Magnetic punching machine

A technology of punching and magnetic force, which is applied in the field of permanent magnet and electromagnetic composite punching, can solve the problems of extra current loss, large magnetic resistance, etc., and achieve the effect of increasing frequency, high efficiency, and slowing down the accumulation of Joule heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

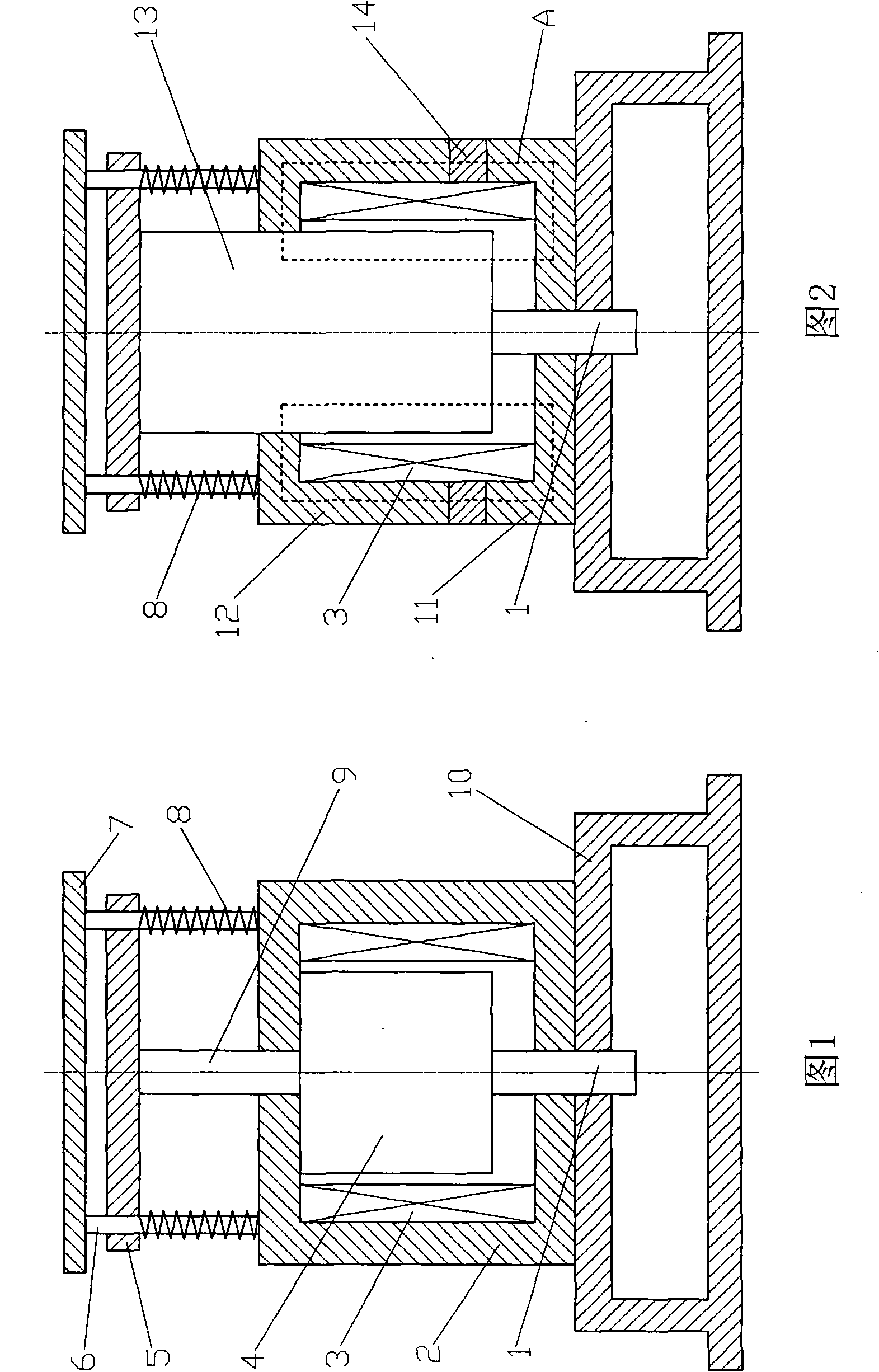

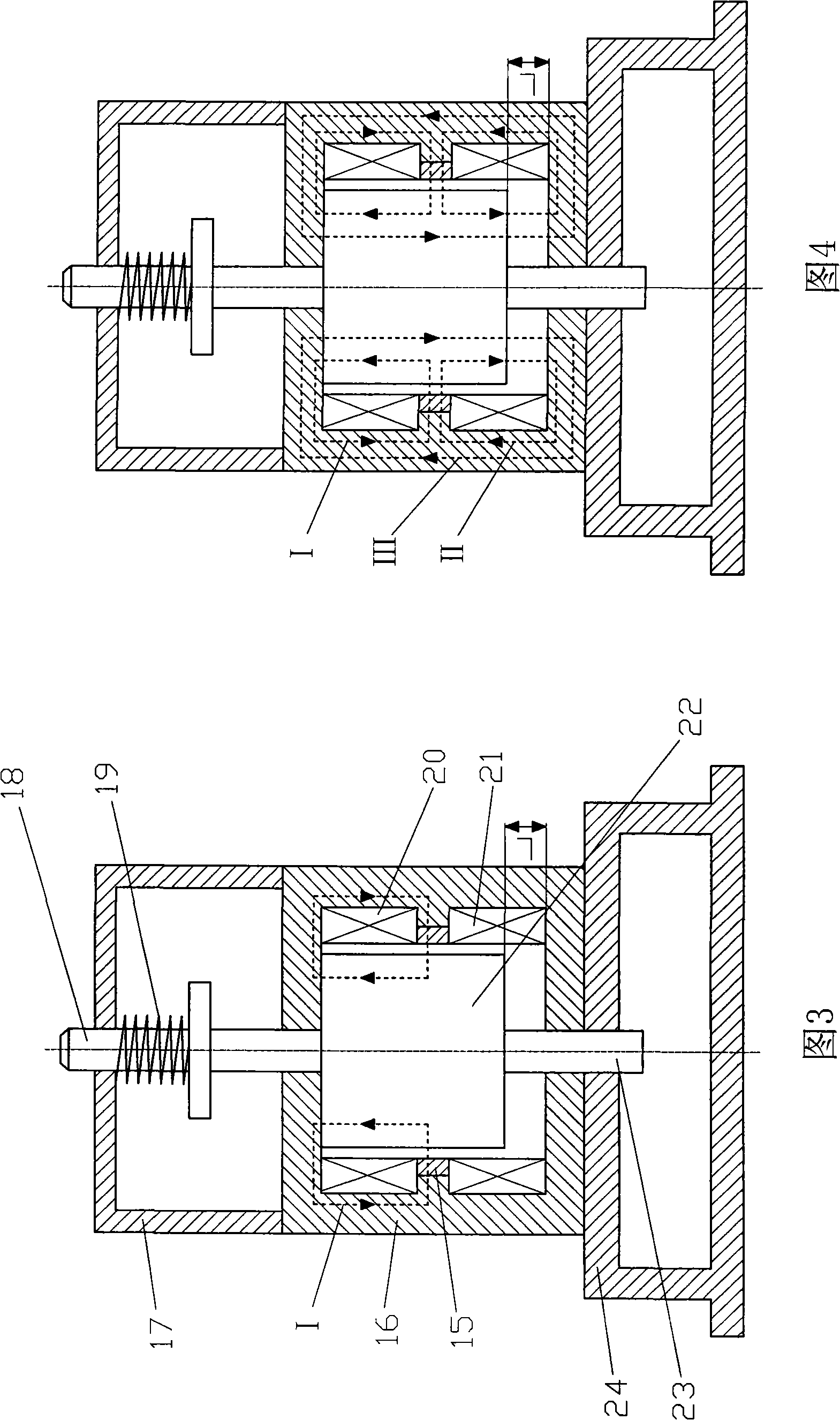

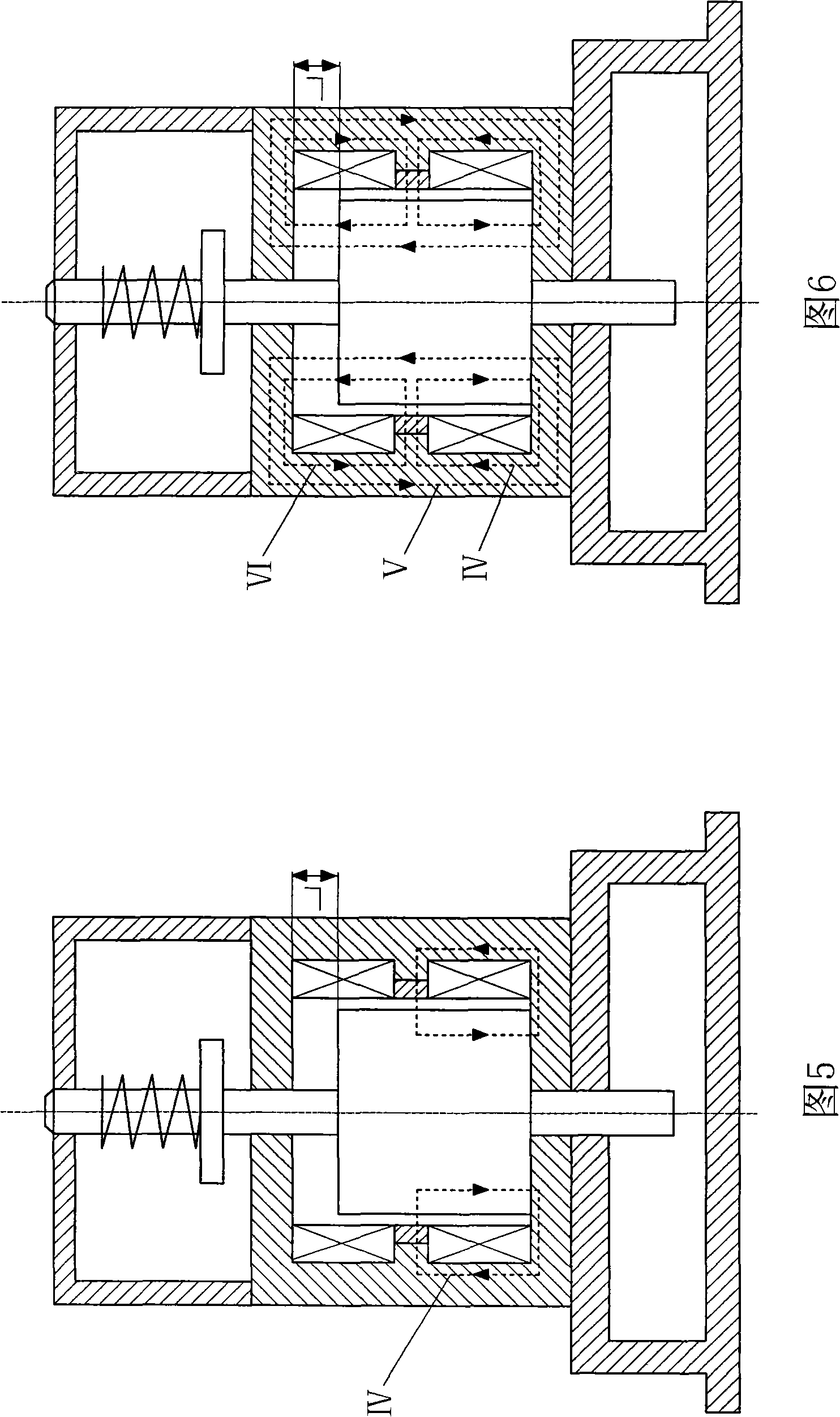

specific Embodiment approach 1

[0042] Specific embodiment one: as shown in Figure 3, on the base 24, the magnetic permeable cylinder 16 is fixed, the magnetic permeable cylinder 16 is wrapped with the upper coil 20, the radially magnetized permanent magnet ring 15, and the lower coil 21, and the moving iron core 22 is placed on them Among them, the axial length dimension of the moving iron core 22 is one stroke (L) shorter than that of the magnetic permeable cylinder 16, and there is a small gap between the outer circle of the moving iron core 22 and their inner circles, and the punch 23 and the guide rod 18 are all affixed with moving iron core 22, and above-mentioned each parts are all coaxial; Pressure spring 19 is enclosed within outside guide bar 18, and the free length of pressure spring 19 is the half of moving iron core 22 strokes (L), i.e. L / 2, The bracket 17 is fixed on the end face of the magnetic tube 16 or other parts of the bed of the punching machine. The punch 23 and the guide rod 18 form a s...

specific Embodiment approach 2

[0043] Specific embodiment two: as shown in Figure 7, the permanent magnetic ring 15 and the magnetic permeable cylinder 16 in the specific embodiment one are changed into the permanent magnetic ring 25 and the magnetic permeable cylinder 26 respectively, and the magnetic permeable lining ring 27 is added, and the others remain unchanged .

specific Embodiment approach 3

[0044] Specific embodiment three: as shown in Figure 8, the spring 19 in specific embodiment one or specific embodiment two is removed, and guide rod 18, support 17 are respectively changed into punch 31, the support 29 that is fixed with base 24, just Become a double-punch punching machine, the punch (not shown) connected to the punch 23 corresponds to the die 28, the punch (not shown) connected to the punch 31 corresponds to the die 30, and the others are unchanged, such a punch It has fully exerted its effectiveness and is extremely efficient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com