Liquid phase cascade rectification device for isotope separation

A technology of isotope separation and liquid phase, which is applied in the field of liquid phase cascading rectification devices, can solve the problems of affecting separation efficiency, reduction of feed liquid concentration, and inconsistency, so as to save energy, ensure separation efficiency, and avoid back mixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the examiners of the patent office, especially the public, understand the structural essence and beneficial effects of the present invention more clearly, the specific implementation of the present invention is described in detail below in conjunction with the accompanying drawings and embodiments, but the description of the embodiments does not constitute For the limitation of the technical solution of the present invention, any formal but not substantive equivalent replacement or conceptual change shall be regarded as the scope of the technical solution disclosed and claimed in the present invention.

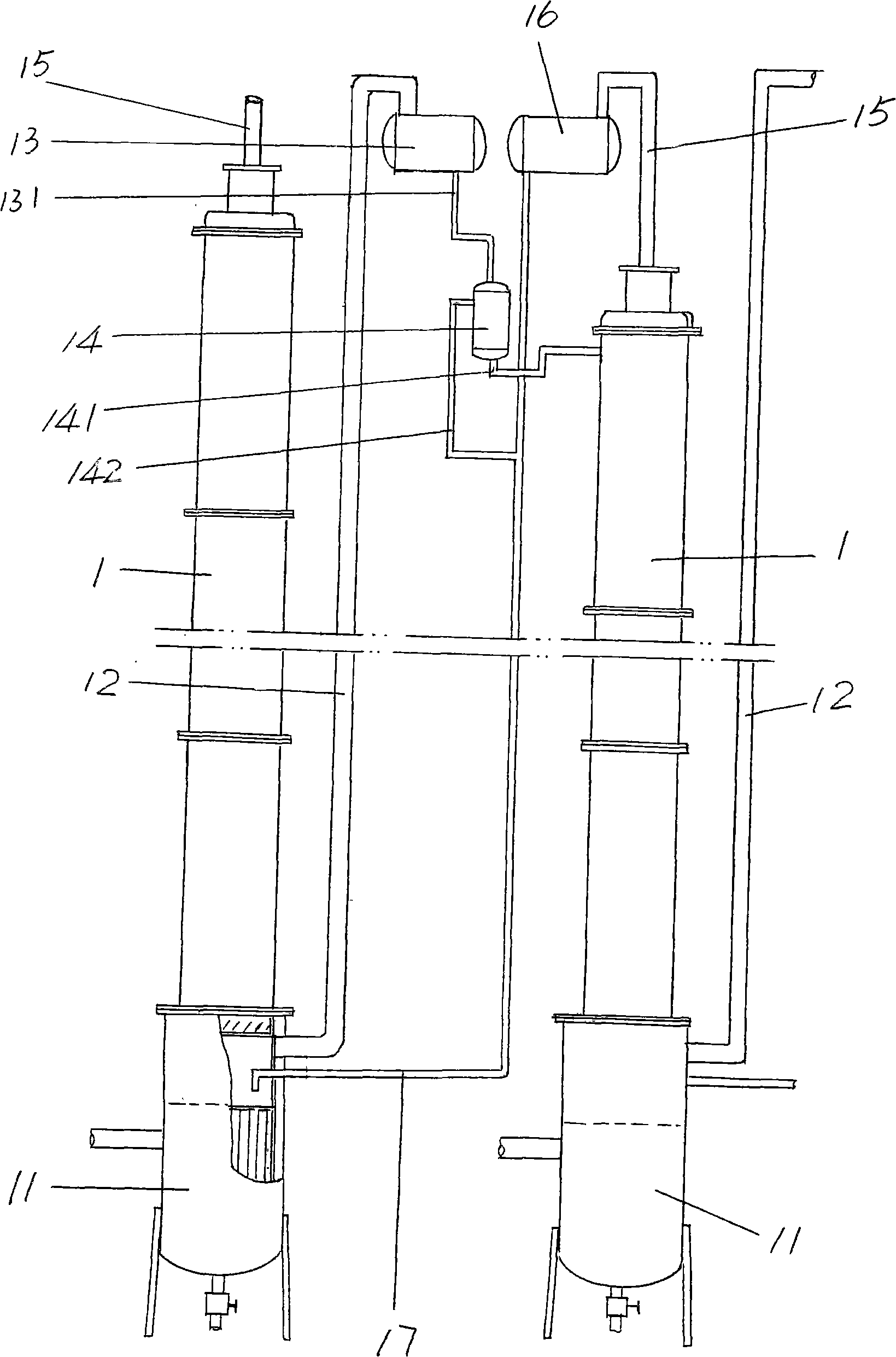

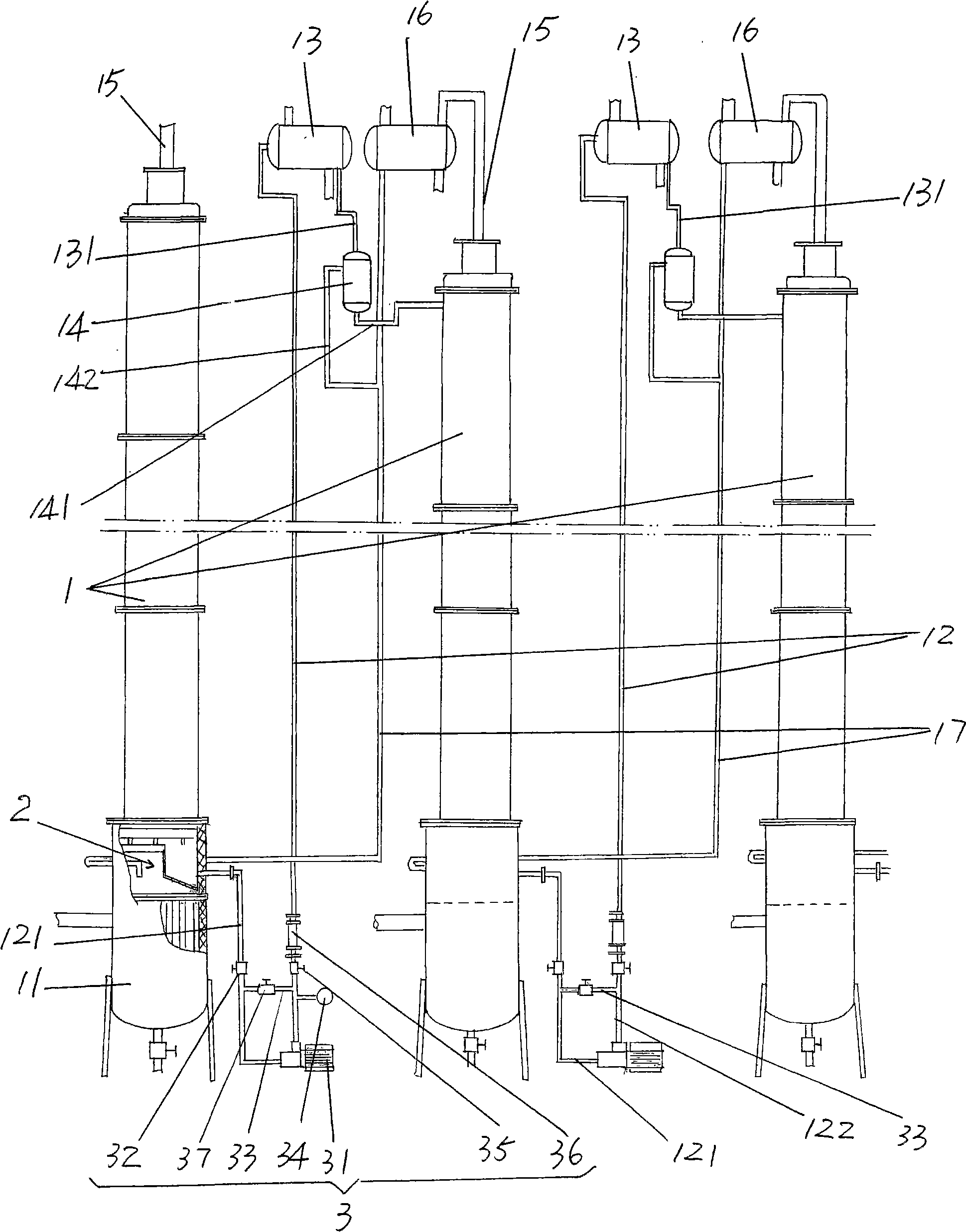

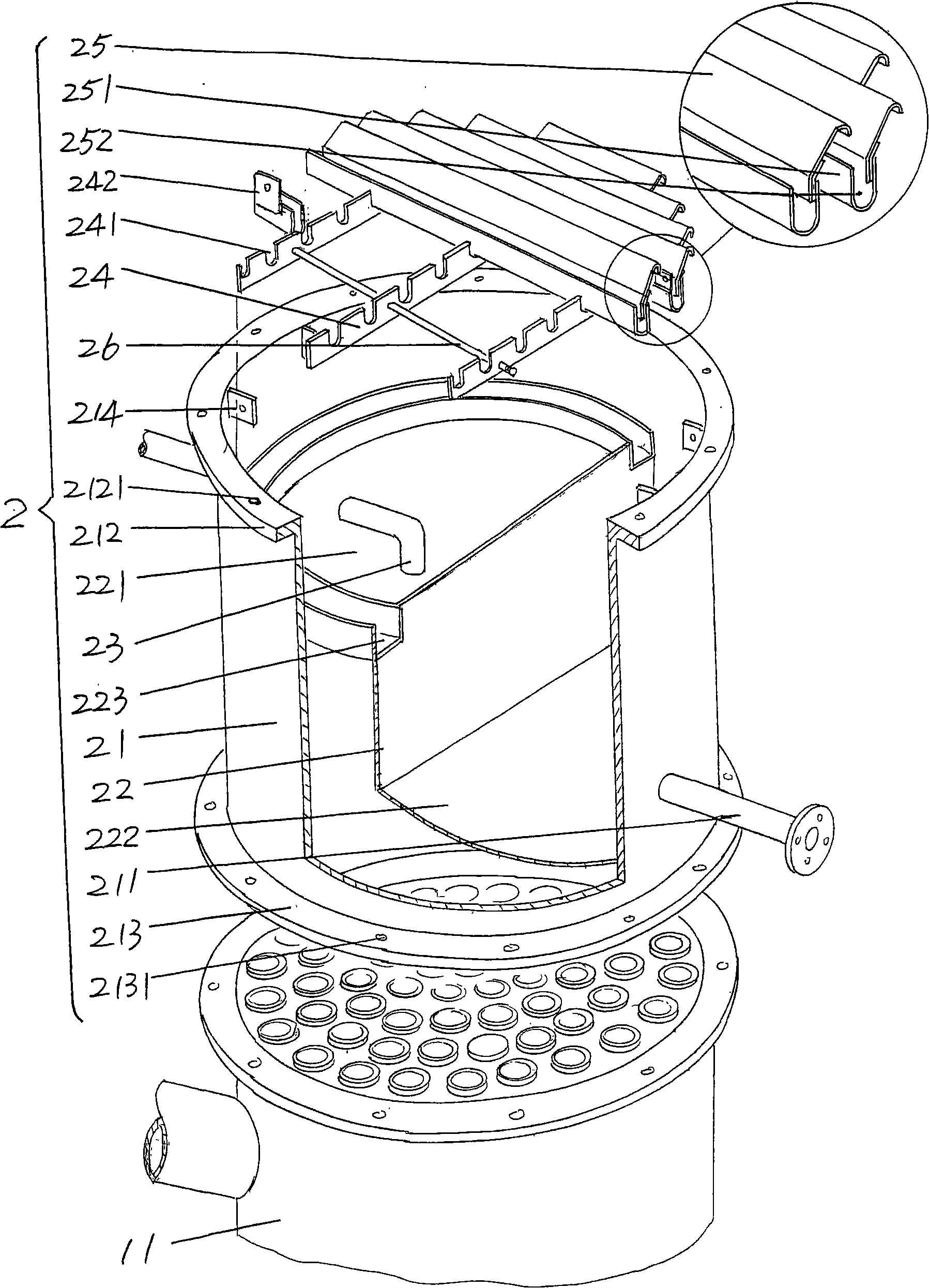

[0022] Please refer to figure 2 , a group of rectification towers 1 for isotope separation rectification, that is, separation of rectification oxygen octadecanoate from natural water, is given, although only a group of rectification towers that are three in number and connected to each other are shown in the figure 1, but the number is obviously not li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com