Lithography system and projection method

A lithography system and projection technology, applied in the field close to or in the range of the projection space, can solve problems such as non-optimal aberrations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

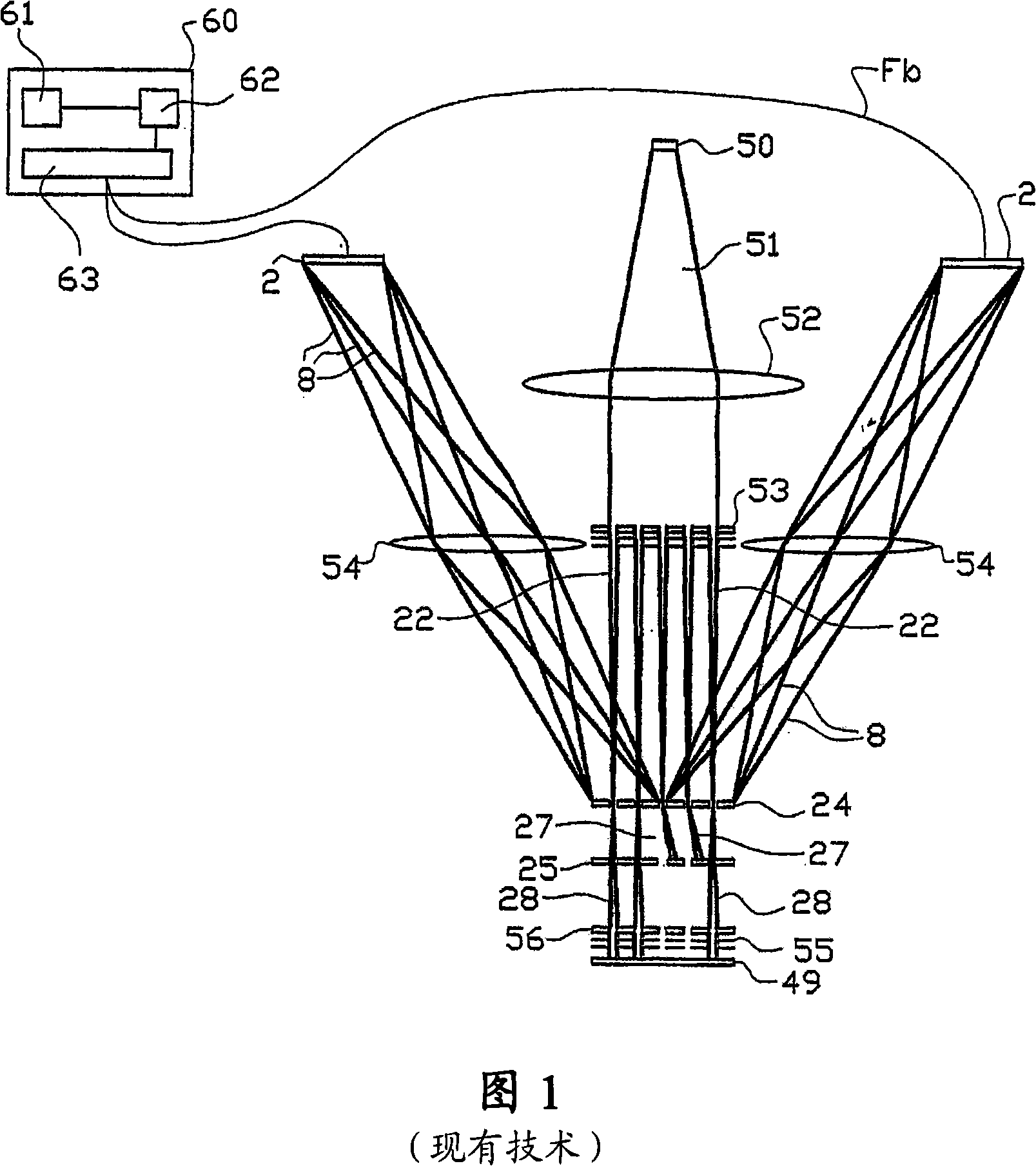

[0019] Figure 1 shows a general side view of a prior art lithographic system modified by the present invention, wherein at the modulation means end 2 of the light emitter or light carrier Fb, in particular an optical fiber Fb, using An optical system, represented by lens 54 , projects light beam 8 onto modulator array 24 . The modulated light beam 8 from each optical fiber end is projected onto a photosensitive element, ie a photosensitive part of each modulator of said modulator array 24 . Specifically, each end of the fiber Fb is projected onto the modulator array. Each beam 8 has a portion of pattern data for controlling one or more modulators, the modulation of which forms a signaling system for communicating modulator array instructions based on the pattern data to achieve the desired image on said target surface .

[0020] Figure 1 also shows a beam generator 50 which produces a diverging beam 51 of charged particles (in this example an electron beam). Using an optica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com