Hollow composite insulator and method of producing the same

A composite insulator, hollow technology, applied in insulators, electrical components, circuits, etc., can solve the problems affecting the electrical performance and service life of composite insulators, safety accidents, product scrapping, etc., to eliminate potential safety hazards, prolong service life, and save operations. effect of steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

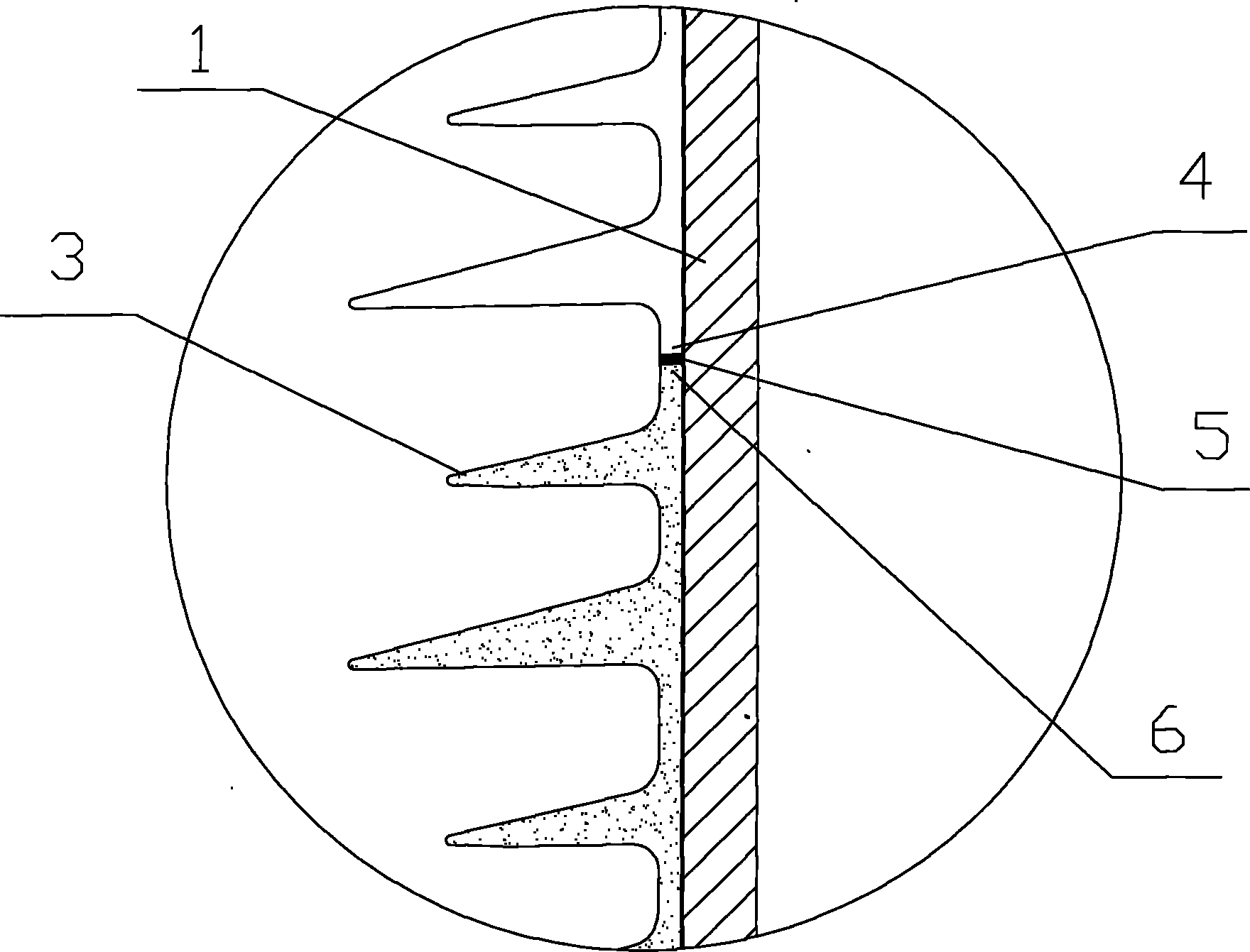

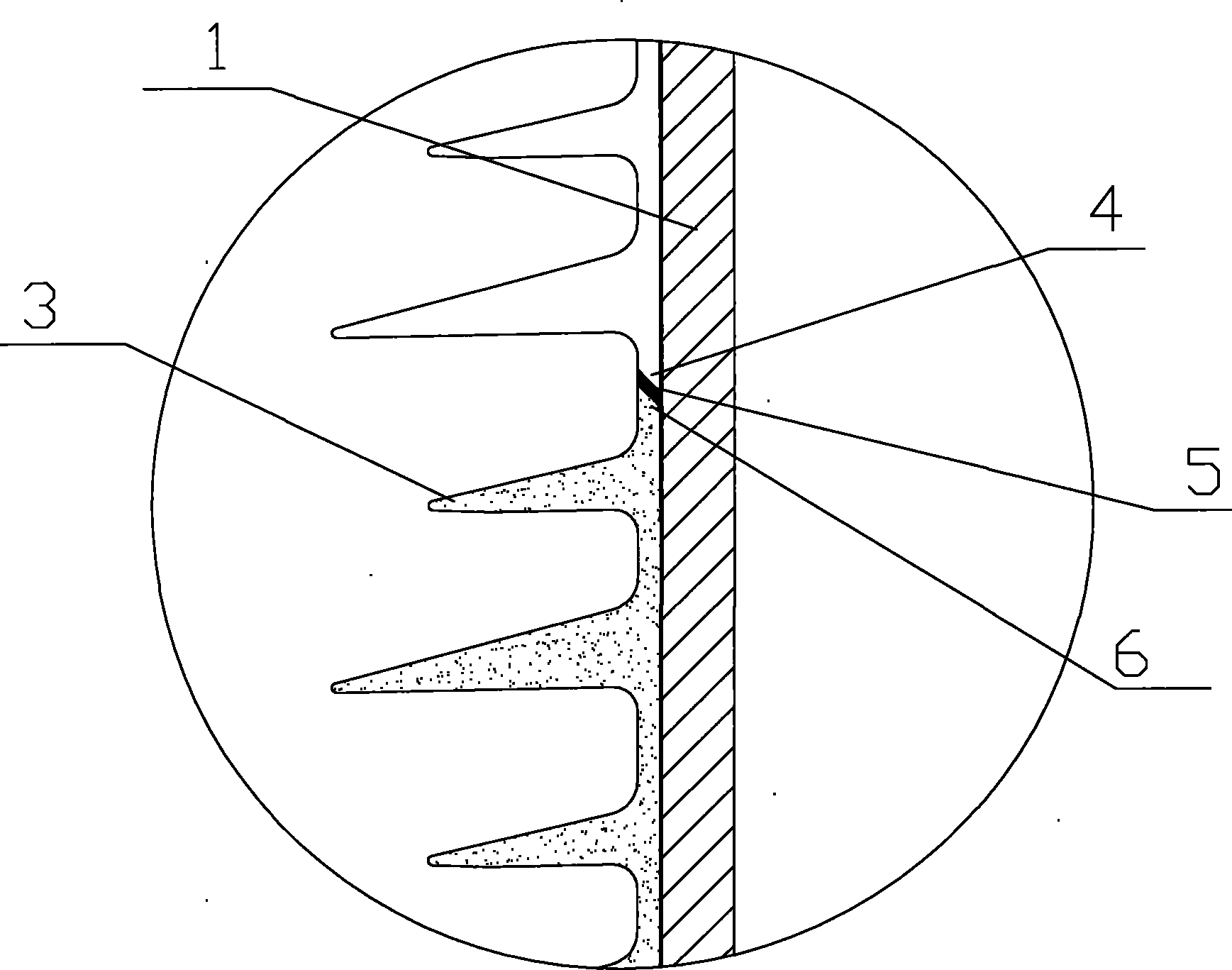

[0020] Such as figure 2 , image 3 As shown, in the prior art, the radial overlapping surface joint structure and the oblique surface overlapping joint structure are generally used, that is, the umbrella sleeve part of the previous injection molding is repaired into a straight surface or an inclined surface, and glue is applied on the straight surface or the inclined surface. Adhesive, and then directly followed by injection molding of silicone rubber to form the umbrella cover of the next mold, which is connected in sequence until the whole product is made.

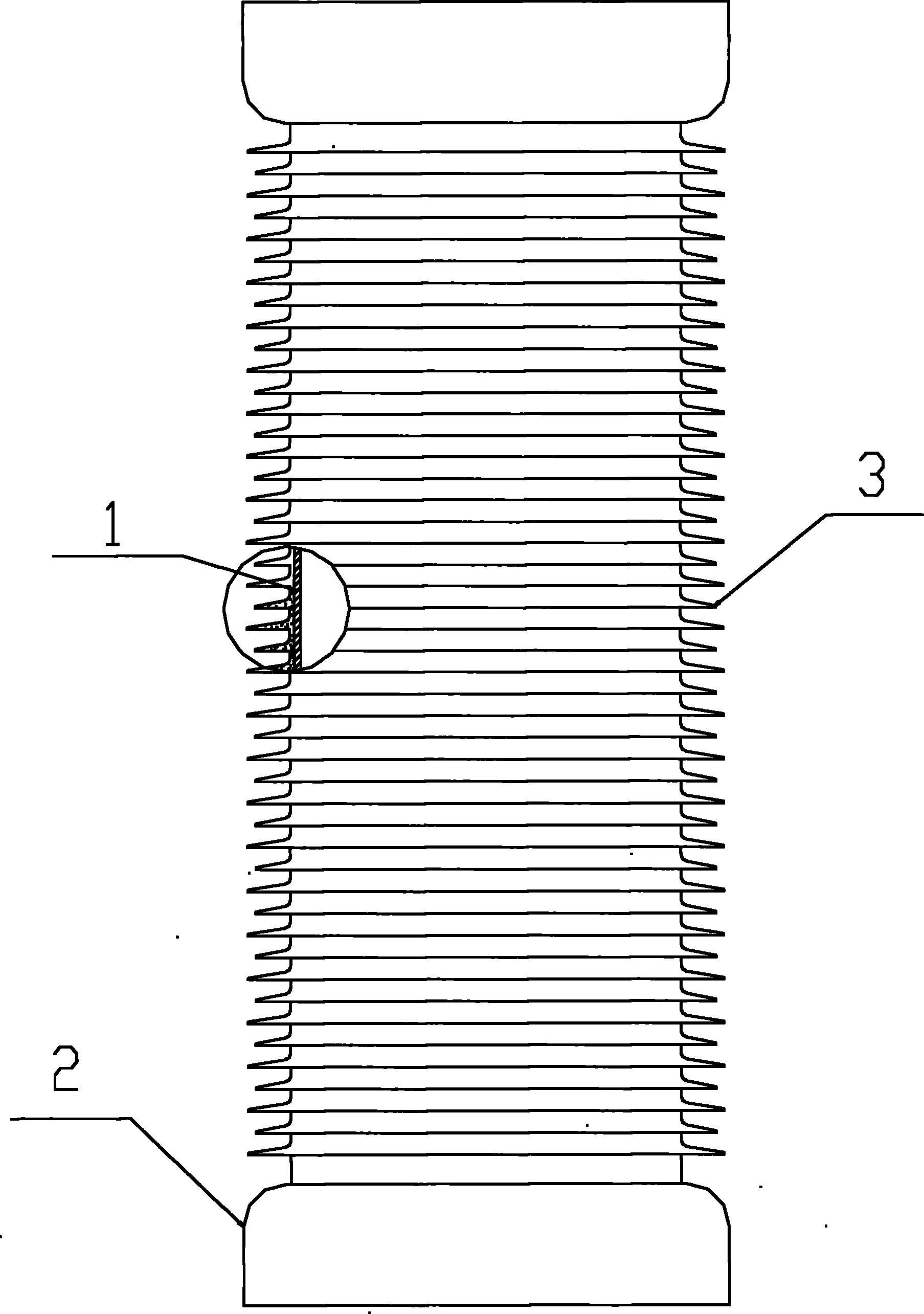

[0021] Such as figure 1 , 4 As shown, the present invention is composed of an insulating mandrel inner cylinder 1 made of glass fiber reinforced plastics, an aluminum end flange 2, and a silicone rubber umbrella cover 3. The silicone rubber umbrella cover 3 is composed of more than two silicone rubber umbrella covers that are sequentially injection molded. The connection structure between two adjacent silicone rubber...

Embodiment 2

[0024] Such as figure 2 , image 3 As shown, in the prior art, the radial overlapping surface joint structure and the oblique surface overlapping joint structure are generally used, that is, the umbrella sleeve part of the previous injection molding is repaired into a straight surface or an inclined surface, and glue is applied on the straight surface or the inclined surface. Adhesive, and then directly followed by injection molding of silicone rubber to form the umbrella cover of the next mold, which is connected in sequence until the whole product is made.

[0025] Such as figure 1 , 4 As shown, the present invention is composed of an insulating mandrel inner cylinder 1 made of glass fiber reinforced plastics, an aluminum end flange 2, and a silicone rubber umbrella cover 3. The silicone rubber umbrella cover 3 is composed of more than two silicone rubber umbrella covers that are sequentially injection molded. The connection structure between two adjacent silicone rubber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com