Hydraulic natural gas automobile secondary gas filling station

A technology for filling sub-stations and natural gas, applied in vehicle maintenance, vehicle maintenance/repair, transportation and packaging, etc., can solve the problems of low compression energy efficiency, high operating cost, high power consumption, etc., and achieve power saving effect Significant, significant environmental protection advantages, low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

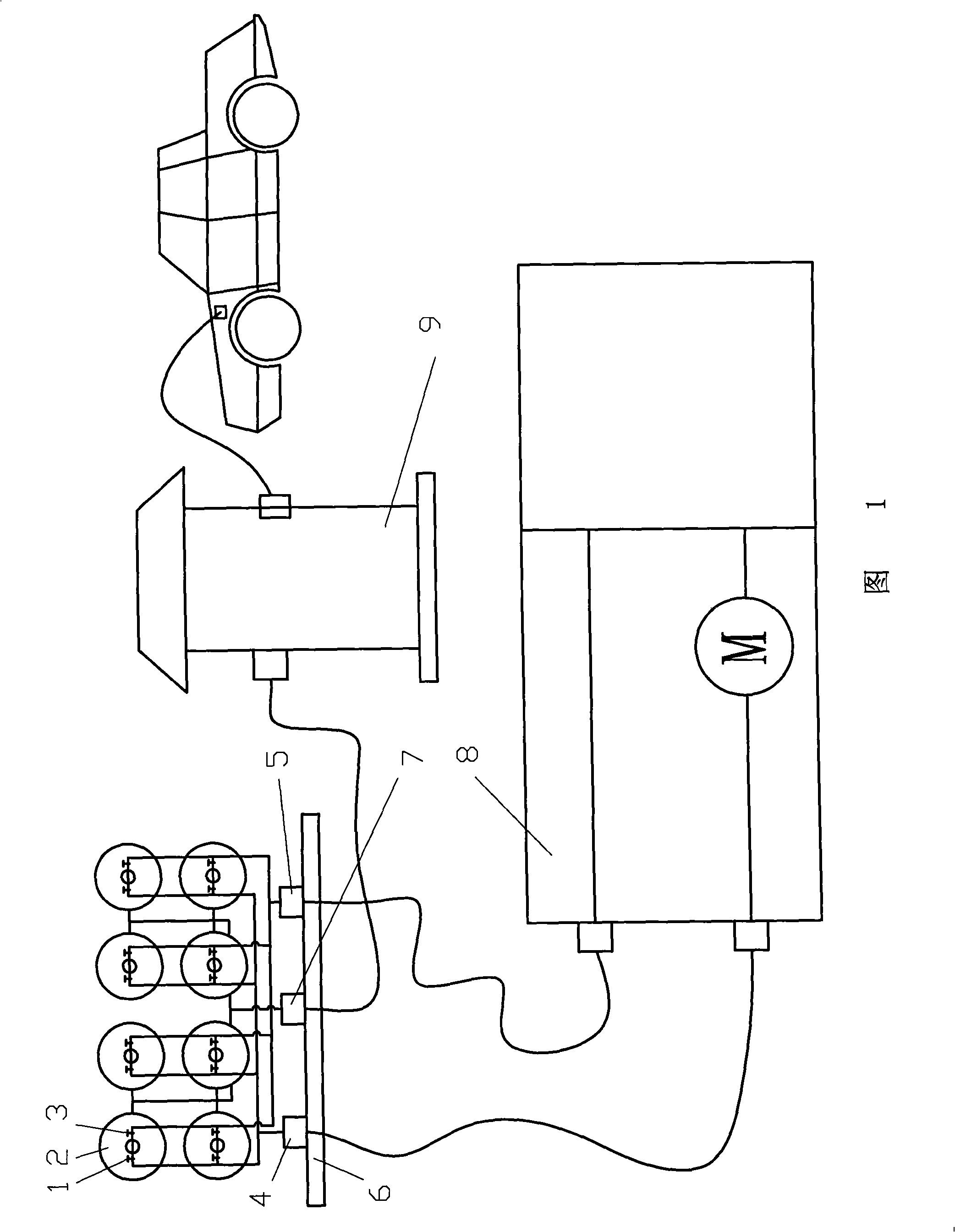

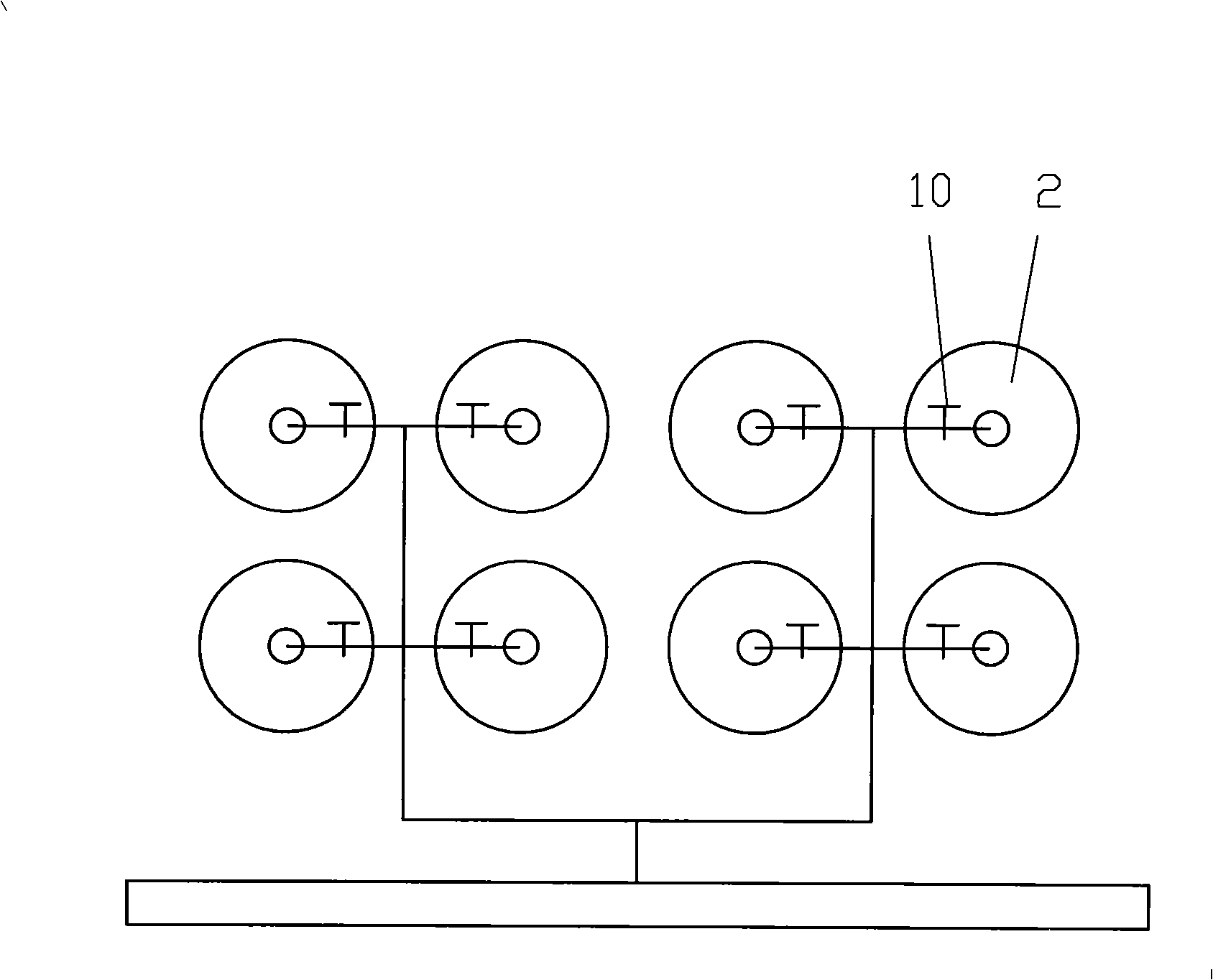

[0009] The present invention includes a CNG substation trailer 6, a substation skid body 8, a PLC control cabinet, air source equipment, a gas alarm and a gas dispenser 9, as shown in FIG. 1 .

[0010] The PLC control cabinet (not shown in the figure) is a control system with a Siemens S7-200 PLC as the core. The PLC system automatically calculates according to the numbered program, the instructions of the on-site operators and the signals detected by the instrument. Power-time data protection, data delay display and repeat display functions. The automatic work of the whole CNG substation is carried out with the touch screen, on-site buttons, and on-site sensors as the detection input signals, and the pneumatic solenoid valves and intermediate relays as the output execution signals.

[0011] The wind source equipment is composed of famous brand high-quality small compressors, molecular sieves, deep dehydration equipment, high-precision oil removal filters, etc. Its function is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com