Panel/wafer molding apparatus and method of the same

A technology of packaging equipment and packaging methods, which is applied in semiconductor/solid-state device manufacturing, electrical components, and electrical solid-state devices, etc., can solve the problems of expensive packaging process, prone to warpage, and easy damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with its preferred embodiments and accompanying drawings. It should be understood that all preferred embodiments in the present invention are for illustrative purposes only. Therefore, except for the preferred embodiments in the text, the present invention It can also be widely applied in other embodiments. And the present invention is not limited to any embodiment, but should be determined by the scope of the appended claims and their equivalent fields.

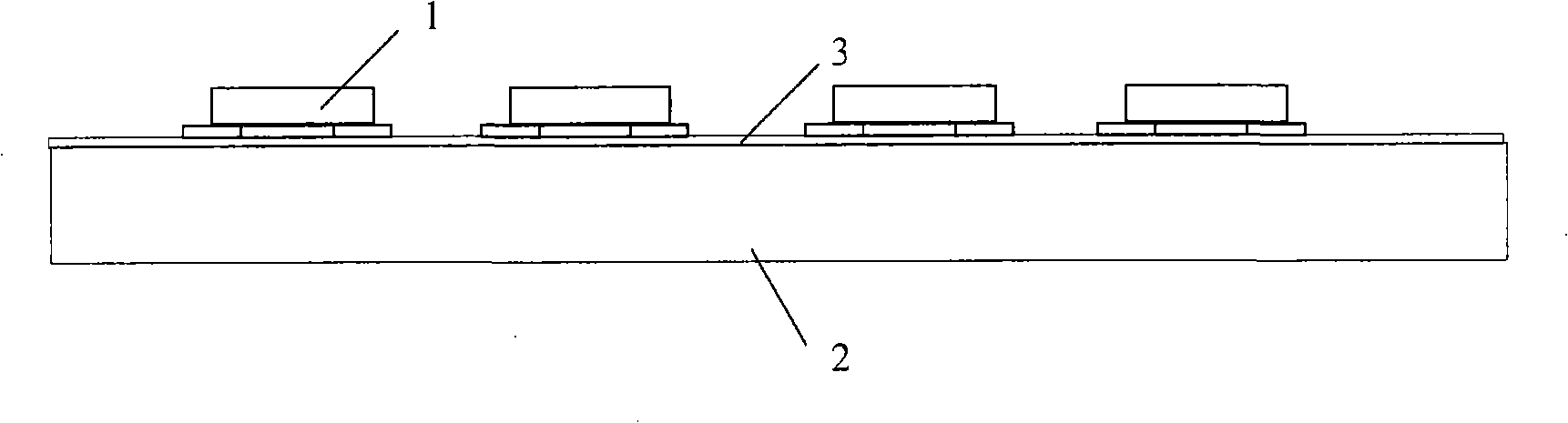

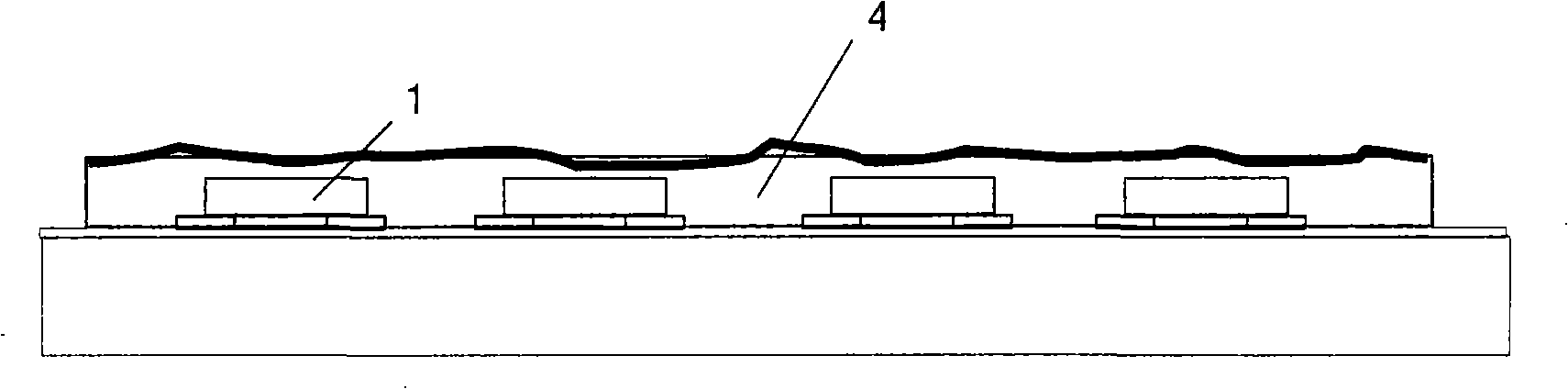

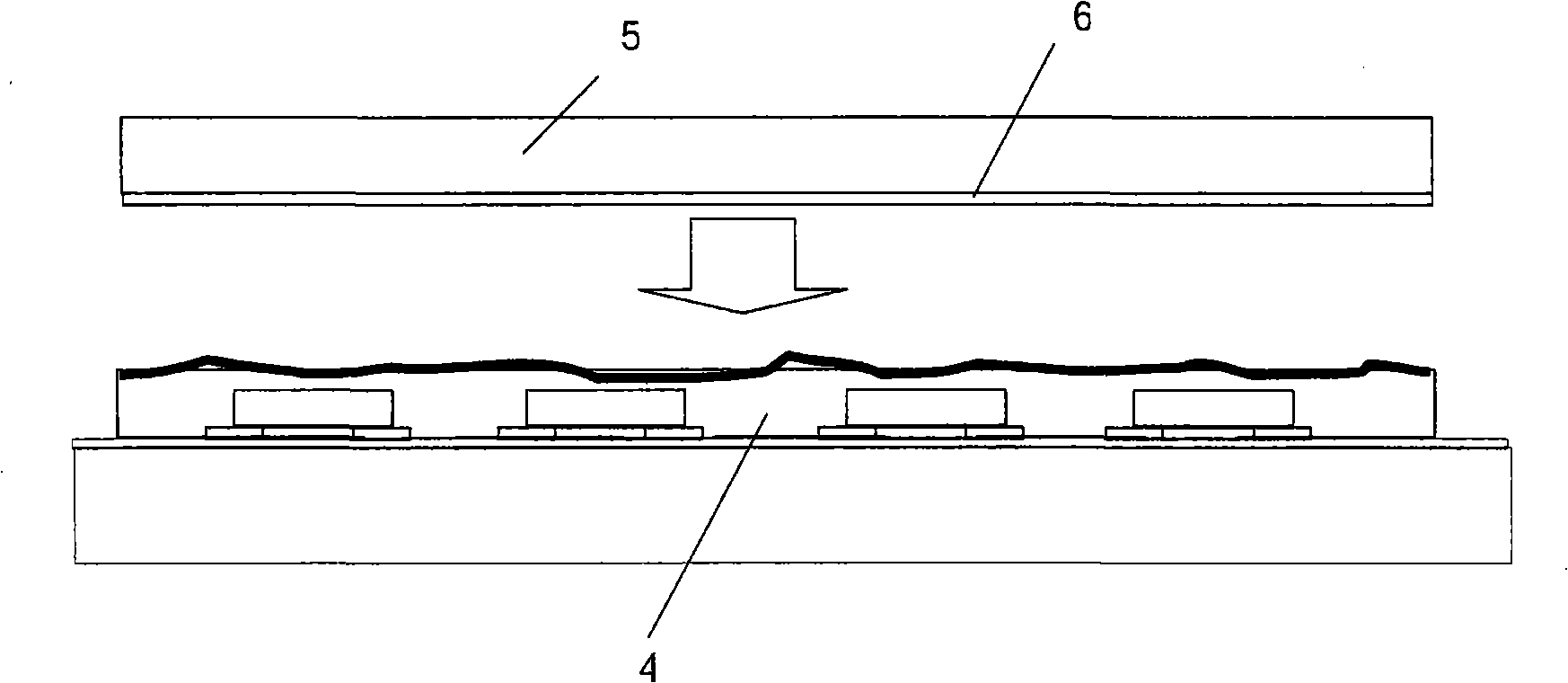

[0041] The invention discloses a flat plate / wafer structure packaging method. Such as figure 1 It is shown that the cut crystal grain 1 is redistributed on the redistribution tool 2 through the pick-up and placement and precise alignment system; wherein the lower substrate 2 of the redistribution tool includes a first separation layer 3 with an alignment pattern, forming On it, the crystal grain 1 is fixed on the first separation layer 3 with a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com