Method for preparing visible light responding tungsten-containing semi-conductor photocatalysis material

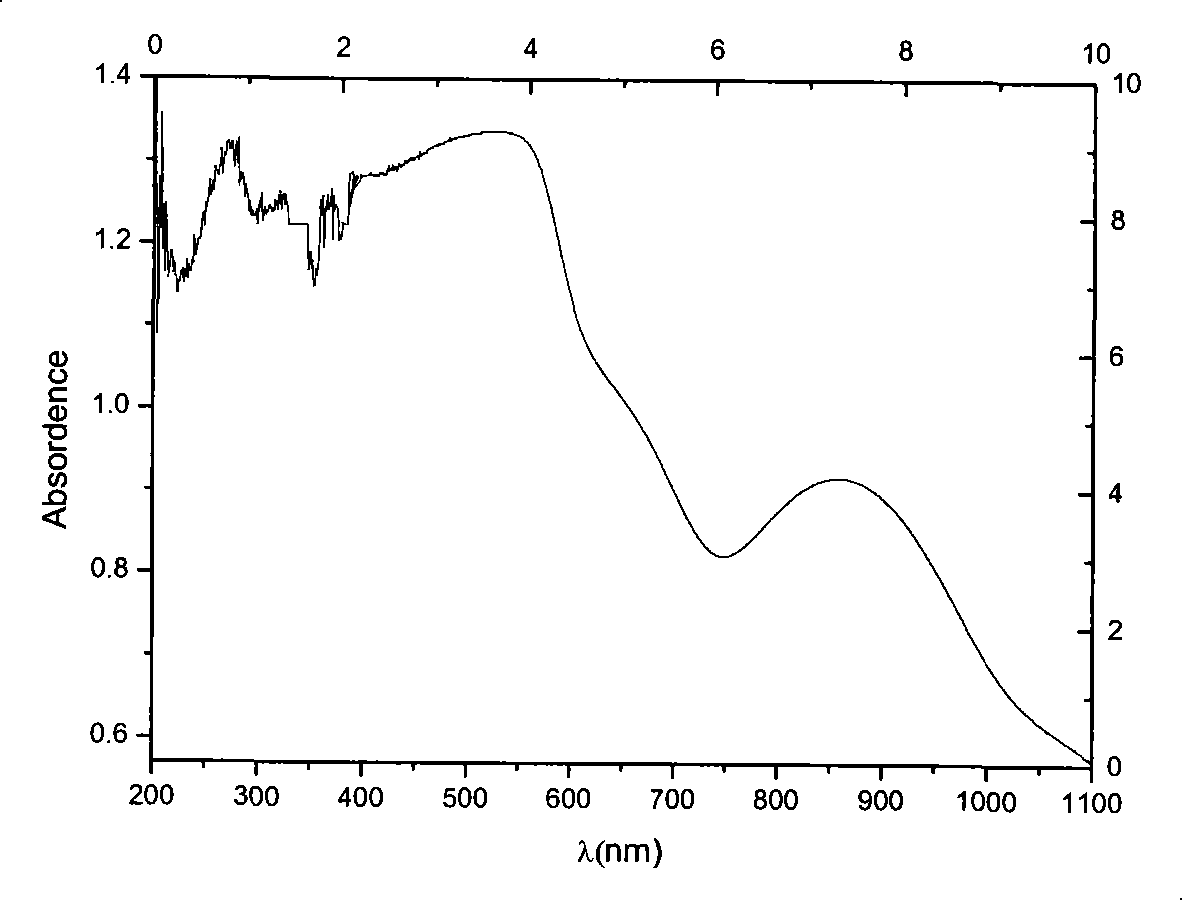

A photocatalytic material and visible light technology, applied in hydrogen production, deodorization, disinfection, etc., can solve the problems of industrial application restriction, low efficiency, inability to absorb visible light, etc., and achieve the effect of improving utilization efficiency and relieving energy pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A preparation method for a tungsten-containing semiconductor photocatalytic material responsive to visible light, comprising the steps of:

[0025] 1) Selection of raw materials:

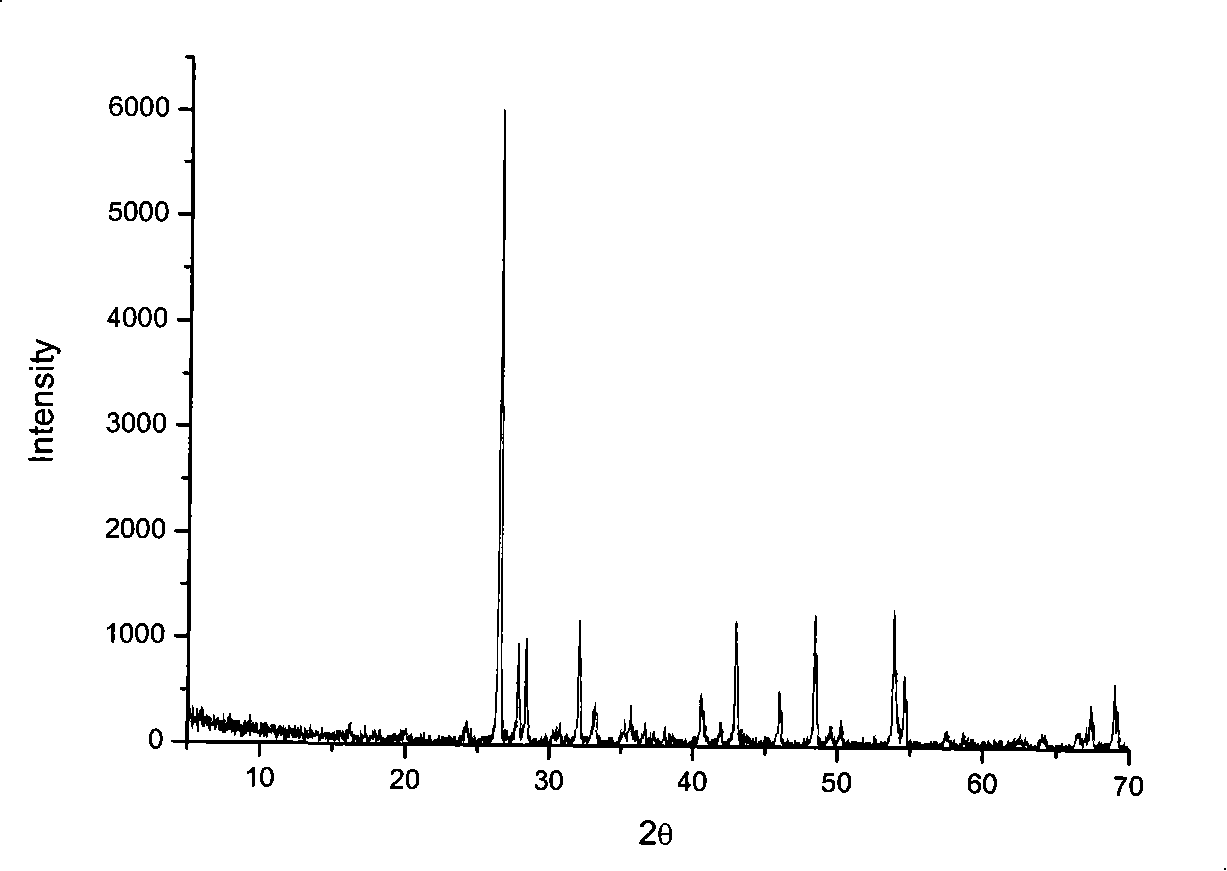

[0026] Synthesis of BaMFeWO by high-temperature solid-state reaction 6 , (M takes K element as an example)

[0027] Raw materials used (analytically pure) K 2 CO 3 1.38g,

[0028] (purity above 99.5%) WO 3 4.64g,

[0029] Analytical pure BaCO 3 3.95g,

[0030] Analytical grade FeCl 3 ·6H 2 O 5.41g,

[0031] Its chemical reaction equation:

[0032] K 2 CO 3 +2WO 3 +2BaCO 3 +2FeCl 3 ·6H 2 O→2BaKFeWO 6 +3CO 2 ↑+3H 2 O↑+6HCl↑,

[0033] K 2 CO 3 , FeCl 3 ·6H 2 O slightly excessive.

[0034] 2) After weighing the above-mentioned raw materials according to the above-mentioned doses, put them into a mortar, mix them and carefully grind them into micron-level powders, then put them into a φ10mm×20mm platinum crucible, and slowly heat up to 500°C in a mu...

Embodiment 2

[0036] A preparation method for a tungsten-containing semiconductor photocatalytic material responsive to visible light, comprising the steps of:

[0037] 1) Selection of raw materials:

[0038] Synthesis of BaMFeWO by high-temperature solid-state reaction 6(M takes K element as an example)

[0039] Raw materials used (analytical pure) KNO 3 1.01g,

[0040] (purity above 99.5%) WO 3 2.32g,

[0041] Analytical pure BaCO 3 1.97g,

[0042] Analytical grade FeCl 3 ·6H 2 O 2.70g,

[0043] Its chemical reaction equation:

[0044] KNO 3 +WO 3 +BaCO 3 +FeCl 3 ·6H 2 O → BaKFeWO 6 +CO 2 ↑+6H 2 O↑+3Cl 2 ↑+NO↑,

[0045] FeCl 3 ·6H 2 O slightly excessive.

[0046] 2) After weighing the above-mentioned raw materials according to the above-mentioned doses, put them into a mortar, mix them and carefully grind them into micron-level powders, then put them into a φ10mm×20mm platinum crucible, and slowly heat up to 500°C in a muffle furnace and p...

Embodiment 3

[0048] A preparation method for a tungsten-containing semiconductor photocatalytic material responsive to visible light, comprising the steps of:

[0049] 1) Selection of raw materials:

[0050] Synthesis of BaMFeWO by high-temperature solid-state reaction 6 (M takes K element as an example)

[0051] Raw materials used (analytically pure) K 2 SO 4 1.74g,

[0052] (purity above 99.5%) WO 3 4.64g,

[0053] Analytical grade BaCl 2 4.16g,

[0054] Analytical grade FeCl 3 ·6H 2 O 5.41g,

[0055] Its chemical reaction equation:

[0056] K 2 SO 4 +2WO 3 +2BaCl 2 +2FeCl 3 ·6H 2 O→2BaKFeWO 6 +SO3↑+H 2 O↑+10HCl↑,

[0057] FeCl 3 ·6H 2 O slightly excessive.

[0058] 2) After weighing the above-mentioned raw materials according to the above-mentioned doses, put them into a mortar, mix them and carefully grind them into micron-level powders, then put them into a φ10mm×20mm platinum crucible, and slowly heat up to 500°C in a muffle furnace an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com