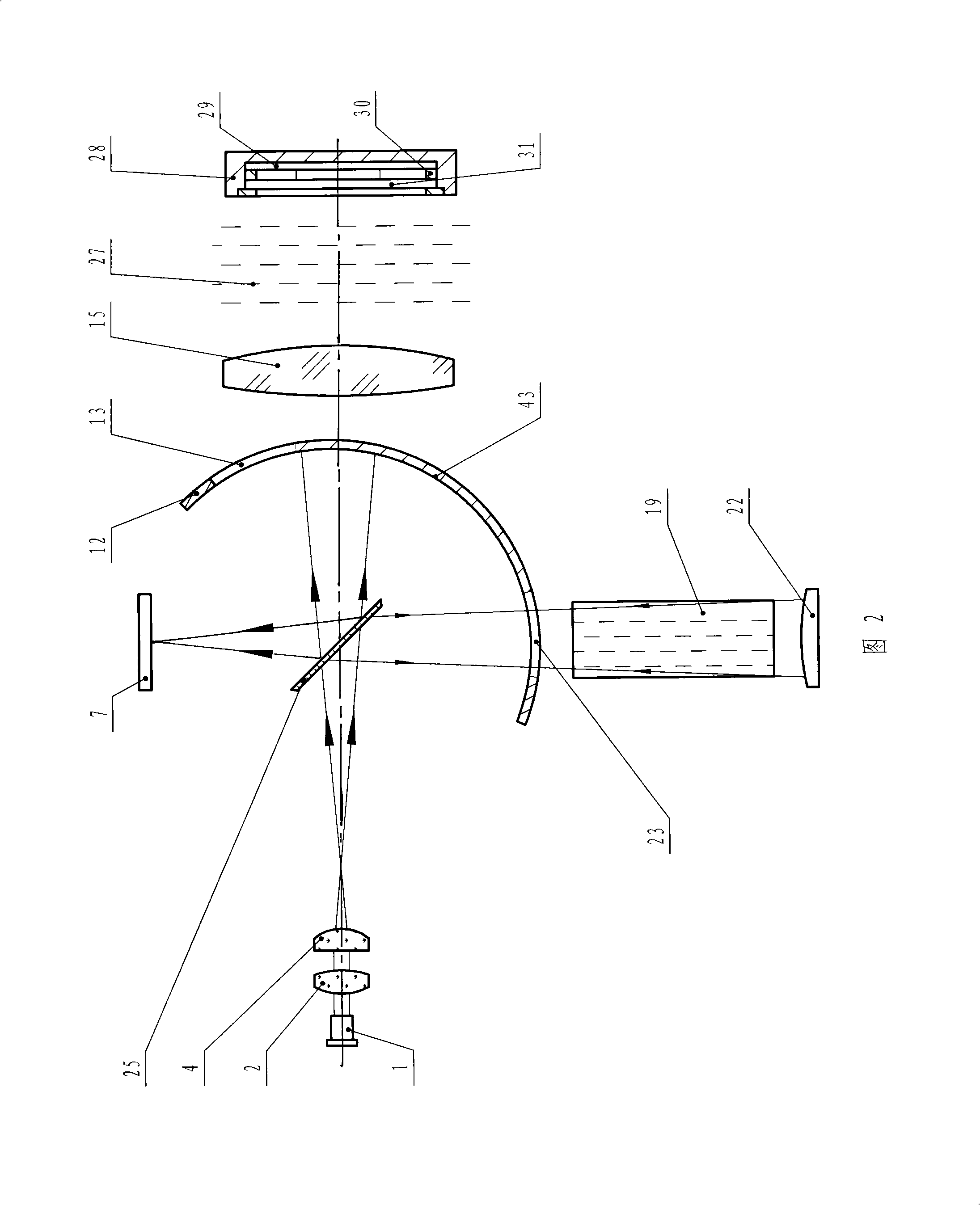

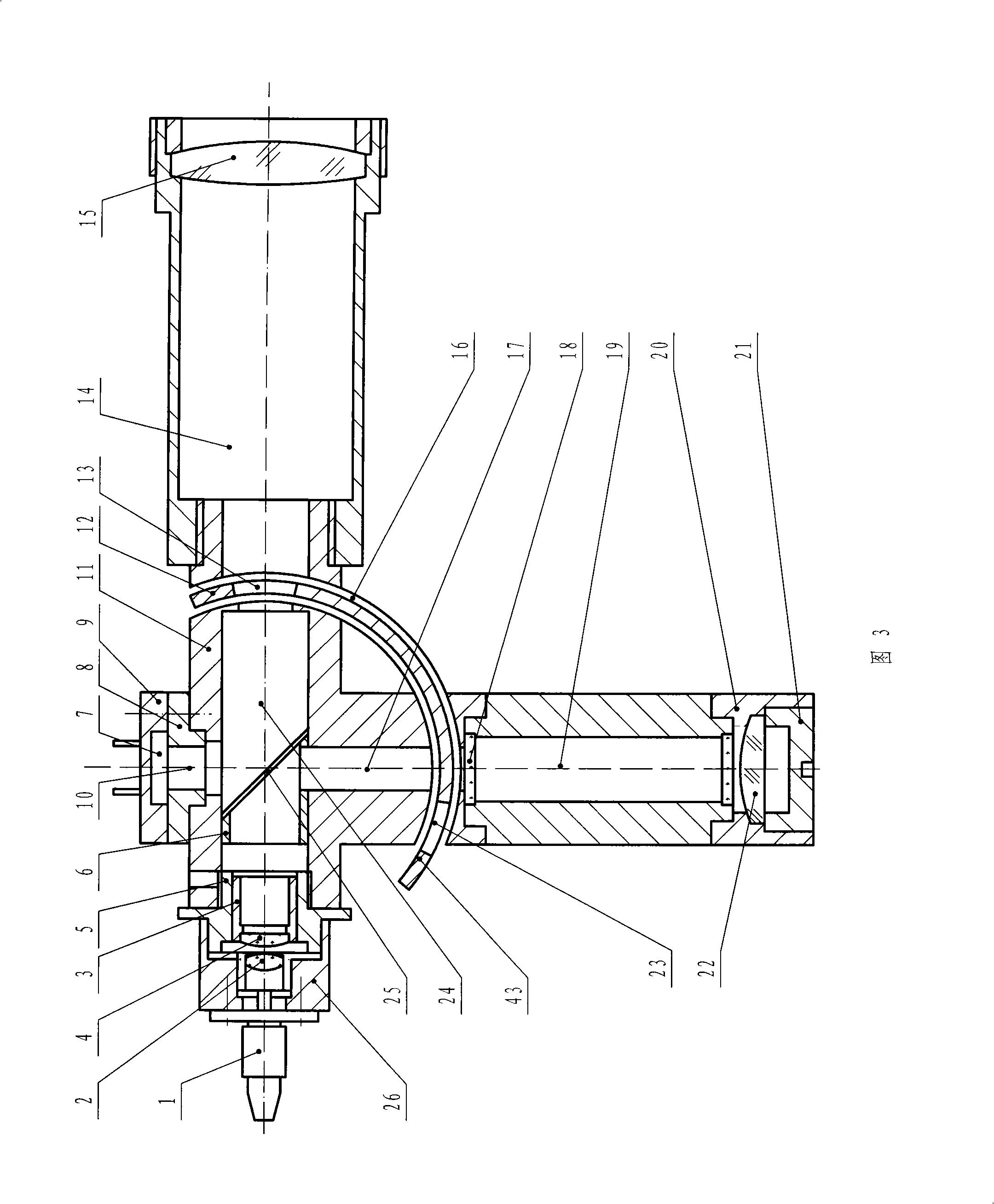

[0019] Fig. 1 is a schematic diagram of the measurement state principle of the probe device of the laser gas concentration measuring equipment of the present invention, and Fig. 2 is a schematic diagram of the calibration state principle of the probe device of the laser gas concentration measuring device of the present invention, and the laser gas concentration measurement shown in Fig. 1 and Fig. 2 The probe device of the equipment mainly includes: laser source 1, condenser lens 2, eyepiece 4, infrared photosensitive tube 7, objective lens 15, and translucent beam splitter 25. Condenser 2, eyepiece 4 and objective lens 15 are arranged in sequence, translucent beam splitter 25 is fixed between eyepiece 4 and objective lens 15, and infrared photosensitive tube 7 is arranged at the top position of translucent beam splitter 25, in described translucent beam splitter 25 and the objective lens 15 are provided with light blocking device 43, described light blocking device 43 can sele...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap